Calvin Robinson

Moderator Christian Forum

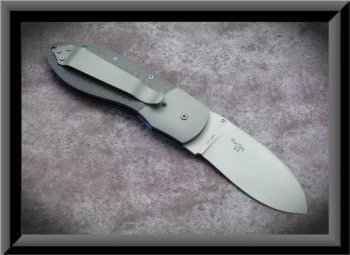

I made these dies today so that I can form my own pocket clips. I borrowed my friends,Steve Jernigan's,dies that he made years ago and copied them so I could have my own set. The first two photos show the dies with dowel pins for alignment.

The third photo shows cutting the .038" titanium close to the lines I scribed from my pattern. The fourth photo shows 4 rough cut pocket clips and the 5th photo shows me grinding to my scribed lines.

The third photo shows cutting the .038" titanium close to the lines I scribed from my pattern. The fourth photo shows 4 rough cut pocket clips and the 5th photo shows me grinding to my scribed lines.