You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

hand stitching vs industrial sewing machine?

- Thread starter Smallshop

- Start date

Smallshop

KNIFE MAKER

Rick Otts

Well-Known Member

Sorry Small I couldn't find it but I would look at it like this if they were any good Ed would have one.

bodam

Well-Known Member

I recently bought a Boss stitching machine. You can set them in a groove, I do it every day.

That being said, I'm still learning how to start and finish stitches, they don't come out as clean as hand stitching. But other than that learning curve, the stitches are clean, they set into the leather, and is much faster and easier than hand stitching.

Of course, I'm into this new Boss for over $1,500, but once you have one, you probably will never hand stitch another 29 stitches...

That being said, I'm still learning how to start and finish stitches, they don't come out as clean as hand stitching. But other than that learning curve, the stitches are clean, they set into the leather, and is much faster and easier than hand stitching.

Of course, I'm into this new Boss for over $1,500, but once you have one, you probably will never hand stitch another 29 stitches...

Smallshop

KNIFE MAKER

So....I had bought a "speedy stitcher" over a year ago. Yesterday I was using it(for the first time) and LOVING it.and then it hit me....this is NOT the same stitch I am doing with two needles and sore thumbs...lol. The threads are crossing in the middle and never up 'n' over....so I looked it up....the speedy stitcher and most leather sewing machines are doing a lock stitch...not as strong as a saddle stitch. Does it matter? I dunno....but I want my sheaths to be as strong as possible...until I can test between the two, I will continue to bang out the ol' 29 by hand...lol.

Here's a quote from Doug lester from the KD link Rick O. told us about...: "....Also a machine stitch is not all that durable. Start one thread going and it will zip apart. A good saddle stitch will hold even if the thread breaks somewhere along the line."

Zip apart...like a big sack of dog food?

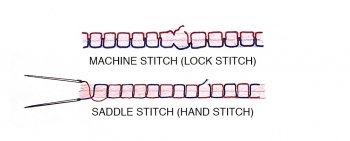

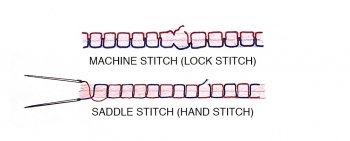

In case you have never thought about it here is a diagram(from Teller leather) of the two types of stitches:

Of course the rational side of me thinks....if a lock stitch was so bad how are the industrial sewing machine companies selling so many machine? especially to the tune of $1500 plus? It's always about degree of quality...hmm? Like if I did a double row of lock stitch wouldn't it still be better than a single row of saddle stitch? And still MUCH faster!!

If I can bury a stitch in a groove it probably is apples to oranges. the main stitch on a sheath is a no work zone. It's stiff and just holds the knife...as long as you cannot rub the stitch ( bodam's machine lays it in the groove) you should be fine....correct?

Just thinking (typing) out loud here...

Here's a quote from Doug lester from the KD link Rick O. told us about...: "....Also a machine stitch is not all that durable. Start one thread going and it will zip apart. A good saddle stitch will hold even if the thread breaks somewhere along the line."

Zip apart...like a big sack of dog food?

In case you have never thought about it here is a diagram(from Teller leather) of the two types of stitches:

Of course the rational side of me thinks....if a lock stitch was so bad how are the industrial sewing machine companies selling so many machine? especially to the tune of $1500 plus? It's always about degree of quality...hmm? Like if I did a double row of lock stitch wouldn't it still be better than a single row of saddle stitch? And still MUCH faster!!

If I can bury a stitch in a groove it probably is apples to oranges. the main stitch on a sheath is a no work zone. It's stiff and just holds the knife...as long as you cannot rub the stitch ( bodam's machine lays it in the groove) you should be fine....correct?

Just thinking (typing) out loud here...

Last edited:

John Wilson

Well-Known Member

playing devil's advocate:

If a machine stitch was insufficient, every sheath and holster maker in history would have a bad name. Look, I'm all for hand stitching (since I don't have a machine) but let's be honest here - how much abuse is a knife sheath supposed to take before the stitching becomes a failure point? Especially if you use contact cement to hold it together in first place? As far as a running stitch pulling out, that's a good reason to put a tiny tab of super glue on the bitter end and lay it down flat.

I get that things fail, but here is where it becomes appropriate to discuss what constitutes normal wear and tear. If you wear the stitches off your knife sheath I have to ask how you managed to do that. I have to ask if you also wore your hip out rolling back and forth over your knife while taking transmissions out in your driveway every night. You didn't think to take your knife off?

