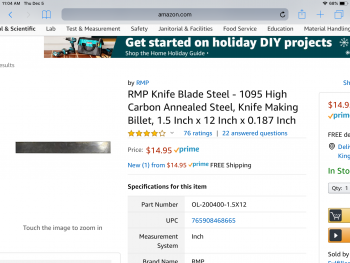

From the seller description: "Made from high carbon steel, this RMP knife billet sharpens easily, resists chipping, and holds a great edge."

They should probably mention that it needs to be properly heat treated first.

Couple of things:

It very likely could be your source. There's no telling where they get it from, what kind of quality control they get, or the actual annealing process used.

Quality saw blades will definitely make a difference. It's also important to make sure you're breaking your blades in properly. If you're using a porta-band, they're probably not as straightforward to break in as a larger horizontal or vertical saw, but basically you'll want to select your slowest speed and take light pressure cuts for a bit. On larger blades, the manufacturers typically recommend something like 100 inches of cut or so, but I imagine a smaller blade would be around 1/2 that.

What "break in" does is very slightly round over the point of each tooth so that it goes through the material more smoothly. If you force a fresh saw tooth too hard at first, it will dig into the material and fracture, dulling your blade faster.

A little bit of cutting lube will help as well. There are "lube sticks" which work well for saw blades, though I don't recall any brands at the moment, but occasionally I'll just brush a little bit of cutting oil on the outside periphery of my blade, so that it doesn't get onto the tires of my saw as much. It makes a noticeable difference in needed cutting pressure.

Also, make sure you're using a proper TPI for the material you're cutting. You want at least 2-3 teeth in the material at any given moment. If your blade is too coarse, it may cut well initially, but you'll inevitably dull the teeth a lot faster, if not break them off altogether.

Lastly, let the blade do the cutting. If you push too hard, you'll load and wear the blade out much faster than if you let the blade do the work and clear your material at a proper pace. Feeds and speeds aren't just for drills and mills, but for ANY cutting tool. If your blade is getting too hot, you're already done.