Daniel Macina

Well-Known Member

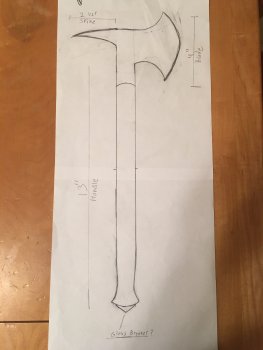

Evening Gents!

I was wondering what Y’alls thoughts on this this tomahawk/hatchet is and any thoughts on improvements?

As much as I hate the term “tactical” I kind of went for a tactical look on this one. I have plans for a much nicer more involved version of this but I’ll keep that under wraps for now. This is just going to be bare bones to see how it looks and feels. Not sure I’ll keep the glass breaker I was just seeing what the reaction to it is.

total length: 16”

handle length 13”

blade length 4”

Spike length 2”

tip of spike to blade 6”

handle width 1 1/4th”

Apologies for my bad drawing.

normally not my kind of thing but I’ve had this stuck in my head for some reason.

I was wondering what Y’alls thoughts on this this tomahawk/hatchet is and any thoughts on improvements?

As much as I hate the term “tactical” I kind of went for a tactical look on this one. I have plans for a much nicer more involved version of this but I’ll keep that under wraps for now. This is just going to be bare bones to see how it looks and feels. Not sure I’ll keep the glass breaker I was just seeing what the reaction to it is.

total length: 16”

handle length 13”

blade length 4”

Spike length 2”

tip of spike to blade 6”

handle width 1 1/4th”

Apologies for my bad drawing.

normally not my kind of thing but I’ve had this stuck in my head for some reason.