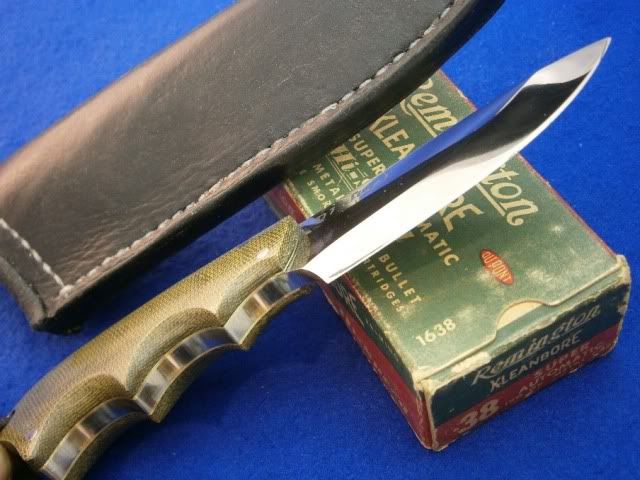

Ausbrooks

KNIFE MAKER

Made this EDC for my college student nephew who turns out is into knives and and has a Gerstner full and never told me. I told him I'd make a knife for him, and his only requirement was something in green micarta, and left rest up to me. Design is a three finger with shortened tip design, thus the bluntness. This was one of those "fight me all the way" knives and took many hours to polish the D7, and another belt order. Thanks for looking.

Specs-

Blade: D7 61RC 3 cryo 4 tempers

Handles: Green canvas micarta w. brass spacers

Hrdwr: 416 SS pins and tube

Sheath: 6oz leather w. suede lining and steel belt clip, hand stitched

Specs-

Blade: D7 61RC 3 cryo 4 tempers

Handles: Green canvas micarta w. brass spacers

Hrdwr: 416 SS pins and tube

Sheath: 6oz leather w. suede lining and steel belt clip, hand stitched