You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Broach

- Thread starter Gliden07

- Start date

Looks mean. I made one similar to that out of a Sawzall blade that cuts pretty aggressively.

Although I haven't thought it through yet, sometime I want to make a narrow chisel to help digging out a cavity for full tangs. I want to try cutting down into the material instead of only being able to pull material out. AKWildman showed them on a video he did, but I can't remember what thread it was on.

Although I haven't thought it through yet, sometime I want to make a narrow chisel to help digging out a cavity for full tangs. I want to try cutting down into the material instead of only being able to pull material out. AKWildman showed them on a video he did, but I can't remember what thread it was on.

Gliden07

Well-Known Member

Looks mean. I made one similar to that out of a Sawzall blade that cuts pretty aggressively.

Although I haven't thought it through yet, sometime I want to make a narrow chisel to help digging out a cavity for full tangs. I want to try cutting down into the material instead of only being able to pull material out. AKWildman showed them on a video he did, but I can't remember what thread it was on.

I thought the same thing!. I looked on Amazon and found some 1/8" wood chisels. Also thought a Mortising bit but the smallest one I found was 1/4" (makes sense). I know everyone gets the bits in and then slides them sideways to connect the holes. In stabilized woods I've had problems doing that broken bits, chuck falling off drill press and the hole never comes out very good.

Gliden07

Well-Known Member

Looks good. I did the same with a saws all blade. It works great. I got the idea from Gruff awhile back.

I tried doing this and I always ended up with a bump in the middle of the hole that was difficult to remove (because blades were so thin). Maybe a combination of that and chisel would work??

Jesse Latham

Well-Known Member

Solder 2 blades together to make it wider.

EdCaffreyMS

"The Montana Bladesmith"

I have several of these type handle broaches in the shop....each is made slightly differently. Here are my two favorites...

The first one is made my ABS Mastersmith Johnny Perry. Very nice broach, and cuts amazingly on almost any material.

Teeth are straight on this one.....

I also really like my Damascus one... I tend to use it on the majority of Hunter sized hidden tangs I make..... I think it needs sharpened....I've used the heck out of it.

I've found that straight teeth in a broach work best in most woods, as the teeth do not clog as much as a broach with off-set teeth.

Where the Off-Set teeth really shine is on harder materials. NOTE: I do not recommend using handle broaches on G10, Micarta, and NEVER on carbon fiber. The first two will dull the broach quickly.....and carbon fiber will flat out destroy it.

The first one is made my ABS Mastersmith Johnny Perry. Very nice broach, and cuts amazingly on almost any material.

Teeth are straight on this one.....

I also really like my Damascus one... I tend to use it on the majority of Hunter sized hidden tangs I make..... I think it needs sharpened....I've used the heck out of it.

I've found that straight teeth in a broach work best in most woods, as the teeth do not clog as much as a broach with off-set teeth.

Where the Off-Set teeth really shine is on harder materials. NOTE: I do not recommend using handle broaches on G10, Micarta, and NEVER on carbon fiber. The first two will dull the broach quickly.....and carbon fiber will flat out destroy it.

Last edited:

opaul

Well-Known Member

Nice! Would love a set like that. Hint hint.I have several of these type handle broaches in the shop....each is made slightly differently. Here are my two favorites...

The first one is made my ABS Mastersmith Johnny Perry. Very nice broach, and cuts amazingly on almost any material.

Teeth are straight on this one.....

I also really like my Damascus one... I tend to use it on the majority of Hunter sized hidden tangs I make..... I think it needs sharpened....I've used the heck out of it.

I've found that straight teeth in a broach work best in most woods, as the teeth do not clog as much as a broach with off-set teeth.

Where the Off-Set teeth really shine is on harder materials. NOTE: I do not recommend using handle broaches on G10, Micarta, and NEVER on carbon fiber. The first two will dull the broach quickly.....and carbon fiber will flat out destroy it.

me too - on mine I utilized the hook, the last tooth on the end of the sawzall blade - I think I got that from him too. I don't really remember its been awhile and I've been crazy busy.I got the idea from Gruff awhile back.

