You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anybody ever used electric sanders for flats?

- Thread starter SHOKR

- Start date

I'll admit it, I've used my electric DA sander and it actually works pretty good. There will be some hand sanding at the end but to get you to the final finish sanding it's great. I will also admit I just picked up one of the triangular oscillating sanders and will try it this weekend. I think it will be easier to control than the DA orbital. I'll probably have to hand cut paper due to the lack of pre-cut stuff for metal.

rhinoknives

Well-Known Member

Shokr,

Look around Ed Caffery's forum or how toos? I remember a thread where he modified an electric palm sander for doing flats with a piece of Micarta and gets great results. If you find it? Please let me know?

Look around Ed Caffery's forum or how toos? I remember a thread where he modified an electric palm sander for doing flats with a piece of Micarta and gets great results. If you find it? Please let me know?

KCorn

Well-Known Member

Man I am so glad that y'all brought this up. I actually modified one of my hand sanders with the micarta base to do flats a while back and forgot about using it. I'm trying to finish several knives for Christmas gifts and that will save me some much needed time. I think it was an Ed Caffrey thread where I saw it. Bruce Evans has a post about how to do it over on blade forums as well.

Laurence, I didn't read the whole thread yet but I think I found the one you were talking about.

http://knifedogs.com/showthread.php?10323-Frustration-Discovery!&highlight=sander

Aaron

http://knifedogs.com/showthread.php?10323-Frustration-Discovery!&highlight=sander

Aaron

rhinoknives

Well-Known Member

Laurence, I didn't read the whole thread yet but I think I found the one you were talking about.

http://knifedogs.com/showthread.php?10323-Frustration-Discovery!&highlight=sander

Aaron

Ahmed,

Aaron found the thread I was referring too! Good work!

SHOKR

Well-Known Member

Thanks a lot guys

The ones i thought would work are the oscillating and thecrandom, i had a very quick look at them today at the market and i think the random might be to soft, so was going to check the oscillating. Triangular would be soft too?

Laurence, i remember that thread, but i think it was bit too domplex for me. I'll give it another read and see

I have lots of blades to finish and no hope for surface grinding (they were surface ground badly, so have little waves and i have to start for an hour or so with 80g) so its definitely worth buying sander for it

The ones i thought would work are the oscillating and thecrandom, i had a very quick look at them today at the market and i think the random might be to soft, so was going to check the oscillating. Triangular would be soft too?

Laurence, i remember that thread, but i think it was bit too domplex for me. I'll give it another read and see

I have lots of blades to finish and no hope for surface grinding (they were surface ground badly, so have little waves and i have to start for an hour or so with 80g) so its definitely worth buying sander for it

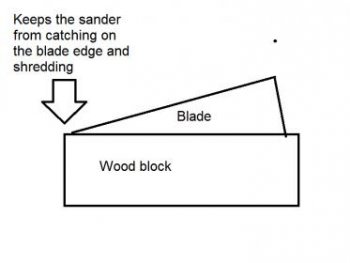

One other thing I found that keeps from shredding paper when using an 'un-modified' sander is to clamp the blade to a piece of wood so the contact side is flat on the wood and the edge is about 1/8 from the edge of the wood. This keeps the paper from getting snagged on the blade and allows me to hold the DA sander with both hands.

SHOKR

Well-Known Member

Laurence, i read Ed's post now and this time it made sense, i guess since i didnt need it much before didnt pay much attention, thanks for reminding me of it

Thanks Roger. Sorry, i dont get how the 1/8 space would keep paper from getting torn?

Anyway i will give the sander a try and see

Thanks Roger. Sorry, i dont get how the 1/8 space would keep paper from getting torn?

Anyway i will give the sander a try and see

rhinoknives

Well-Known Member

Skohr,

I have a Makita brand square osculating sander in bound as of last night. I would recommend one of the square units for better use of sandpaper.

I have a Makita brand square osculating sander in bound as of last night. I would recommend one of the square units for better use of sandpaper.

