Daniel Macina

Well-Known Member

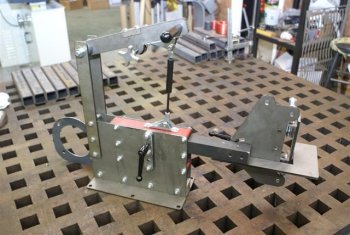

Well I'm partly embarrassed to post this and partly giddy with excitement. I had no idea how exact everything had to be on a grinder and it was certainly a learning experience. Full disclosure these grinders can be built much nicer. If I did it all again I would probably just buy a grinder because of the precision required to build a good grinder. I messed with the tracking for about a week and this was as close as I could get it. Still tracks a little to the right but I've tried and can't get it any closer. As @EdCaffreyMS said no matter what you do the arm that holds the tracking wheel has some side to side flex that will keep you from having perfect tracking unless you find a way to stop it from flexing. I didn't feel comfortable enough to make something to keep it from flexing so it was just left as is. far from perfect but still a huge step up from my harbor freight 1x30. Now for some pics and a short video. Please be brutally honest about what you think. I won't get my feelings hurt.

Can't figure out how to post a video but once I do I'll get it posted.

Ps: yes the VFD got mounted a little crooked. I'll fix it. Lol.

Can't figure out how to post a video but once I do I'll get it posted.

Ps: yes the VFD got mounted a little crooked. I'll fix it. Lol.