You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

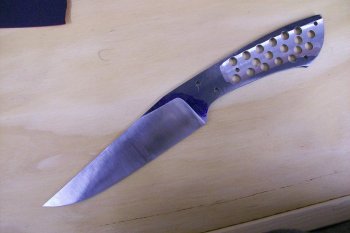

Elmax Build n Test n Show Thread

- Thread starter BossDog

- Start date

Frank Niro

KNIFE MAKER

Yes a great shape Shahan !!

G. Shahan

Well-Known Member

Pieter

Well-Known Member

That's a really sleek,slick looking knife,

lookin' forward to seeing her finished!

Me too can't wait to see it.

G. Shahan

Well-Known Member

Okie dokie,

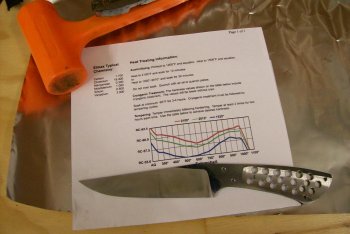

Out of the super duper hillbilly cryo tank. Two hours twice at 400 F. Back to the grinder to take the bevels a little higher and thinner.

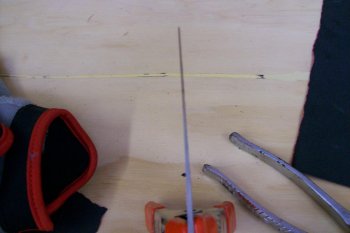

Next to taper the tang, I use a 50 grit blaze and run it as fast as my grinder will run, then a new 120 at a slower speed.

I am making this one super thin.

Next to the granit surface plat to make every thing flat. Then hand sand.

Hand sanding is a little tough.

As an added note, please dont sand with your tip hanging over the end of your jig like this!!!

Out of the super duper hillbilly cryo tank. Two hours twice at 400 F. Back to the grinder to take the bevels a little higher and thinner.

Next to taper the tang, I use a 50 grit blaze and run it as fast as my grinder will run, then a new 120 at a slower speed.

I am making this one super thin.

Next to the granit surface plat to make every thing flat. Then hand sand.

Hand sanding is a little tough.

As an added note, please dont sand with your tip hanging over the end of your jig like this!!!

Carey Quinn

KNIFE MAKER

Looks like you have a nice knife going there. I'm quite interested in this elmax steel and look forward to the results that you and the other testers get with it. It looks like it could be a great performer for the stock remover.

I really need to start doing tapered tangs. If you don't mind my asking, what size wheel are you using for the hollow grind on the taper?

Thanks,

Carey

I really need to start doing tapered tangs. If you don't mind my asking, what size wheel are you using for the hollow grind on the taper?

Thanks,

Carey

G. Shahan

Well-Known Member

Thanks for the comments fells,

Carey,

I use a two inch wheel, at the wide part of the tang I move the grind up and down to be about 3/16 from the edges.

So far this steel is pretty much straight forward to work with.

After heat treat its TOUGH to grind and VERY TOUGH to hand sand.

It took twice the sand paper and twice the time that 1080,1084, or

1095 takes.

It looks really good at 400 grit though.

Greg

Carey,

I use a two inch wheel, at the wide part of the tang I move the grind up and down to be about 3/16 from the edges.

So far this steel is pretty much straight forward to work with.

After heat treat its TOUGH to grind and VERY TOUGH to hand sand.

It took twice the sand paper and twice the time that 1080,1084, or

1095 takes.

It looks really good at 400 grit though.

Greg

Carey Quinn

KNIFE MAKER

Thanks Greg, I've got a 3" so I'll give that a try.

Carey

Carey

G. Shahan

Well-Known Member

Well my wife took off with my camera and left it at a friends house so I dont have pics.

I tested my Elmax knife a few days ago and am impressed.

Chopped 2x4's, chopped tree branches, then sliced up three cardboard boxes.

Still shaving sharp at this point. Chopped more 2x4's, chopped more tree limbs.

Shaved curls off of plywood, cut more cardboard.

Chopped 1/8 inch brass rod with the help of a mallet, shaved brass rod.

Sabbed the point as deep into a 2x4 as I could, then bent side ways to try to break it off.

I did this about a hundred times, almost dug a hole through the board.

Tip showes no damage at all.

Knife is not quite shaving sharp now but still pretty dang sharp, it will still slice paper and cut cardboard.

Very tough stuff. I will use it again.

My son in law is getting this one.

Greg

I tested my Elmax knife a few days ago and am impressed.

Chopped 2x4's, chopped tree branches, then sliced up three cardboard boxes.

Still shaving sharp at this point. Chopped more 2x4's, chopped more tree limbs.

Shaved curls off of plywood, cut more cardboard.

Chopped 1/8 inch brass rod with the help of a mallet, shaved brass rod.

Sabbed the point as deep into a 2x4 as I could, then bent side ways to try to break it off.

I did this about a hundred times, almost dug a hole through the board.

Tip showes no damage at all.

Knife is not quite shaving sharp now but still pretty dang sharp, it will still slice paper and cut cardboard.

Very tough stuff. I will use it again.

My son in law is getting this one.

Greg