A sawzall blade seems like a good choice as a repurposed steel, though - they're probably made for wear resistance. I like the flexibility too, but sometimes I'm not sure if I'd get a cleaner hole if I made a thicker broach.

EdCaffreyMS

"The Montana Bladesmith"

I was just thinking back to my early years..... the first FEW broaches I made were from sawzall blades..... the best ones were 3-4 sawzall blades of the same style/type stacked and spot welded together. A spot weld is great for this because the heat affected zone is so tiny, the teeth are not affected.

tkroenlein

Well-Known Member

I suppose I'll just bump up this thread instead of starting a new one.

Anybody got any advice or patterns for laying out the teeth on these? I'm going to make one in the 1/8" wide range.

Anybody got any advice or patterns for laying out the teeth on these? I'm going to make one in the 1/8" wide range.

J. Doyle

Dealer - Purveyor

I suppose I'll just bump up this thread instead of starting a new one.

Anybody got any advice or patterns for laying out the teeth on these? I'm going to make one in the 1/8" wide range.

Yeah....use a Sawzall blade and grind it to shape, leaving about 4 teeth on it. The thickest Milwaukee blade you can find....I think it's named the ax. Its quite thick, right around 1/8". Its the first one I made 10+ years ago and its still going strong.

I'm all for quality tools but a broach isn't a place where a guy needs to spend a bunch of time and money. I can broach very precise square sided holes in minutes with mine.

tkroenlein

Well-Known Member

That would be their wood blade rated for nails/demo work with a relatively low tooth count. Reckon I can give that a shot. I actually have a single tooth one I ground out of a small chicom file that works...it just keeps bending on me.Yeah....use a Sawzall blade and grind it to shape, leaving about 4 teeth on it. The thickest Milwaukee blade you can find....I think it's named the ax. Its quite thick, right around 1/8". Its the first one I made 10+ years ago and its still going strong.

I'm all for quality tools but a broach isn't a place where a guy needs to spend a bunch of time and money. I can broach very precise square sided holes in minutes with mine.

Bruce McLeish

Well-Known Member

If you're going to make one, just take some scrap hi carbon steel, shape it , harden it and, voila.....broach!!!

MTBob

Well-Known Member

EdCaffreyMS

"The Montana Bladesmith"

I made my own for some time, but I gotta tell ya, after using the ones that Johnny Perry, MS makes, there isn't any point. It's worth twice the money I paid for it, and as long as he's offering them.... I'm not even gona waste the time trying anymore.

tkroenlein

Well-Known Member

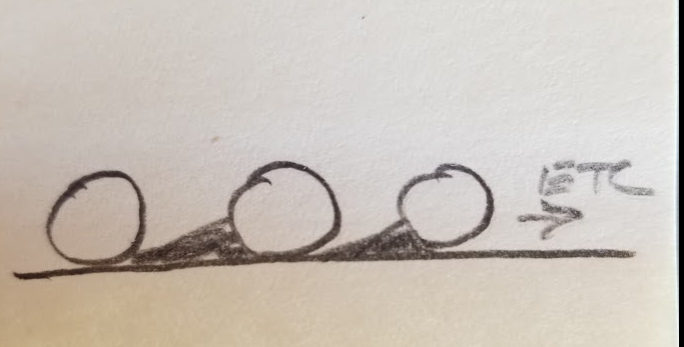

I have seen some done like that, and it looks like a pretty "easy" way to make a tooth.You might consider drilling a series of holes and carefully grind out the relief, as shown in the ultra-fancy post-it-note sketch. And, as Bruce mentioned, using a piece of heat treatable steel.

View attachment 77753

Gliden07

Well-Known Member

I made my own for some time, but I gotta tell ya, after using the ones that Johnny Perry, MS makes, there isn't any point. It's worth twice the money I paid for it, and as long as he's offering them.... I'm not even gona waste the time trying anymore.

I bought one from Jordan Lamothe. It's more to hog ot the side though. Works GREAT!!