You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

why do i need a disc sander - educate me

- Thread starter lerman

- Start date

Calvin Robinson

Moderator Christian Forum

Yes,build one.

Tom Militano

KNIFE MAKER

I use mine quite a lot.

Frank Niro

KNIFE MAKER

Fred it looks like you have a Rod Nielsen magnetic disc attached to the motor. I have a complete set up with the self centering discs because of the center cut out, a variable speed motor and one that also will reverse. I just got this. No, I ,haven't used it much yet. Because I usually hollow grind my blades, I don't know if it will make my work better but I do know it will make it easier to do by removing a big amount of hand sanding on the granite slab. I know it will be a huge help when I do flat ground blades which I expect to make more of. Frank

Frank Niro

KNIFE MAKER

I believe you will find that slower speed very handy to have. Frank

12345678910

Well-Known Member

There is video of Knife Maker Tim Hancock, Hosted by Travis Wuertz hammer in showing how he uses the disc in the plunge.

Video quality is crap, hand-held shaky camera, audio is hard to hear and half the people there feel they have to talk over the presenter,

but the info is gold.

I'd love to see Tim Hancock in person.

[video=youtube;sdQmuDFuSG4]https://www.youtube.com/watch?v=sdQmuDFuSG4[/video]

Video quality is crap, hand-held shaky camera, audio is hard to hear and half the people there feel they have to talk over the presenter,

but the info is gold.

I'd love to see Tim Hancock in person.

[video=youtube;sdQmuDFuSG4]https://www.youtube.com/watch?v=sdQmuDFuSG4[/video]

Last edited:

scott.livesey

Dealer - Purveyor

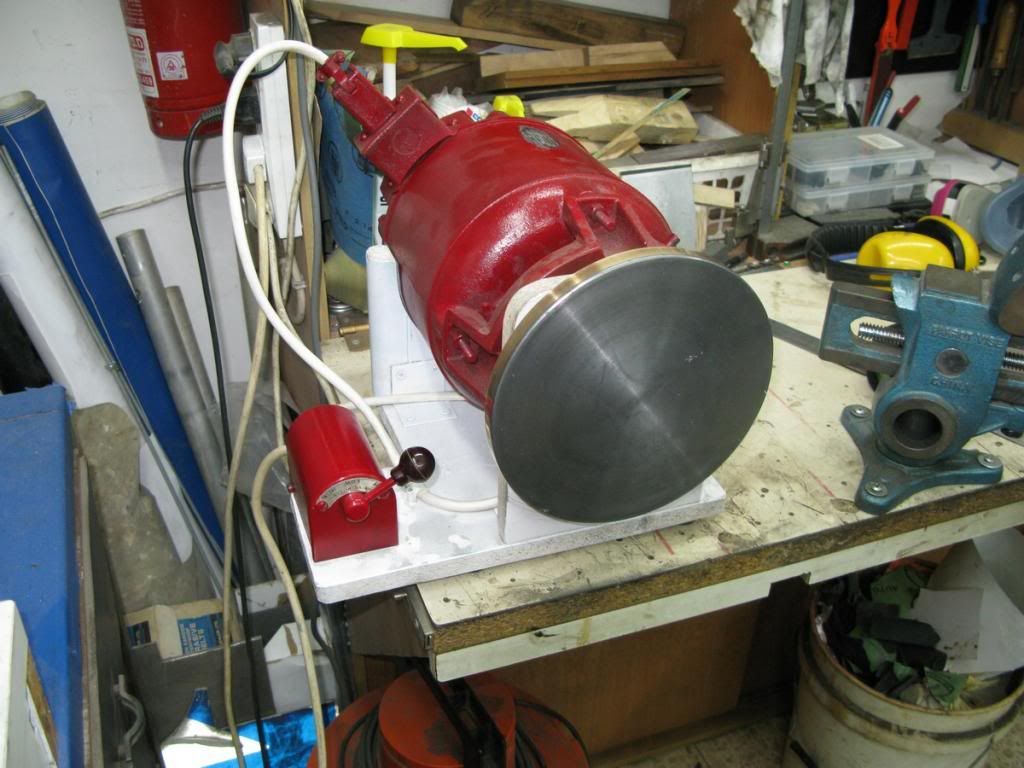

i have mine running, need to clean up the wiring and control panel. 3/4 hp 3 phase motor(TENV/harsh or wet environment) at 1150 rpm, leeson speed master reversible VFD, 8" disc from Covington Engineering. system on/off by AB 15-20 amp motor protector. still working on work table. the linear bearing is the current thought. the vfd is rated for up to 3hp so it has plenty of power available for the motor. the slowest I have run it for testing is 1/3 speed or about 375 rpm, had no issue with stalling. 8" discs seem to be a common size for the rock/jewelry folks, so you can find wet/dry silicon carbide discs up to 1000 grit.

View attachment 40309

View attachment 40309

Last edited:

rhinoknives

Well-Known Member

Lerman,

This looks like it was a loaded question?

Asking why you need one while you were building one, Huh?:biggrin:

There are many uses, but other makers have made great knives without one too.

Your old motor looks like something out of Frankenstein, I love those old beasts and have a few in my shop.

Laurence

www.rhinoknives.com

This looks like it was a loaded question?

Asking why you need one while you were building one, Huh?:biggrin:

There are many uses, but other makers have made great knives without one too.

Your old motor looks like something out of Frankenstein, I love those old beasts and have a few in my shop.

Laurence

www.rhinoknives.com

lerman

Well-Known Member

Lerman,

This looks like it was a loaded question?

Asking why you need one while you were building one, Huh?:biggrin:

There are many uses, but other makers have made great knives without one too.

Your old motor looks like something out of Frankenstein, I love those old beasts and have a few in my shop.

Laurence

www.rhinoknives.com

i honstly started building it just after i saw Tracy's video, but it was a very simple build, i had the motor with the disc platn for years, it was taken of this table that had two sanding discs and motors, so i just had to mount it sideways and lock the platen in place as it was only held in place with a taper when the platen was horizontal.

i really like this old motor with this cool handle

rhinoknives

Well-Known Member

Lee,

I use mine horizontal for truing up scales and blades. I really like the puke green old science lab table you have there. I purchased one from the biology lab at UCLA and use it for a work bench.

Sturdy old thing.

Laurence

www.rhinoknives.com

I use mine horizontal for truing up scales and blades. I really like the puke green old science lab table you have there. I purchased one from the biology lab at UCLA and use it for a work bench.

Sturdy old thing.

Laurence

www.rhinoknives.com

Fred Rowe

Well-Known Member

The Neilsen Interchangable Disk System, like Fred shows has the advantage to have as many flat disks and/or beveled disks as you want or need but need only buy one machine. Check out the system on my web-site and call or e-mail if you need more information.

I agree with Wayne on Mr. Neilsen's disc. I've had mine for three years and plan on adding more disc to the three I already have. When you want to add new paper to a disc, just pop it off the base and turn it face down on a full sheet of the grit paper you desire, trim around the circle and pop it back on. It takes a couple of minutes. I use 3m feathering compound to attach the paper. I bought it from My Coe. good product. Like most good products, the initial cost is more than buying an aluminum disc but what you end up with is worth every penny.