Fellhoelter

Well-Known Member

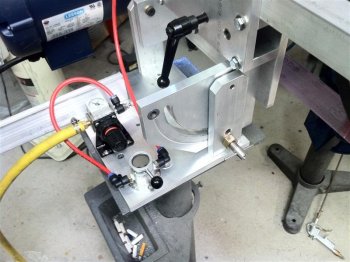

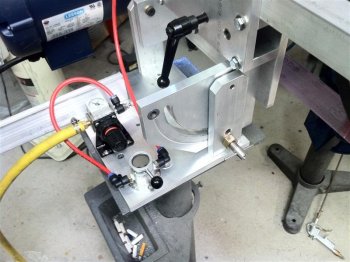

Is it a vertical grinder?

A horizontal grinder?

Pneumatically sprung with variable tension?

3hp?

Yes, yes it is.

I have had this one on the drawing boards for a couple of years now.

Finally decided to go for it.

It rotates from vertical to horizontal by pulling 1 spring detent pin, and locks in place well.

There's also a quick adjust handle to lock it in place if I want to, with just a fraction of a turn.

This will make it a dedicated vertical or horizontal machine

It's built so it can use pneumatics, or a standard gas spring if I don't like the pneumatics.

Belt tension can go from really light, to "I hope I don't break the belt" with a twist of the dial on the regulator.

Flow controls ease it tight, then loose, so no slamming open and closed.

Beaumont rubber drive and tracking wheels, uses all my KMG attachments.

I other words, all off the shelf attachments.

Second receiver for the fancy tool rest system I have in the Werks.

VFD has moved from these pics, and a light has been mounted.

A mist unit can easily be bolted up, or I'll epoxy a piece of steel on the tension arm and use a magnetic base misting unit.

I'm calling it the Übergrinder.

.

.

A horizontal grinder?

Pneumatically sprung with variable tension?

3hp?

Yes, yes it is.

I have had this one on the drawing boards for a couple of years now.

Finally decided to go for it.

It rotates from vertical to horizontal by pulling 1 spring detent pin, and locks in place well.

There's also a quick adjust handle to lock it in place if I want to, with just a fraction of a turn.

This will make it a dedicated vertical or horizontal machine

It's built so it can use pneumatics, or a standard gas spring if I don't like the pneumatics.

Belt tension can go from really light, to "I hope I don't break the belt" with a twist of the dial on the regulator.

Flow controls ease it tight, then loose, so no slamming open and closed.

Beaumont rubber drive and tracking wheels, uses all my KMG attachments.

I other words, all off the shelf attachments.

Second receiver for the fancy tool rest system I have in the Werks.

VFD has moved from these pics, and a light has been mounted.

A mist unit can easily be bolted up, or I'll epoxy a piece of steel on the tension arm and use a magnetic base misting unit.

I'm calling it the Übergrinder.

.

.

Last edited: