Diamond G Knives

Well-Known Member

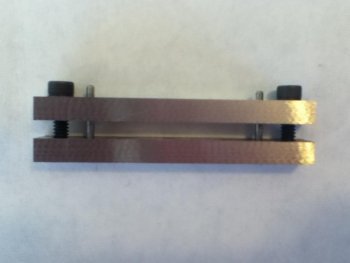

Just wondering if anyone had used a carbide faced filing guide? Its my understanding that it allows use in the grinder.

http://www.riversidemachine.net/item576493.ctlg

Here is a link to the ne I was looking at.

Thanks and God Bless

Mike

http://www.riversidemachine.net/item576493.ctlg

Here is a link to the ne I was looking at.

Thanks and God Bless

Mike