EdCaffreyMS

"The Montana Bladesmith"

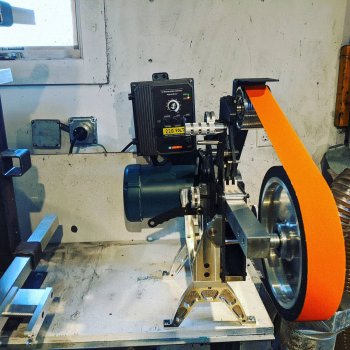

Hey Gang! I just had an almost catastrophic experience.

Last time I applied "glass" to a platen, I remembered reading here on the forums that someone had done it with JB Weld, and decided to give it a try versus using Acragls as a normally do. Didn't work out so well for me! I ground 7 EBKs today, and when I was changing from 50 to 120 grit belts..... the glass literally fell off the platen, and just by reflex I caught it! Had it not been for the little "shelf" that is built into the bottom of my platen face, that glass would have been "sucked" down between the belts, and 3" wheel at the bottom of the platen!!!!

Last time that happened was years ago, and Cindy was picking glass outta my face for a week!

SO......IF YOU HAPPEN TO USE JB WELD TO HOLD GLASS TO A PLATEN FACE.......BEWARE!! Luckily, no injuries, I save the glass, and cleaned up everything, and it's now sitting on the bench, glued on with Acraglas, and waiting to cure.

Last time I applied "glass" to a platen, I remembered reading here on the forums that someone had done it with JB Weld, and decided to give it a try versus using Acragls as a normally do. Didn't work out so well for me! I ground 7 EBKs today, and when I was changing from 50 to 120 grit belts..... the glass literally fell off the platen, and just by reflex I caught it! Had it not been for the little "shelf" that is built into the bottom of my platen face, that glass would have been "sucked" down between the belts, and 3" wheel at the bottom of the platen!!!!

Last time that happened was years ago, and Cindy was picking glass outta my face for a week!

SO......IF YOU HAPPEN TO USE JB WELD TO HOLD GLASS TO A PLATEN FACE.......BEWARE!! Luckily, no injuries, I save the glass, and cleaned up everything, and it's now sitting on the bench, glued on with Acraglas, and waiting to cure.