MTBob

Well-Known Member

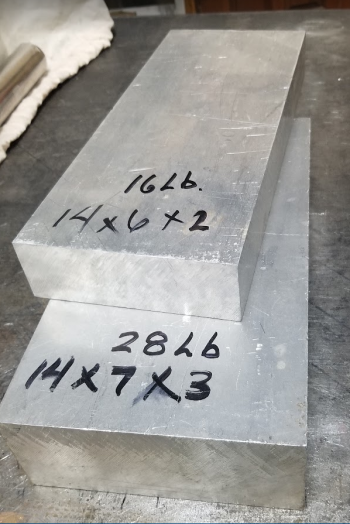

I'm setting up to heat treat stainless steel. I dug around in my junk pile and found 2 blocks that seem like they would work for most of my knife sizes.

Rather than building some kind of vice clamp arrangement, I'm thinking that the weight of the blocks should be adequate for heat transfer.

I"ll add a handle to the small block and put the knife / pouch between the two blocks.

Will that be sufficient heat transfer for stainless?

Rather than building some kind of vice clamp arrangement, I'm thinking that the weight of the blocks should be adequate for heat transfer.

I"ll add a handle to the small block and put the knife / pouch between the two blocks.

Will that be sufficient heat transfer for stainless?