Self Made Knives

Well-Known Member

I have some mystery steel that I've made a couple of test blades out of and it seems to perform pretty well. I was originally told it was D2, but found out today from the factory sales rep that it is in fact A8 tool steel. I tried searching the forum but couldn't find anybody talking about it.

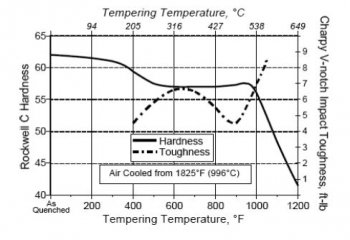

Several sources online state that is tougher than D2 and CPM 3V, but less wear resistant. Sounds like some extreme duty, tough combat type knives have been made out of it. Sales rep said it had 8% chromium, but most online sources are showing more like 5.5%. It will rust, but not easily. I found heat treating instructions for 60 Rockwell.

Sooooo..... I can get nearly all of the A8 steel I could possibly use for free. It is about 3/16" thick, so that's a problem for some designs, but if its free.... I can put it on the mill with a fly cutter and thin if down without too much trouble. What do you guys think? Ever used it? Seems pretty good to me, but I'd like to hear other opinions.

Several sources online state that is tougher than D2 and CPM 3V, but less wear resistant. Sounds like some extreme duty, tough combat type knives have been made out of it. Sales rep said it had 8% chromium, but most online sources are showing more like 5.5%. It will rust, but not easily. I found heat treating instructions for 60 Rockwell.

Sooooo..... I can get nearly all of the A8 steel I could possibly use for free. It is about 3/16" thick, so that's a problem for some designs, but if its free.... I can put it on the mill with a fly cutter and thin if down without too much trouble. What do you guys think? Ever used it? Seems pretty good to me, but I'd like to hear other opinions.