Mark Barone

Well-Known Member

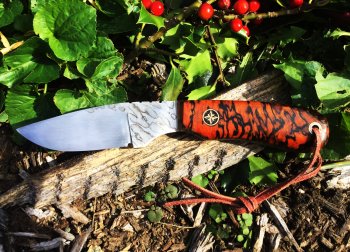

Here is a glamour shot of my second knife I ever made. Its 1095 steel. I used a modified 4 x 36 and 3000 dollars worth of sanding belts. I didn't give up. I believe that's a walnut burl. The plunge lines look alright but I need practice. It has a mustard finish ( to hide some blemishes I don't like.) I had a great deal of fun making it. It's an expensive hobby if you don't know what you are doing. I'm so addicted but can't afford a KMG type grinder. Will a grizzly be an ok step up. I need to improve my plunge lines and use belts that last longer. The 4 x 36 and 1 x 30 belts seem to wear out quickly and the tracking stinks. Other tools I have, HF bandsaw for scales, dremel for tight curves, angle grinder to cut out blank. I don't much but I have been on this site learning a great deal from everybody. I do appreciate this site.