N.N

Well-Known Member

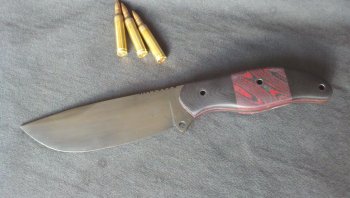

Survival/tactical knives, 3/16" 1095, 5 inch cutting edge.

starting from the top to the bottom, this was the first time I've cut a false edge. I think they turned out pretty good. The curved blade knife I actually screwed up and went over the edge of the stoping point and had to fix it, you might notice it's not perfectly straight and that's why. I was scared to go too much further with it. But I plan to keep this knife, so it doesn't bother me.

It's the first time I've stonewashed a blade as well. Before the bluing, I could tell that it was stonewashed, but after, you can't even notice. I was doing it like this because I heard that stone washing first would make the bluing more of a dull black. These are still a little shiny, so maybe I need to go further with it next time.

This is also the first heat treat that I've had to really give me a good warp. I didn't think I was going to get it straight again, but it's close enough for these 2. The dewcarta knikfe is going to be mine, the other is for a buddy. So answer this question if you want....when you have a warp, do you get it perfectly (and I mean perfectly) straight before you finish it or will you actually get it pretty close so there's no gapping in the handle/tang area and roll with it? I'm just curious. These two you would have to look pretty close to see it now.

Drawing

Cutting

heat treating

handle layout

Bluing

Gluing

I went back and forth so many times with this dewcarta stuff....I don't think I like it, I like it, I dont' know about those colors or if I should shape it like everybody else is going to or not.... Anyway, The first green set I received from the contest was flawed. After a conversation with Mr. Dewey in another thread, he sent me another sample of the newer stuff....big difference. I could tell right away that the red was much bettter done. So thanks for that kind Sir!

in another thread, he sent me another sample of the newer stuff....big difference. I could tell right away that the red was much bettter done. So thanks for that kind Sir!

Anyway, unlike the other threads on the subject, I did not have to CA the finish and keep going up in grit. I actually stopped where you see here with 400 and then oiled it. This seemed to work fine, but I might go back later and do the CA then up to at least 600. In fact, I probably will hit it a little bit more a little later. It has more texture than the g10 at 400 grit, but it's smooth, not fabric-y. It doesn't sand on the belt quite as quickly or easily as g10 or micarta, but it wasn't bad. I intentionally didn't hit it with anything lower than an 80 belt though, to keep it from fraying or ruffling up as those of you who have handled it could imagine it might do.

I decided to use the dewcarta as an accent because personally I don't like the round/wavey pattern you can see would be the obvious way to finish it. However, like this, I think it really came out nice and I think I like it. I've got enough left over that I'm thinking about using it for my first friction folder.

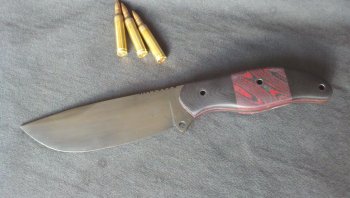

starting from the top to the bottom, this was the first time I've cut a false edge. I think they turned out pretty good. The curved blade knife I actually screwed up and went over the edge of the stoping point and had to fix it, you might notice it's not perfectly straight and that's why. I was scared to go too much further with it. But I plan to keep this knife, so it doesn't bother me.

It's the first time I've stonewashed a blade as well. Before the bluing, I could tell that it was stonewashed, but after, you can't even notice. I was doing it like this because I heard that stone washing first would make the bluing more of a dull black. These are still a little shiny, so maybe I need to go further with it next time.

This is also the first heat treat that I've had to really give me a good warp. I didn't think I was going to get it straight again, but it's close enough for these 2. The dewcarta knikfe is going to be mine, the other is for a buddy. So answer this question if you want....when you have a warp, do you get it perfectly (and I mean perfectly) straight before you finish it or will you actually get it pretty close so there's no gapping in the handle/tang area and roll with it? I'm just curious. These two you would have to look pretty close to see it now.

Drawing

Cutting

heat treating

handle layout

Bluing

Gluing

I went back and forth so many times with this dewcarta stuff....I don't think I like it, I like it, I dont' know about those colors or if I should shape it like everybody else is going to or not.... Anyway, The first green set I received from the contest was flawed. After a conversation with Mr. Dewey

Anyway, unlike the other threads on the subject, I did not have to CA the finish and keep going up in grit. I actually stopped where you see here with 400 and then oiled it. This seemed to work fine, but I might go back later and do the CA then up to at least 600. In fact, I probably will hit it a little bit more a little later. It has more texture than the g10 at 400 grit, but it's smooth, not fabric-y. It doesn't sand on the belt quite as quickly or easily as g10 or micarta, but it wasn't bad. I intentionally didn't hit it with anything lower than an 80 belt though, to keep it from fraying or ruffling up as those of you who have handled it could imagine it might do.

I decided to use the dewcarta as an accent because personally I don't like the round/wavey pattern you can see would be the obvious way to finish it. However, like this, I think it really came out nice and I think I like it. I've got enough left over that I'm thinking about using it for my first friction folder.

Last edited: