Tim Musselman

Well-Known Member

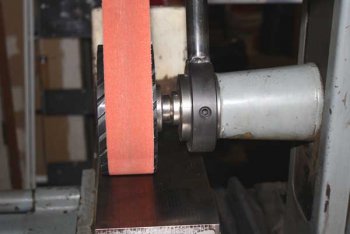

Thought I would share this conversion since it doesn't require a lot of machining mostly off the shelf stuff and some welding, drilling and tapping.

The wheels came from www.sunray-inc.com the rest from the local hardware store except the collar that came from MSC.

The collar fits on the flat that the wheel guard attaches to it is a snug fit and has a set screw to secure it which seems to work really well.

The main tube is 3/4" black pipe welded to the collar with a 3/4" rod that slides inside holds the idler wheel a compression spring in the tube below the rod provides tension for the belt by the way crowning the tracking wheel makes a huge difference controlling tracking.

Now for the tracking instead of rocking the idler wheel I took the same approach that my 1 X 42 kalamazoo grinder used and twist the idler wheel to track the belt it means you have to have the belt pretty well lined up to get started but once you get the hang of it it works really well. Once you have the tracking where you want it a 1/4" locking screw keeps it that way I just tapped the black pipe for the screw but you could weld a nut on if you felt you needed more threads.

The whole assembly seems really solid with no vibration at the idler wheel and wow what a difference over grinding wheels.

The wheels came from www.sunray-inc.com the rest from the local hardware store except the collar that came from MSC.

The collar fits on the flat that the wheel guard attaches to it is a snug fit and has a set screw to secure it which seems to work really well.

The main tube is 3/4" black pipe welded to the collar with a 3/4" rod that slides inside holds the idler wheel a compression spring in the tube below the rod provides tension for the belt by the way crowning the tracking wheel makes a huge difference controlling tracking.

Now for the tracking instead of rocking the idler wheel I took the same approach that my 1 X 42 kalamazoo grinder used and twist the idler wheel to track the belt it means you have to have the belt pretty well lined up to get started but once you get the hang of it it works really well. Once you have the tracking where you want it a 1/4" locking screw keeps it that way I just tapped the black pipe for the screw but you could weld a nut on if you felt you needed more threads.

The whole assembly seems really solid with no vibration at the idler wheel and wow what a difference over grinding wheels.