You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

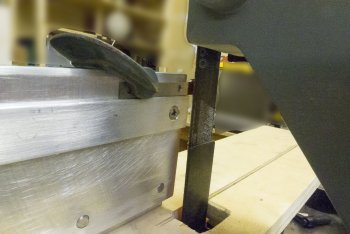

Bevel Grinding Jig

- Thread starter Chris623

- Start date

Chris623

Well-Known Member

Well, I had a chance to give'er a go and this will work perfectly for my needs. Hand sanded the blade to a 1000 grit and the bevel has proven to be absolutely flat and uniform on both sides. I'm grinnin' like a kid at Christmas. Can't wait to harden this blade and do the final sanding and get a handle on it. Since I'm so new to all of this, I hope I left enough thickness at the edge so I won't ruin it during hardening. We'll see-e-e-e...................... Won't be able to get to that part until tomorrow, but I'm sure antsy, to say the least.

The nice part about this jig is I'll be able to remove the "shelf" and put another on it if I want to make larger knives............which I hope to do in the future. I know the skill of free-hand beveling is "the rage", but as few larger knives as I'm likely to make, the more comfortable I'll be with the jig. It's more important to me to have a uniform bevel than it is to brag "I did it free-hand".

The nice part about this jig is I'll be able to remove the "shelf" and put another on it if I want to make larger knives............which I hope to do in the future. I know the skill of free-hand beveling is "the rage", but as few larger knives as I'm likely to make, the more comfortable I'll be with the jig. It's more important to me to have a uniform bevel than it is to brag "I did it free-hand".

John Wilson

Well-Known Member

Well, I had a chance to give'er a go and this will work perfectly for my needs. Hand sanded the blade to a 1000 grit and the bevel has proven to be absolutely flat and uniform on both sides. I'm grinnin' like a kid at Christmas. Can't wait to harden this blade and do the final sanding and get a handle on it. Since I'm so new to all of this, I hope I left enough thickness at the edge so I won't ruin it during hardening. We'll see-e-e-e...................... Won't be able to get to that part until tomorrow, but I'm sure antsy, to say the least.

The nice part about this jig is I'll be able to remove the "shelf" and put another on it if I want to make larger knives............which I hope to do in the future. I know the skill of free-hand beveling is "the rage", but as few larger knives as I'm likely to make, the more comfortable I'll be with the jig. It's more important to me to have a uniform bevel than it is to brag "I did it free-hand".

Free hand grinding on a 1x30 is probably not realistic in a lot of cases. It’s easy on a 2x72 because the machine is huge and heavy by comparison, the platen is stiff, and the belt doesn’t flutter all over the platen when you put pressure on it.

If you can make knives on a 1x30, making them on a 2x72 is like reclining the seat in a Cadillac and playing some Kenny G while cruising down the interstate.

Great work on the jig. Getting the blade up into the slack belt is good thinking.

Chris623

Well-Known Member

Yup, I know I'm going to end up with a 2x72.................but that's in the future.

On a side note, I joined a local group of blacksmiths who meet once a week at a guys shop near my place to use his tools and equipment. Has about 6 forges, 2 2x72 grinders, more anvils than I've ever seen in one room, 4 power hammers and one that looks like a friggin dinosaur..............stands at least 10 foot high and must weigh more that 4 Cadillac sedans and a 2x72 surface grinder. About 10 or 11 guys show up and forge all evening long. A bunch of them have made 2x72 grinders, so I'm sure I can get some guidance in building one myself. Looks as if that's where I'm going to be spending my Thursday nights. While I understand most are involved in just iron work at the forges, I understand several are knife makers, so I'm hoping this turns out to be a real journey of learning. I'm going to start next Thursday to make a pair of flat tongs for when I build my forge.

While I understand most are involved in just iron work at the forges, I understand several are knife makers, so I'm hoping this turns out to be a real journey of learning. I'm going to start next Thursday to make a pair of flat tongs for when I build my forge.

On a side note, I joined a local group of blacksmiths who meet once a week at a guys shop near my place to use his tools and equipment. Has about 6 forges, 2 2x72 grinders, more anvils than I've ever seen in one room, 4 power hammers and one that looks like a friggin dinosaur..............stands at least 10 foot high and must weigh more that 4 Cadillac sedans and a 2x72 surface grinder. About 10 or 11 guys show up and forge all evening long. A bunch of them have made 2x72 grinders, so I'm sure I can get some guidance in building one myself. Looks as if that's where I'm going to be spending my Thursday nights.

Nick Riggi

Well-Known Member

I started with my bevel jig that I sell and a 1x30. Learning the process and angles with the jig helped me progress to freehand grinds. I was able to get decent grinds with the 1x30 but couldn't apply the kind of pressure needed because I would stall the motor

Now having a 2x72 makes a world of difference.

Now having a 2x72 makes a world of difference.

Nick Riggi

Well-Known Member

Understood. The size I usually make normally posed an issue with the underpowered motor.As small as my blades are on carving knives, Nick, I'm fortunate I don't have to apply much pressure because as you mention, the 1x30 won't take it.

Smallshop

KNIFE MAKER

LOL...there you go again Wilson!....is like reclining the seat in a Cadillac and playing some Kenny G while cruising down the interstate.

Sean Jones

Well-Known Member

Looks good!

BrandantR

Well-Known Member

Nice one, Chris! That little knife will make some great chips. I got my start into knife making when I was really into woodcarving. I made and sold hundreds of knives made from floor scraper blades. I found my way into custom knives and have been hooked ever since. It's nice to have a fellow woodcarver here with us.