You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3 phase Disc Sander

- Thread starter Benjy

- Start date

52 Ford

Well-Known Member

Yes.Question, I am seeing some used 3 phase disc sanders around. Can I put a VFD drive on it to make it a variable speed and run on single phase???

Sent from my Champion Forge using Tapatalk

52 Ford

Well-Known Member

Figure out what HP it is. VFDs are advertised by HP and by wattage. There are approximately 750W in 1HP. Buy a VFD rated for a motor larger than you're actually going to be running.

No, that won't hurt the motor. If it's a 1HP 60Hz motor and you drive it at 60Hz, if you're using a 2HP VFD, it's still a 1HP motor. There will just be less stress on the VFD.

Edit: make sure the VFD can accept a 1 phase input. Not all of them can.

I hope this helps!

Sent from my Champion Forge using Tapatalk

No, that won't hurt the motor. If it's a 1HP 60Hz motor and you drive it at 60Hz, if you're using a 2HP VFD, it's still a 1HP motor. There will just be less stress on the VFD.

Edit: make sure the VFD can accept a 1 phase input. Not all of them can.

I hope this helps!

Sent from my Champion Forge using Tapatalk

John Wilson

Well-Known Member

Most VFDs can run on single phase, but it has to be two phases like 220V or 480V (two hots). The KB drive is the only one that I know of that will take single phase 110V and a neutral and put out 220V three phase and they can only pull it off because the biggest they can run is a 2HP if I'm not mistaken. Any VFD that you run on single phase is de-rated. Just like 52 Ford mentions, the solution is to get a VFD that is sized bigger than the motor, and as he said there's no such thing as too big. The rating on a VFD is maximum output. It's a capacity rating, and running it on single phase input drops the capacity by about 30 percent. Don't get wrapped around the axle. Just go one size up at a minimum.

That's the other thing. While motors generally have two options to wire them ( 220V vs 460V/480V), most VFDs do not. Since you are very unlikely to have 480V available, you have to make sure that the VFD you get is a 220V VFD and then make sure the motor you get can be wired 220V to match the output of the VFD.

That's the other thing. While motors generally have two options to wire them ( 220V vs 460V/480V), most VFDs do not. Since you are very unlikely to have 480V available, you have to make sure that the VFD you get is a 220V VFD and then make sure the motor you get can be wired 220V to match the output of the VFD.

CDHumiston

Well-Known Member

Are you trying to run on 110 or 220 single phase?

I have an $80 Chinese VFD on my Disc Sander that works great, but it still used 220 single phase from the wall and converts it to 3 phase for the motor.

I have an $80 Chinese VFD on my Disc Sander that works great, but it still used 220 single phase from the wall and converts it to 3 phase for the motor.

Benjy

Well-Known Member

I have a 50 amp 220 single phase circuit. Sounds like you are doing what i want to doAre you trying to run on 110 or 220 single phase?

I have an $80 Chinese VFD on my Disc Sander that works great, but it still used 220 single phase from the wall and converts it to 3 phase for the motor.

jmforge

Well-Known Member

Eventually, I want to put an A/B swith on the VFD for my KMG and run a disc. I have had a Nathan 1 degree disc for years, but I have never used it. My KMG runs on 110 so the motor is a 1.5 hp. Could I run a 1 hp on that same VFD? I also want to install the reverse switch on the VFD which I have put off for like 6 years. LOL

John Wilson

Well-Known Member

You can do an A/B switch, or more cost effectively, use Dryer plugs if the disc grinder is close to your belt grinder so that you can reach the VFD. Wire a pigtail with a male dryer plug on each of your grinders. Wire a pigtail on the VFD output with a female dryer plug. Then all you have to do is plug in whichever grinder you want to run.Eventually, I want to put an A/B swith on the VFD for my KMG and run a disc. I have had a Nathan 1 degree disc for years, but I have never used it. My KMG runs on 110 so the motor is a 1.5 hp. Could I run a 1 hp on that same VFD? I also want to install the reverse switch on the VFD which I have put off for like 6 years. LOL

Yes, you can run a 1HP motor off your 1.5HP VFD. The VFD can always be a larger rating than the motor. For VFDs, the HP rating the max capacity it can output. They don't have to match the motor.

jmforge

Well-Known Member

Thanks. This VFD is supposedly 1.5hp at 110 and 2 hp at 220.You can do an A/B switch, or more cost effectively, use Dryer plugs if the disc grinder is close to your belt grinder so that you can reach the VFD. Wire a pigtail with a male dryer plug on each of your grinders. Wire a pigtail on the VFD output with a female dryer plug. Then all you have to do is plug in whichever grinder you want to run.

Yes, you can run a 1HP motor off your 1.5HP VFD. The VFD can always be a larger rating than the motor. For VFDs, the HP rating the max capacity it can output. They don't have to match the motor.

CDHumiston

Well-Known Member

I have a 50 amp 220 single phase circuit. Sounds like you are doing what i want to do

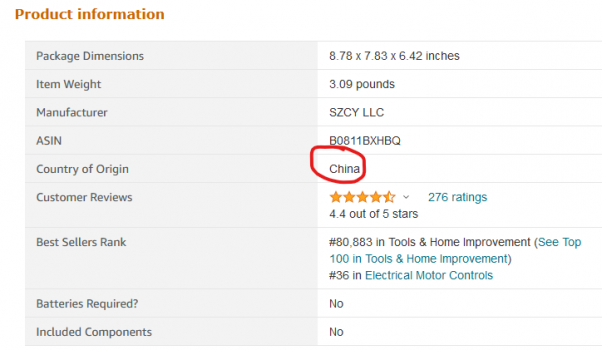

This is what I bought, and it works great. Price has increased $8 since my purchase...

52 Ford

Well-Known Member

If the 3 phase motor doesn't work out well, you can always put a gas engine on it.Thanks everyone, great information!!!

Sent from my Champion Forge using Tapatalk

52 Ford

Well-Known Member

@CDHumiston

You laugh...

I wasn't happy with the electric motor on my bandsaw. Wanted something bigger and variable speed.

*Enter Honda*

I ended up with a 5.5HP Honda powering my vertical bandsaw.

Even idling it had PLENTY of power. Plus, I used the vibration from the engine to my advantage. I have a 2" dust extraction port at the bottom of the saw and I had the engine shaking a 2" pipe so the sawdust would travel down it and end up in a pile outside the shop. I was running some blades that I custom ground. They started life as 6 TPI raker blades, but they ended up more like a combination blade for a table saw. With large "hook" gullets every inch or so and small rakers between. Worked GREAT for what I was doing at the time... I started doing less and less woodworking. Eventually, I was just cutting up firewood with it.

I actually took that engine off a couple days ago to give to a neighbor. He needed a motor for his pressure washer and this was a perfect fit. Traded him Tecumseh for my tiller.

Haven't used it in 2 years.

Once I get the expansion on the back of the shop and all the metal working equipment set up, I'll get my woodworking stuff back on par.

Edit, my next two grinders (the BIG belt grinder and another "normal" one) are going to be driven off of a lineshaft with a gas engine.

You laugh...

I wasn't happy with the electric motor on my bandsaw. Wanted something bigger and variable speed.

*Enter Honda*

I ended up with a 5.5HP Honda powering my vertical bandsaw.

Even idling it had PLENTY of power. Plus, I used the vibration from the engine to my advantage. I have a 2" dust extraction port at the bottom of the saw and I had the engine shaking a 2" pipe so the sawdust would travel down it and end up in a pile outside the shop. I was running some blades that I custom ground. They started life as 6 TPI raker blades, but they ended up more like a combination blade for a table saw. With large "hook" gullets every inch or so and small rakers between. Worked GREAT for what I was doing at the time... I started doing less and less woodworking. Eventually, I was just cutting up firewood with it.

I actually took that engine off a couple days ago to give to a neighbor. He needed a motor for his pressure washer and this was a perfect fit. Traded him Tecumseh for my tiller.

Haven't used it in 2 years.

Once I get the expansion on the back of the shop and all the metal working equipment set up, I'll get my woodworking stuff back on par.

Edit, my next two grinders (the BIG belt grinder and another "normal" one) are going to be driven off of a lineshaft with a gas engine.

MTBob

Well-Known Member

Two things: 1) even with a filter built in, this unit may not be suitable for dirty / gritty applications, 2) It's made in China.This is what I bought, and it works great. Price has increased $8 since my purchase...

https://www.amazon.com/SZCY-LLC-220...vfd&qid=1651622526&sprefix=vfd,aps,135&sr=8-5

CDHumiston

Well-Known Member

Two things: 1) even with a filter built in, this unit may not be suitable for dirty / gritty applications, 2) It's made in China.

View attachment 80748

Understood, but it was cheap and so far it works great! If your shop gets really dirty you can always build an enclosure for it.

I do not boycott Chinese products. They are putting out some decent quality stuff and politics doesn't decide my purchases.

MTBob

Well-Known Member

Fair enough, I respect your decision. When possible, if there isn't too big a price difference, I'm inclined to "vote" with my wallet.Understood, but it was cheap and so far it works great! If your shop gets really dirty you can always build an enclosure for it.

I do not boycott Chinese products. They are putting out some decent quality stuff and politics doesn't decide my purchases.

CDHumiston

Well-Known Member

Fair enough, I respect your decision. When possible, if there isn't too big a price difference, I'm inclined to "vote" with my wallet.

I will try and buy USA made products if the price is reasonable and the quality is good.

Made in the USA doesn't stand up like it used to and many "USA" companies have opened factories outside the USA.

Many companies also import the entire product here in pieces and the assemble it here to claim, "Made in the USA".

It's all about the profit and feeding the shareholders...unfortunate for sure.

MTBob

Well-Known Member

Points well taken. Reminds me of traveling in Asia and visiting a Wrangler garmet factory. The pants were made with Chinese labor. They manufacured the entire garmet except for sewing the label on. The pants were then sent to the US where "Made In USA" label was sewen on and then considered to be a US product . And, evidently that was (is?) legal.

Andre Grobler

Well-Known Member

There are some 3phase motors that are not suitable for vfd,it hasto do with the grounding, which can spark arc throughthe bearings, damaging them over time. Not sure if this is a problem with current production motors, and could never find outhow totell