The old sheaths I've seen with the stitches falling out were victims of age and dry rot.

I groove my sheaths and hand stitch, but if I had a machine I'd use it and never look back.

If a machine stitch was insufficient, every sheath and holster maker in history would have a bad name. Look, I'm all for hand stitching (since I don't have a machine) but let's be honest here - how much abuse is a knife sheath supposed to take before the stitching becomes a failure point? Especially if you use contact cement to hold it together in first place? As far as a running stitch pulling out, that's a good reason to put a tiny tab of super glue on the bitter end and lay it down flat.

I get that things fail, but here is where it becomes appropriate to discuss what constitutes normal wear and tear. If you wear the stitches off your knife sheath I have to ask how you managed to do that. I have to ask if you also wore your hip out rolling back and forth over your knife while taking transmissions out in your driveway every night. You didn't think to take your knife off?

The old sheaths I've seen with the stitches falling out were victims of age and dry rot.

I groove my sheaths and hand stitch, but if I had a machine I'd use it and never look back.

Last edited:

Smallshop

KNIFE MAKER

Pretty much my thinking John....Otherwise Smith and Wesson, etc. would have to employ THOUSANDS of fat thumbed individuals..If a machine stitch was insufficient, every sheath and holster maker in history would have a bad name. Look, I'm all for hand stitching (since I don't have a machine) but let's be honest here - how much abuse is a knife sheath supposed to take before the stitching becomes a failure point? Especially if you use contact cement to hold it together in first place? As far as a running stitch pulling out, that's a good reason to put a tiny tab of super glue on the bitter end and lay it down flat.

I get that things fail, but here is where it becomes appropriate to discuss what constitutes normal wear and tear. If you wear the stitches off your knife sheath I have to ask how you managed to do that. I have to ask if you also wore your hip out rolling back and forth over your knife while taking transmissions out in your driveway every night. You didn't think to take your knife off?

The old sheaths I've seen with the stitches falling out were victims of age and dry rot.

bodam

Well-Known Member

I hand stitched my first 2 belts. And then I decided I wanted a machine.

Once I got the machine, knocking out holsters takes about 10 minutes. My style sheath with stitch on one side, takes about 6.

Not gonna argue the quality of one stitch against another, but quality of time and life beats both hands down, lol.

Once I got the machine, knocking out holsters takes about 10 minutes. My style sheath with stitch on one side, takes about 6.

Not gonna argue the quality of one stitch against another, but quality of time and life beats both hands down, lol.

bodam

Well-Known Member

I usually groove the top only, I've never had good luck with the stitches mating up with the bottom groove. With hand stitching or machine lol.Yes. Can you groove both sides and still get the stitches in the grooves?

Smallshop

KNIFE MAKER

For hand stitching I groove the front , then I glue the welt to the inside of the front part of a folded sheath...then i drill through both on a drill press.this keeps everything flat and square AND if I drill three thickness of leather...some of the leather "chips"seem to wad into the glue joints. Doesn't seem to on two thickness.... Then I glue the welt to the inside of the back. and float the drill through the back part.

Then i belt sand the back part to match the front.

Then i groove the back crossing each hole (if my sanding job is correct...lol)

Then i stitch.

Works pretty good for me. Always have to fight the temptation to make the drilled holes too big.(bigger is easier...not better...lol)

Then i belt sand the back part to match the front.

Then i groove the back crossing each hole (if my sanding job is correct...lol)

Then i stitch.

Works pretty good for me. Always have to fight the temptation to make the drilled holes too big.(bigger is easier...not better...lol)

bodam

Well-Known Member

That's pretty much how I did it, but I glued top and bottom with welt. Shaped on sander then ran the groove once the edge was shaped. Then I would drill. But for some reason, the drilling would never match up.

hand stitching you are able to pull that stitch really tight and kind of set it though, it always worked out for me.

hand stitching you are able to pull that stitch really tight and kind of set it though, it always worked out for me.

Smallshop

KNIFE MAKER

I tried that...the drilling is difficult because the surface is no longer flat so the drill goes through wonky. By doing top and welt first your drilling is perfect cause you have a flat area to hold. You do have to use a scrap to shim up the main leather so you're not trying to balance all on the welt surface. then after final gluing the double thickness that is already drilled acts like a drill jig of sorts.

John Wilson

Well-Known Member

How thick of leather can a machine stitch? My typical sheath has 3 layers of 6-7oz leather, but then I have some monsters that are twice that thick.