MTBob

Well-Known Member

This posting is related to an earlier posting I did on Polymorph Plastic and is still a WIP. I want to use this posting to focus on the technique of blind hole location.

I'm working on a cleaver handle and want to put an end cap on the handle. There are a bunch of ways to do this, but I wanted to try using blind pins between the wood and G-10 end cap to provide more strength to an otherwise questionable unsupported epoxy glue line.

The problem is how do you get pins to line up in a blind fit (2 mating surfaces in which the pins are not revealed)? Here's how I did it... and it worked.

I warmed up the plastic and pressed the wood and G-10 material into it, leaving a thin inner web of plastic between the wood and G-10. Alignment of the two pieces is important so that the mating outside surfaces are relatively parallel. I eye balled it since I have some excess material to work with on both parts.

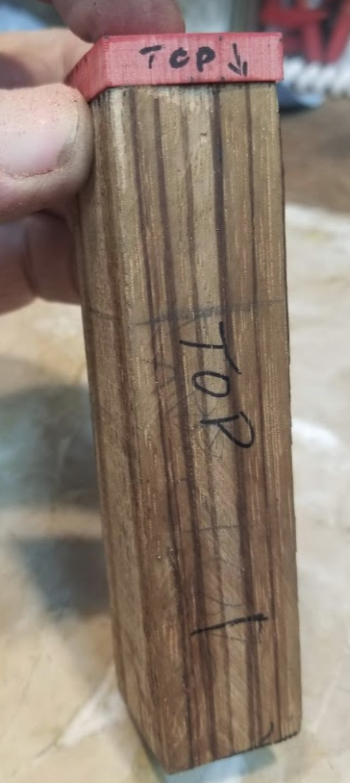

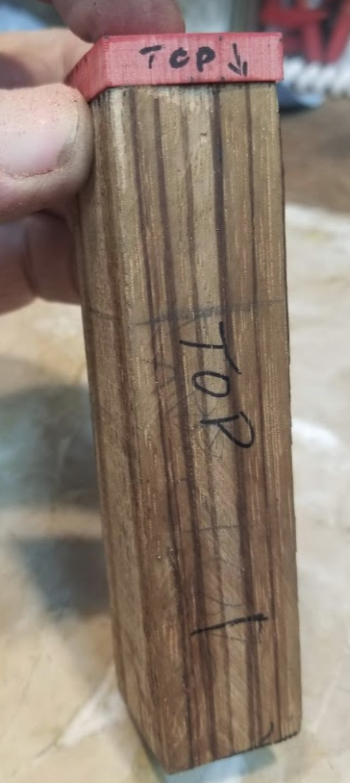

Showing the plastic form after cooling with the shape of both parts accurately set in the plastic with a thin web in the center

I then located pin placement, leaving ample room for handle contouring. In this case the actual pin location does not need to be precise, but the pin orientation / alignment between mating parts needs to be relatively accurate.

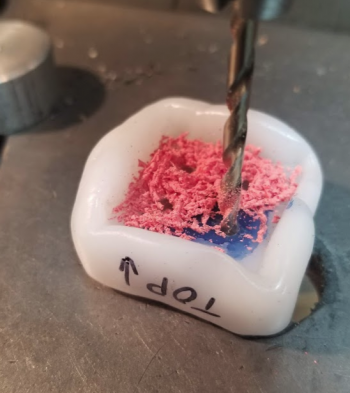

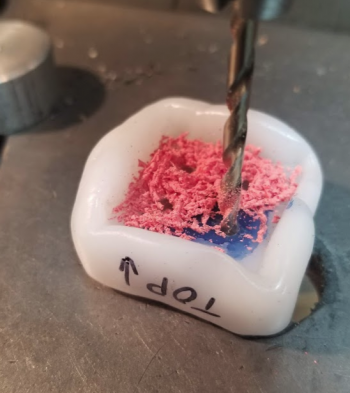

Using those pin locations I drilled the wood and G-10, about 1" into the wood and about 1/16 into the G-10

This shows the finished pin locations in both parts, prior to glue up. Both surfaces were roughened even more before glue up, with small shallow holes drilled in both parts to accept additional epoxy.

I'm working on a cleaver handle and want to put an end cap on the handle. There are a bunch of ways to do this, but I wanted to try using blind pins between the wood and G-10 end cap to provide more strength to an otherwise questionable unsupported epoxy glue line.

The problem is how do you get pins to line up in a blind fit (2 mating surfaces in which the pins are not revealed)? Here's how I did it... and it worked.

I warmed up the plastic and pressed the wood and G-10 material into it, leaving a thin inner web of plastic between the wood and G-10. Alignment of the two pieces is important so that the mating outside surfaces are relatively parallel. I eye balled it since I have some excess material to work with on both parts.

Showing the plastic form after cooling with the shape of both parts accurately set in the plastic with a thin web in the center

I then located pin placement, leaving ample room for handle contouring. In this case the actual pin location does not need to be precise, but the pin orientation / alignment between mating parts needs to be relatively accurate.

Using those pin locations I drilled the wood and G-10, about 1" into the wood and about 1/16 into the G-10

This shows the finished pin locations in both parts, prior to glue up. Both surfaces were roughened even more before glue up, with small shallow holes drilled in both parts to accept additional epoxy.