Goot

Well-Known Member

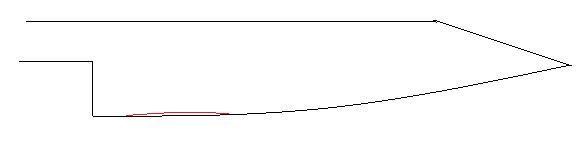

I have a recurring problem with the edge of my chef knives after I begin sharpening a finished knife. The bevels are ground, everything else is done, and the edge profile is good and flat near the heel. However, when I finish sharpening and check the edge against my granite slab, I notice that there's a small divot in the edge about two inches from the heel that lifts away causing light to shine through. It's not super apparent, but it's enough to be a problem. It's a pain in the neck to fix especially when the rest of the blade is sharp. See the picture above with the red divot.

I figured that this was occurring due to an uneven bevel grind -- the "two inch divot" referenced by Walter Sorrells in his youtube video. I made a new knife making sure I was being careful with my body positioning and angles on the platen, but it happened again! I'm getting to the point where I want to make the belly larger near the heel in my initial profile to mitigate this, but that's not solving the problem. It only starts showing as I'm sharpening.

Am I on the right track with the cause of this? Do I just need more practice grinding bevels?