I'm new to this and have been doing my homework as to which awl to start hand stitching with.

There is no local store to actually physically view tools prior to purchase.

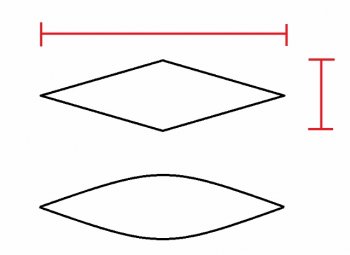

Instead of buying, I decided to make my own diamond awl, but would really appreciate a little help and input from veterans here.

Question 1:

For typical knife sheath making, what thickness and width should I aim for ?

Question 2:

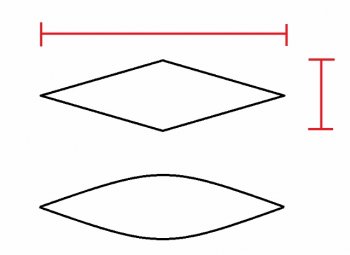

From what I've read, one is only supposed to sharpen the two side edges of the diamond, so could the leaf shape pictured above work as well?

Question 3:

When people say outer edges should be sharp...are we talking about paper-slicing sharp?

Question 4:

Should the point be rounded and needle-like or flat and chisel-like?

Question 5:

The main shaft of the awl should be of uniform diamond shape, but what length should the point-to-main shaft be?

There is no local store to actually physically view tools prior to purchase.

Instead of buying, I decided to make my own diamond awl, but would really appreciate a little help and input from veterans here.

Question 1:

For typical knife sheath making, what thickness and width should I aim for ?

Question 2:

From what I've read, one is only supposed to sharpen the two side edges of the diamond, so could the leaf shape pictured above work as well?

Question 3:

When people say outer edges should be sharp...are we talking about paper-slicing sharp?

Question 4:

Should the point be rounded and needle-like or flat and chisel-like?

Question 5:

The main shaft of the awl should be of uniform diamond shape, but what length should the point-to-main shaft be?