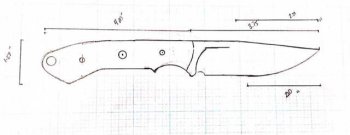

OK, Ive got my "shop space" set up, with a few power tools, and some hand tools (4x36 HF belt grinder, drill press, cheap band saw). I've played around with some handles (couple of premade knife blanks, basic kitchen style knives) and I'm wanting to move up to actually making something "for real"  ...

...

So my question involves metal. What is the "best" for the first knife? Most of what I read seemed to point to 1084, but I have no way to heat treat it (Im in a "borrowed" space, and the owner isnt keen on fire and stuff ) so I'd have to send it out... now, I'm local to Texas Knife Supply, and they heat treat, but they ONLY do Air Quench metals... so that leads me to 440c. So, whats the best option? any thoughts and/or suggestions are much appreciated

) so I'd have to send it out... now, I'm local to Texas Knife Supply, and they heat treat, but they ONLY do Air Quench metals... so that leads me to 440c. So, whats the best option? any thoughts and/or suggestions are much appreciated

So my question involves metal. What is the "best" for the first knife? Most of what I read seemed to point to 1084, but I have no way to heat treat it (Im in a "borrowed" space, and the owner isnt keen on fire and stuff