Daniel, you mention preferring a 3hp - you full time? I can maybe see a full time maker like Ed wanting a 3hp so the motor isn't running heavy loaded. For myself, I've got a 2hp with VFD and with it cranked up 100% I'm not sure I could choke it down on an 8" contact wheel. Even the platen which pulls more hp it'd be hard to choke..... OK, I just went to shop and tried to choke with a 50 grit VSM ceramic belt on an old rasp that is 1.5" X 3/8" holding rasp flat so the full 1.5" X 3/8" is being ground. Crank the VFD to max of 3800 RPM for about 4,000 SFPM belt speed and couldn't choke motor - but it sure was throwing some sparks! When I say I couldn't choke there was a max amount of pressure I could apply because the grinder would lift on stand. Had stand been bolted down - maybe I could have choked motor - not sure.

For the price point I don't see any reason for more than 2hp on a 2X72 grinder - especially for the part time maker. Full time is a totally different matter. I'm not full time so will bow to Ed's experience since he's been full time and makes more knives in a week or two than I do in a year.

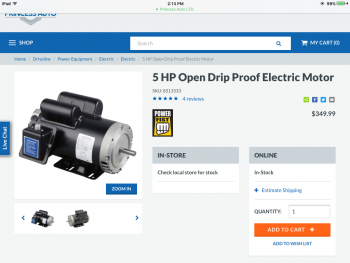

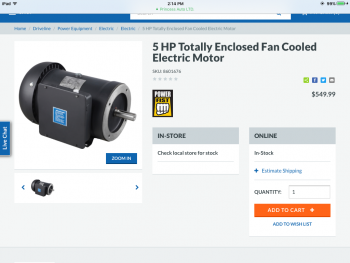

If I had a 1-1/2 hp motor laying around, or found one cheap I wouldn't hesitate to use it. If buying new, the cost difference in 1.5 vs 2 hp is only $12 for a 3600 rpm IronHorse motor. Of course, the 3hp 3600 rpm motor is only $50 more than the 2hp.