I grind all freehand, so this advice might not apply if you're using a jig.

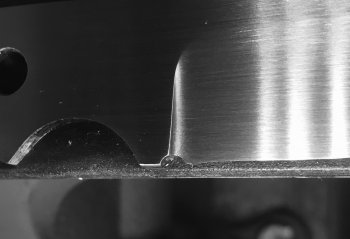

Personally, When I start grinding a blade, the plunges are always "set" a fraction of an inch further forward than where I want them to end up. I then grind the blade, and the LAST thing I do is to run the edge of the belt past the edge of the platen, then, A LITTLE AT A TIME, I "walk" the plunge to it's finish location.... changing sides as I go. I ALWAYS do this with a J-weight belt....because it will "roll" over the edge of the platen, and give the bottom of my plunge cuts a nice radius (which I like much better than square cuts).

I don't pay much attention to where plunges are during rough grinding (pre heat treat), as long as they are FORWARD of where I want them in the finished blade. After heat treating, I finish grind the blade, then then treat the plunges as described above.