You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My current problem

- Thread starter Jesse Latham

- Start date

opaul

Well-Known Member

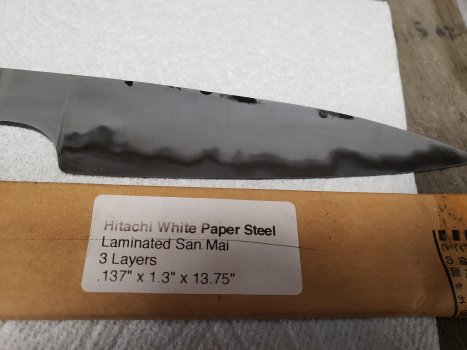

Can you tell us a little more about it? What steel's were used. I do a lot of grinding post heat treat and I haven't had that particular problem. The blade thickness is over 1/8" so if it was tempered at 400 degrees I wouldn't think there would be much flexibility.Has anyone used this san mai? The outer layers are mild steel I think. I followed the heat treat temps and the edge seems hard but I can bend the blade by hand. I did grind post heat treat. Maybe that's the issue.

Jesse Latham

Well-Known Member

This is 3 layers. Mild steel outside with a white paper steel core. .105 thick as heat treated. The edge didn't chip or roll with a brass rod. I did some more digging and found the suggestion it needs ground before heat treat. I've ground the edge back and heading back to the oven.

Attachments

Remember, mild steel doesn't really get hard, even with water quench. All you're looking at is the thin center section to harden and resist bending. I've made a couple of mild steel clad blades (<.100") with 1080 or 1095 center and after hardening, the blade will bend and take a set fairly easy. Also easy to straighten back out after quenching and tempering. How easy depends on thickness of cladding and center core. Seems to me there is always the danger of the core cracking when bending.

Jesse Latham

Well-Known Member

That was kind of what I was thinking. It sucks though. Totally not a product I could put forth to a customer. And I have several pieces. It's in the temper oven so we'll see if it changes.

EdCaffreyMS

"The Montana Bladesmith"

My suspicion is that the finished material was compromised through the creation process. I've always been somewhat suspicious of any commercially available/manufactured Damascus and/or laminated steels. Why? First, whomever produces it, are always super secretive about the process..... telling only enough to make less knowledgeable people go... "Ohhhhh!" "Ahhhh!", but always leaving portions of the process to speculation. Where as some would get sucked in by that..... for me, it throws up a red flag for me.

Next, you don't do this as long as I have, and not have some "inside" tracks. And some of mine have enlightened me that this specific material is simply not "up to snuff", due to the process use to make it. Remember how I'm always talking about the "give-n-take" we deal with in knifemaking? In this case, according to my sources, it would seem that in order to be profitable in making/selling this particular material, certain "shortcuts" were/are taken that leaves the finished product in a less then desirable state for blades. In other words, to put it plainly, this is one of those materials that is all show, and no go. Depending instead, on the "Wow Factor" to have people buy and use it.

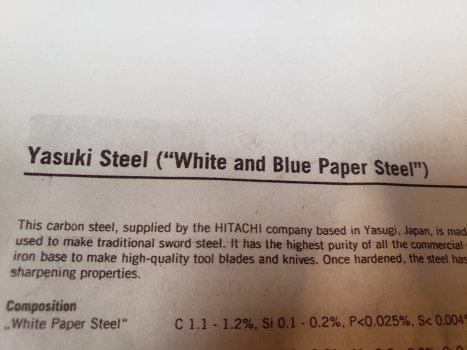

All that being said, I have personally used, or more accurately, TRIED to use this material to produce blades. After going through several pieces, all with the same, and similar results to you (Jesse), my conclusion is just what I said earlier..... all show, no go. The core is (the "white paper 2" steel) is plain as plain carbon steel gets..... in the 1% carbon area, with .25% manganese, and usually a trace of Silicon. Coring that with mild steel laminates isn't a bright idea to begin with, especially with such a thin core, there isn't going to be much strength there if laminated under ideal conditions. Factor in taking "shortcuts" when laminating it to maintain profitability.....These days, there is a TON of that kind of stuff out there, and it is certainly a "buyer beware" jungle.

Next, you don't do this as long as I have, and not have some "inside" tracks. And some of mine have enlightened me that this specific material is simply not "up to snuff", due to the process use to make it. Remember how I'm always talking about the "give-n-take" we deal with in knifemaking? In this case, according to my sources, it would seem that in order to be profitable in making/selling this particular material, certain "shortcuts" were/are taken that leaves the finished product in a less then desirable state for blades. In other words, to put it plainly, this is one of those materials that is all show, and no go. Depending instead, on the "Wow Factor" to have people buy and use it.

All that being said, I have personally used, or more accurately, TRIED to use this material to produce blades. After going through several pieces, all with the same, and similar results to you (Jesse), my conclusion is just what I said earlier..... all show, no go. The core is (the "white paper 2" steel) is plain as plain carbon steel gets..... in the 1% carbon area, with .25% manganese, and usually a trace of Silicon. Coring that with mild steel laminates isn't a bright idea to begin with, especially with such a thin core, there isn't going to be much strength there if laminated under ideal conditions. Factor in taking "shortcuts" when laminating it to maintain profitability.....These days, there is a TON of that kind of stuff out there, and it is certainly a "buyer beware" jungle.

Jesse Latham

Well-Known Member

Thanks all for the replies. While it isn't the first crappy thing I've bought it doesn't make me happy. Live and learn.

Jesse Latham

Well-Known Member

After heat treat as ground the blade is still bendable. No surprise. I broke it in the vise. It snapped like you expect. The surprising thing is I sharpened the remaining 1/3 of the blade and it holds a good edge. Nothing I could sell. But after beating a piece of walnut it still shaved hair.

Greg Rice

Well-Known Member

Thank you @Jesse Latham for taking one for the team. Doesn’t make it any better for you - but glad to learn this tonight.

1Zach1

Active Member

I'm honestly so very confused. Everything I have ever read about Hitachi steels is how high quality they are and how on point their manufacturing is. White steel is extremely sought after, probably right after Super Blue, when it comes to kitchen steels and prominently used in high end Japanese knives. So what gives? Bad batch? Over hype? Just more difficult to work with?

Jesse Latham

Well-Known Member

I'm unable to answer that. For me giving a product guarantee is good but not good enough. My expectation is not to have any come backs and I will do anything I can to make that happen. Including pitching $$ of steel in the trash. I did a short vid for a blacksmith guild of me bending the knife over my knee. I gave remaining 7 inches of the knife about a 1.5 inch curve.So what gives?