Mark Behnke

Well-Known Member

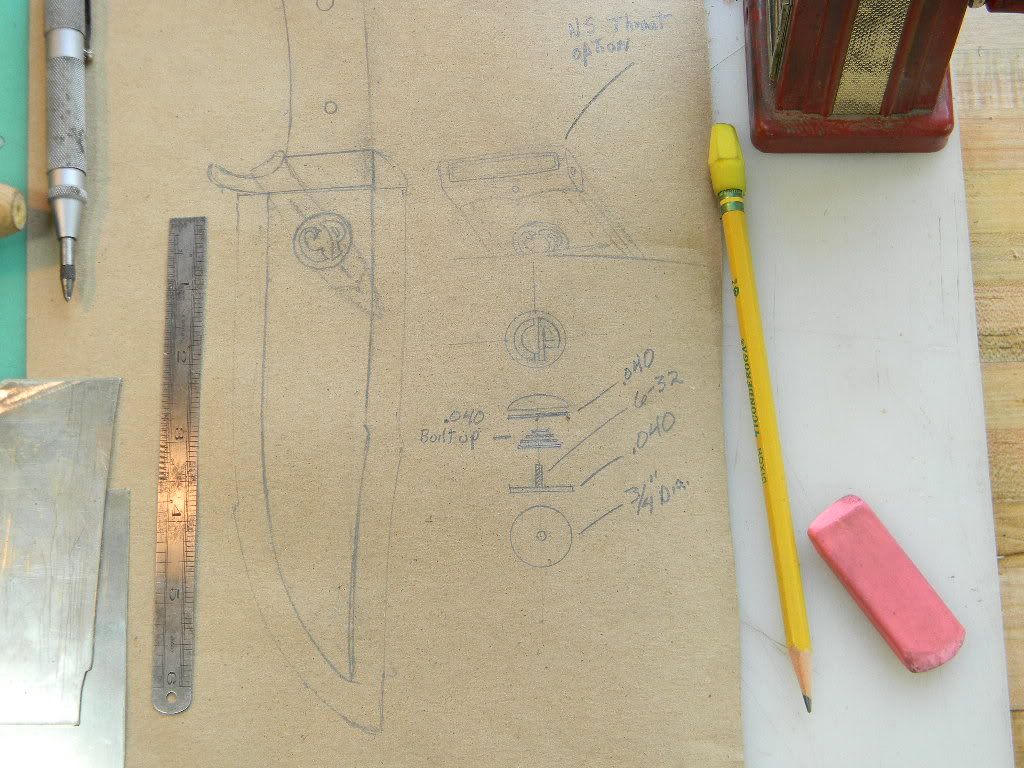

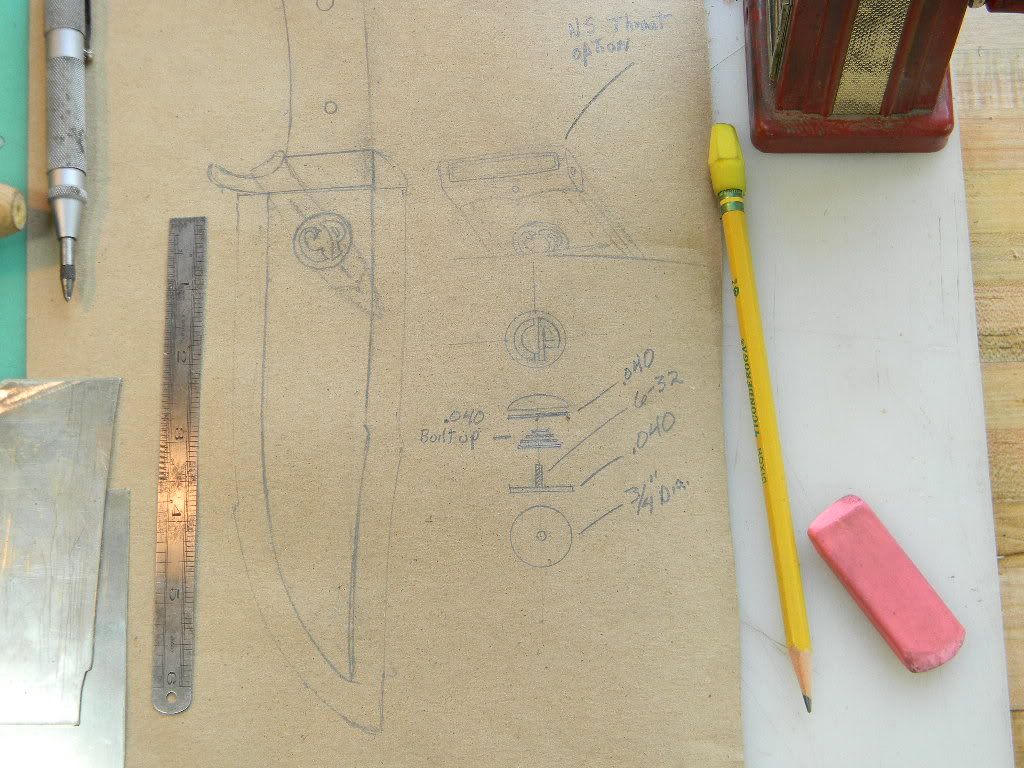

The plan is to fabricate a Button using nickle silver sheet stock and hard silver solders.

It will look like a little mushroom so I'm going to label the parts, Base Stem and Cap.

The base will be a 3/4" disc .040" thick.

The stem will be of several .040" discs stacked, drilled and tapped.

The Cap will be 3/4" dia. consisting of a base and dome with decorative layers (overlay).

I'm no expert at this but I have done two before and have done some silver work years ago. Just added it up, 38 yrs. ago. Get busy, time flys. There's easier ways to do this but I'm using the materials and tools on hand.

Oxy-propane torch and hard silver solders.

Here's a sketch of the basic plan. The overlay will change but the procedure won't.

First step is to cut out the discs. They make a disc cutter that works on the same principal as a paper punch but I don't have one so it's bandsaw, snips, grinder, and jewelers saw.

That's all for today, I'll post more tomorrow, Thanks for looking.

It will look like a little mushroom so I'm going to label the parts, Base Stem and Cap.

The base will be a 3/4" disc .040" thick.

The stem will be of several .040" discs stacked, drilled and tapped.

The Cap will be 3/4" dia. consisting of a base and dome with decorative layers (overlay).

I'm no expert at this but I have done two before and have done some silver work years ago. Just added it up, 38 yrs. ago. Get busy, time flys. There's easier ways to do this but I'm using the materials and tools on hand.

Oxy-propane torch and hard silver solders.

Here's a sketch of the basic plan. The overlay will change but the procedure won't.

First step is to cut out the discs. They make a disc cutter that works on the same principal as a paper punch but I don't have one so it's bandsaw, snips, grinder, and jewelers saw.

That's all for today, I'll post more tomorrow, Thanks for looking.

Last edited: