Anthony, your words put me into thought check out these sites, most are for CNC machines, some have cobalt flutes. I wasn't sure how familiar you were with routers.

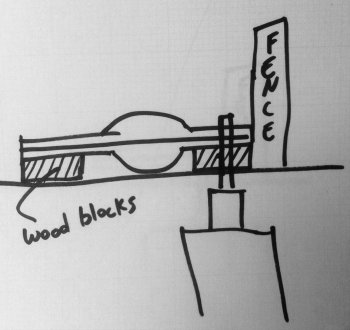

You can even use stops on a router table. All you have to do is set the stop so that your material can only move from start point of your cut to stopping point. The material slide on the router table acts as your third guide. Even with CNC machines the router makes a pass and then lifts straight up, goes back to starting point and plunges in and makes the next pass, and then repeat to desired depth!!

Guides and stops are truly your best friend when it comes to handling a router by hand and precision. Make practice cuts on a scrap and get all the bugs worked out before you make a pass on the good stuff!!

Just reread your post again:

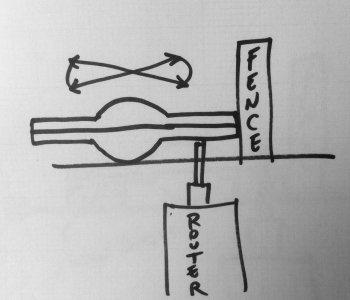

Yeah C, I use a router table with a fence for this and it is a blind plunge. The bit is more grabby in one direction that the other, but since you're plunging blind I can't start the cut exactly at the beginning of a slot. I have to plunge in close to the end, and go and back and forth a little to complete the slot. I know the cnc router guys mill plastic a lot so I'm guessing there are plastic specific bits. Hoping somebody on here has kydex specific experience to save me some time.

Are you plunging the router or are you trying to plunge the material onto the router bit?

Plunging the material onto the bit is a recipe for mistakes.

A good router table set up where you can actually plunge the router

up into the material is not cheap. That takes a plunge router and a top of the line router table. Years ago I bought a cheap one and well................. I soon figured out I had a table with a straight edge and it did not work well for anything I wanted to do!! I went thru about 3 routers till I realized if I wanted one that worked well I had to buy a plunge router and learn how to use it!

Quick story, I recently had my son help me move everything out of my shop when we had a plumbing pipe bust and the plumber needed access to attic and floor, recently! Anyway my son helps me with a jig I made for cutting adjustable pegs for a book case. He was a little rough with it and I got on his case.

"Son you may not realize it but that is about $2800 of jig you are slinging around"

What he says! I told him when I was building all those book cases a few years back I priced a jig to do this. I found one that was 4' in length and had to be set-up and moved, even if you wanted to do an 8' tall case. They wanted almost $1200 for it.

So I made that one and if you set this one up for it you can cut up to a 12' height on a bookcase. Once you get the jig set and the router set up I can do like a 12' piece in a matter of 3-5 minutes with no mistakes. So now you know to take care of it!!! As I stated earlier jigs are your best friend for router work!!

https://www.amanatool.com/products/cnc-router-bits/plastic-cutting-cnc-router-bits.html

Here is some from Amazon.

https://www.amazon.com/router-bits-plastic/s?page=1&rh=i:aps,k:router bits for plastic

https://www.toolstoday.com/cnc-router-bits-and-insert-bits/plastic-cutting-cnc-router-bits.html

Call some of these companies that supply plastic cutting bits, and ask to speak to the techs, most of them can tell you what you need for what you are trying to accomplish with the bits!!