Methow packer

Member

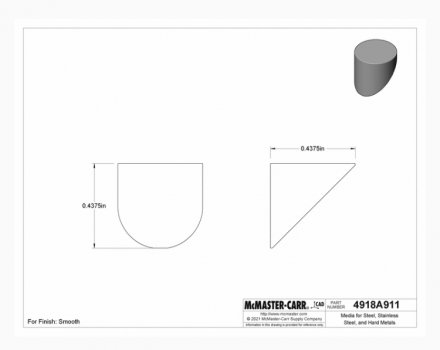

I’ve tried stone washing my tempered blades using ceramic triangular media ( from Harbor freight) in some soapy water. I’m using a larger vibrater. I’m not getting the results I would have hoped. Sure there is some texture there but not enough for me. I even vibrate over night. The results are minimal. I know this S35 steel is somewhere @ 60-61 R. Can someone in the know help me with what might be a better procedure and media that they have been successful with?