Ausbrooks

KNIFE MAKER

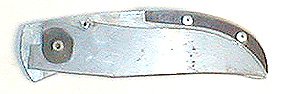

Just finished this new folder which is my second and was significantly less painful than my first but still many lessons. The lock came out good and is very smooth lock to unlock and flips open with minor wrist action. It was a fun build as I wanted to try some of my mokume and some jigged bone that was PP treated.

Specs: 3" .135 BG42 SS blade, 64RC, .062 Ti frame, raindrop mokume bolsters, SS pivot, teflon washers, amb. thumb studs, bone scales.

All comments and critiques welcome and thanks for lookin'.

Specs: 3" .135 BG42 SS blade, 64RC, .062 Ti frame, raindrop mokume bolsters, SS pivot, teflon washers, amb. thumb studs, bone scales.

All comments and critiques welcome and thanks for lookin'.