Chris Railey

Well-Known Member

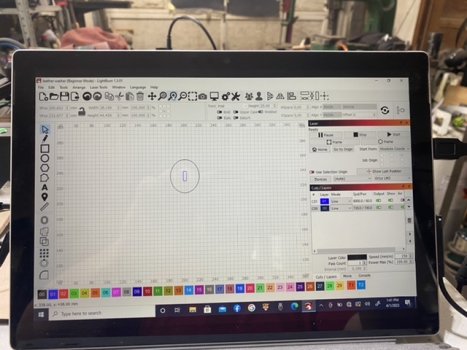

I wanted to see if you guys are interested in me posting some knife (making) specific testing on the Laser cutter I recently acquired. It is a 10W diode laser (Ortur Laser Master 3) and I familiar enough with its operation now to do some pretty in depth testing related to knife stuff. I will post in WIP style if there is interest. The engraver is supposed to be able to engrave Stainless and HC steel with no chemicals (have not tested that yet). Post up if you want to see results.

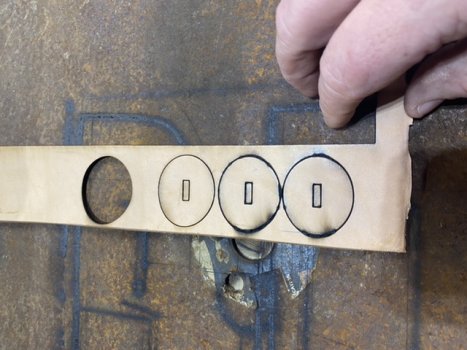

I can already tell you that I will never cut another sheath blank by hand. I am fortunate enough to have taught myself previously how to use QCAD so I drew out a sheath blank and was able to cut it straight away. One pass and three minutes from start to finish including the laser cut welt. Glued it together and sewed it up without ANY trimming or fitting. I may cry... I have a CowBoy Outlaw machine so I did not cut stitching holes but the laser will cut 1mm (.039) holes perfectly, so no more stitching chisels. I am also going to draw out some upside down teardrop shaped leather washer files complete with tang cutout for a current project I am working on which is a Twisted Damascus KA-Bar for a retiring friend.

I can already tell you that I will never cut another sheath blank by hand. I am fortunate enough to have taught myself previously how to use QCAD so I drew out a sheath blank and was able to cut it straight away. One pass and three minutes from start to finish including the laser cut welt. Glued it together and sewed it up without ANY trimming or fitting. I may cry... I have a CowBoy Outlaw machine so I did not cut stitching holes but the laser will cut 1mm (.039) holes perfectly, so no more stitching chisels. I am also going to draw out some upside down teardrop shaped leather washer files complete with tang cutout for a current project I am working on which is a Twisted Damascus KA-Bar for a retiring friend.