N.N

Well-Known Member

I use to use one all the time on wood handles. Mine broke down though so I've been using the belts. But belts cut so quick, I bet it would be easier to get the grain in micarta to match because it doesn't take off so much, so quick. I might try that on my next micarta handle. Thanks for the idea.

So I wonder how it would look to finish steel like that with a "satiny" look? Kinda similar to stonewashed? Or would it look like junk?

So I wonder how it would look to finish steel like that with a "satiny" look? Kinda similar to stonewashed? Or would it look like junk?

SHOKR

Well-Known Member

Thanks, Laurence

I thought they all had a standard size? But i will do bit more researxh before i buy. Probably will go with cheaper brand anyway, market is filled with chinese stuff

Roger

Thanks a lot buddy, since i mainly wanted it for the flats i didnt catch what you meant, lack of imagination on my part. I mostly do hollow hrinding now, but will sure try your advice on next flat blade (which just might be a chopper in the works now)

N N

I never used it so dont know, however i dont believe the finish would be good, this is mainly to save a lot of energy and time so finishing by hand would much easier, you might want to check the lonk posted few posts bove for more info

I thought they all had a standard size? But i will do bit more researxh before i buy. Probably will go with cheaper brand anyway, market is filled with chinese stuff

Roger

Thanks a lot buddy, since i mainly wanted it for the flats i didnt catch what you meant, lack of imagination on my part. I mostly do hollow hrinding now, but will sure try your advice on next flat blade (which just might be a chopper in the works now)

N N

I never used it so dont know, however i dont believe the finish would be good, this is mainly to save a lot of energy and time so finishing by hand would much easier, you might want to check the lonk posted few posts bove for more info

rhinoknives

Well-Known Member

Shokr,

Here is the USA, some are round and some square. The square base is 1/4 of a sheet of sandpaper. Most here are made in china as well.

Here is the USA, some are round and some square. The square base is 1/4 of a sheet of sandpaper. Most here are made in china as well.

rhinoknives

Well-Known Member

The square kind will be much less expensive to feed with sandpaper.

SHOKR

Well-Known Member

i bought a 1/3 sander and so far made two trials

one was holding 120g with the sander clamps, that didnt work too well, only the front and back were effective but the middle part was bit too slack

my second trial was using spray adhesive, it was bit better but not good enough and it wasnt even (i was trying to remove really deep scratches from bad surface grinder)

so next i will try something someone told me about, hold the sander upside down in a vise, and hold the work piece in my hand. i am hoping that would give me better control, if that doesnt work i will try removing the foam and using a piece of G10 or micarta and trying again

one was holding 120g with the sander clamps, that didnt work too well, only the front and back were effective but the middle part was bit too slack

my second trial was using spray adhesive, it was bit better but not good enough and it wasnt even (i was trying to remove really deep scratches from bad surface grinder)

so next i will try something someone told me about, hold the sander upside down in a vise, and hold the work piece in my hand. i am hoping that would give me better control, if that doesnt work i will try removing the foam and using a piece of G10 or micarta and trying again

Ahmed,

Do yourself a favor and get rid of the foam for your application on steel. You want a rigid surface, (g10/micarta) to get rid of the ripples. Later, if you like using the sander, you can set up another with a thin cork surface on the g10 or micarta for when you want to do some blending, and need a little give as you sand. Spray adhesive is the way to go.

It leaves a sanded surface with J or fish hooks that can be hand sanded away very easily.

I did one some time ago, but I used either Plexiglas or polycarbonate not sure which, because I had it on hand.

Fred

Do yourself a favor and get rid of the foam for your application on steel. You want a rigid surface, (g10/micarta) to get rid of the ripples. Later, if you like using the sander, you can set up another with a thin cork surface on the g10 or micarta for when you want to do some blending, and need a little give as you sand. Spray adhesive is the way to go.

It leaves a sanded surface with J or fish hooks that can be hand sanded away very easily.

I did one some time ago, but I used either Plexiglas or polycarbonate not sure which, because I had it on hand.

Fred

Last edited: