You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3/32" Tool Steel - My Mistake

- Thread starter opaul

- Start date

opaul

Well-Known Member

Thanks Rick.I know a few guys who use 3/16 I guess it's wat you prefer! Nice blade OP!

It's a little thin for me to use regularly but since I had a few bars of it lying around, I decided to use it. One thing about 01 is that it takes a wicked, wicked edge.

Von Gruff

KNIFE MAKER

3/16 will make up into a heavier knife and many like the heft of a knife like that. I use a near 3/16 1070 (11/64 or .170) for my pig stickers.

My O1 for the bushcraft hunter is .156 so more like 5/32 but that is plenty of stout for what they are intended for. The same for the 1095 fighter but everything else is 1/8 or down to the 3/32 for the 15N20

My O1 for the bushcraft hunter is .156 so more like 5/32 but that is plenty of stout for what they are intended for. The same for the 1095 fighter but everything else is 1/8 or down to the 3/32 for the 15N20

Smallshop

KNIFE MAKER

A few years back I was doing only O-1 and new to heat treating...I learned a couple things from scott.livesey practically/philosophically that I still try to apply with O-1 and With A2(which I now predominately use)....the first is...most knives that are slicers are WAY TOO THICK. I've made a skinning knife from 1/16 O-1 that guys rave about.

I know that Scott makes some out of 1/32 for kitchen work...I'm betting that his will cut sushi with the best of 'em. Because my little cowboy knife needs to stand up to SOME abuse I made it 1/8 thick. That's thick enough as it is a small blade...as I make longer blades I will scale up accordingly. Fighters and pig stickers obviously need to be a bit thicker.

Until you make and use a thin knife you will not know what a delight they are...and how well they hold up.

The second is....O-1 does not get tougher as you lower the hardness. Don't fall prey to the notion that 58-57 gonna work well...it won't. Best to keep it at RC 60-61. My 1/16 skinner (...i loan it out for feedback and the professional coyote hunter that has it now keeps forgetting to return it...) flexes like a boning knife (almost...a bit stiffer) and stays sharp through an entire deer. O-1 has it's best toughness up near it's best edge holding hardness...sweet!...search scott.livesey in the HT forum for a great O-1 recipe...It's what I use and I just love how easy O-1 is to sharpen at the correct hardness.(scott really know O-1 well...worth seeing what he says about it).

I switched to A2 for it's ability to resist rust a bit better..and that is noticible....but I'm not sure toughness and edge holding is THAT much better than O-1. I do have a bit harder time sharpening A2 than O-1...In short though...I LOVE tool steel for blades.

I know that Scott makes some out of 1/32 for kitchen work...I'm betting that his will cut sushi with the best of 'em. Because my little cowboy knife needs to stand up to SOME abuse I made it 1/8 thick. That's thick enough as it is a small blade...as I make longer blades I will scale up accordingly. Fighters and pig stickers obviously need to be a bit thicker.

Until you make and use a thin knife you will not know what a delight they are...and how well they hold up.

The second is....O-1 does not get tougher as you lower the hardness. Don't fall prey to the notion that 58-57 gonna work well...it won't. Best to keep it at RC 60-61. My 1/16 skinner (...i loan it out for feedback and the professional coyote hunter that has it now keeps forgetting to return it...) flexes like a boning knife (almost...a bit stiffer) and stays sharp through an entire deer. O-1 has it's best toughness up near it's best edge holding hardness...sweet!...search scott.livesey in the HT forum for a great O-1 recipe...It's what I use and I just love how easy O-1 is to sharpen at the correct hardness.(scott really know O-1 well...worth seeing what he says about it).

I switched to A2 for it's ability to resist rust a bit better..and that is noticible....but I'm not sure toughness and edge holding is THAT much better than O-1. I do have a bit harder time sharpening A2 than O-1...In short though...I LOVE tool steel for blades.

opaul

Well-Known Member

You read it right the first time! I edited to correct my errorI just re-read the title and realised that I had read it as 3/16 rather than 3/32 which explains why my previous post may not have been as relevant as I had intended when I typed it out.

Chris Railey

Well-Known Member

Ted, I use O-1 a lot for blades but I have never gone below 1/8 thick. How are the thinner O-1 blades about warping during HT?

Smallshop

KNIFE MAKER

I've only done as thin as 1/16...they came out flat...they cool very quick...lol.Ted, I use O-1 a lot for blades but I have never gone below 1/8 thick. How are the thinner O-1 blades about warping during HT?

i did not plate quench...and i grind after heat treat...lot less metal to remove...grinds quick.

Gliden07

Well-Known Member

I just re-read the title and realised that I had read it as 3/16 rather than 3/32 which explains why my previous post may not have been as relevant as I had intended when I typed it out.

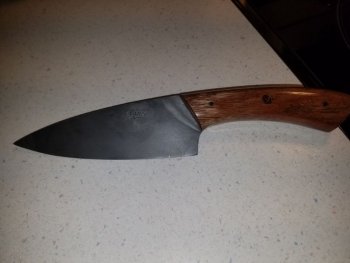

I did a chef's knife in 3/32" O1 what I did was profile blade, heat treat then grind bevels. No problems with it. Here's a not good pic but a pic just the same.

Attachments

Nick Riggi

Well-Known Member

Chris Railey

Well-Known Member

I do not have a way to accurately check the hardness but I am very happy with the performance I get with O-1 that is why I asked about thinner stock I think it should take an excellent edge. Grinding after heat treat for thinner stock makes sense I think that should minimize warps. I am going to order some thinner or maybe just thin some of the 1/8th I have. It will give me a chance to try out my new digital calipers.Chris have you noticed how nice they perform at 60rc and above?

Smallshop

KNIFE MAKER

Nice knife 07!I did a chef's knife in 3/32" O1 what I did was profile blade, heat treat then grind bevels. No problems with it. Here's a not good pic but a pic just the same.