kevin - the professor

Well-Known Member

Hello Everyone,

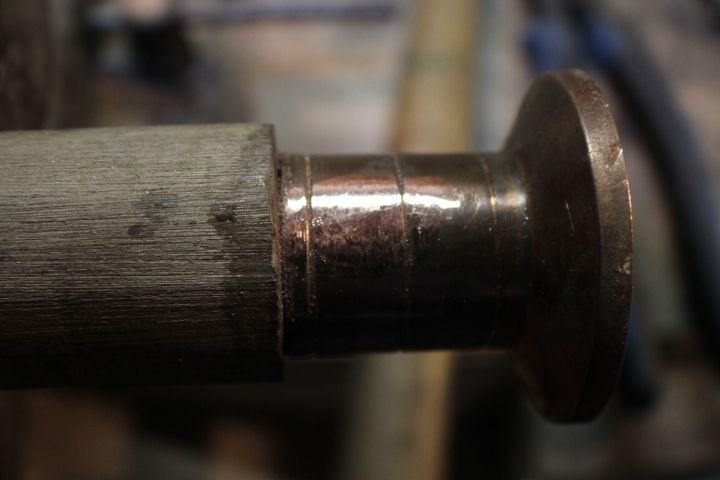

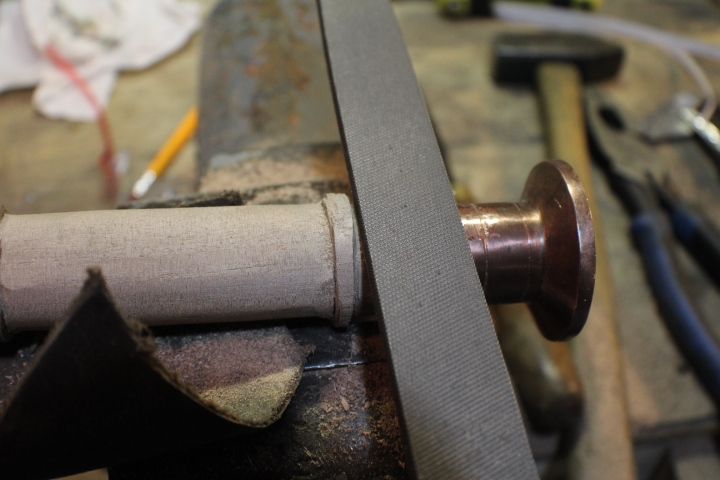

I have a set of beautiful fittings that I got from Charles Wu. These fittings are in the style of the Han Dynasty, and they are sized for a short sword. Therefore, I am making what is known as a, "duan jian," - which is a double-edged short sword.

The pattern is what I call a River pattern, due to the lines of 15N20 that run up the blade, as well as all of the swirls and eddies. This length of blade was quite popular during the Han (as was a very long battle sword of similar proportions but longer dimensions). I think this would have been used by pirate and merchant alike (after all, there isn't a ton of difference).

Aggressive bargaining tool.

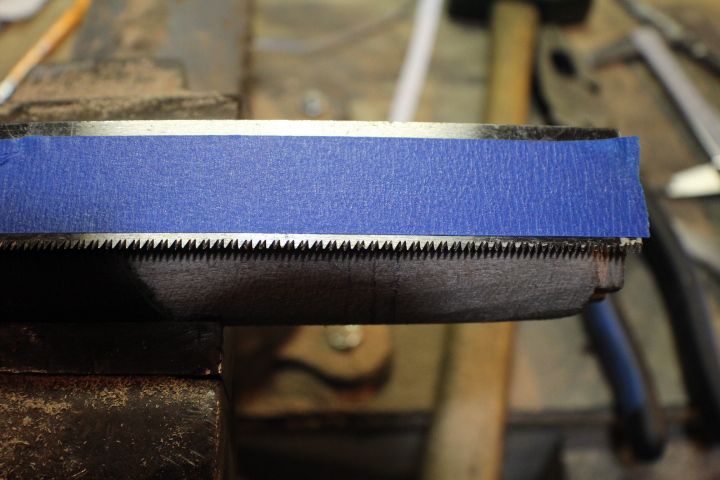

The blade is essentially done, although I still have to do just a tad of refinement of the tip. After that comes the woodwork.

I hope you like. Comments are welcomed.

Bar of crushed w's in the Twistomatic 3000, ready for twisting. This allows me to twist at welding heat, then scoot the forge along rail an inch, and then twist again. It takes the anxiety out of twisting, and should lead to very strong welds when twisting is done, since twists are made at welding heat.

This is the packet for the 4-way mosaic. This is twisted, crushed w's, placed in the corners of a cross made of 15N20.

Tip

ridge

Whole thing: 21.5" long, 1.25" at shoulders, .27" thick at forte, tapering to .13" about 4 inches from tip, and remaining about that size. I heat treated this (tempered) to between an RC of 56 and 58, using harness testing chisels from Matt Parkinson to test every inch or so on each bevel.

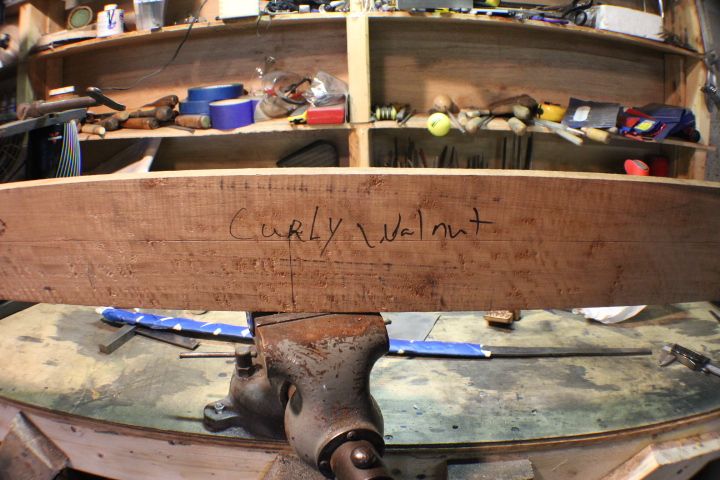

Now, I have to do the wood work. The fittings are great. You will see...

thanks for looking.

kc

I have a set of beautiful fittings that I got from Charles Wu. These fittings are in the style of the Han Dynasty, and they are sized for a short sword. Therefore, I am making what is known as a, "duan jian," - which is a double-edged short sword.

The pattern is what I call a River pattern, due to the lines of 15N20 that run up the blade, as well as all of the swirls and eddies. This length of blade was quite popular during the Han (as was a very long battle sword of similar proportions but longer dimensions). I think this would have been used by pirate and merchant alike (after all, there isn't a ton of difference).

Aggressive bargaining tool.

The blade is essentially done, although I still have to do just a tad of refinement of the tip. After that comes the woodwork.

I hope you like. Comments are welcomed.

Bar of crushed w's in the Twistomatic 3000, ready for twisting. This allows me to twist at welding heat, then scoot the forge along rail an inch, and then twist again. It takes the anxiety out of twisting, and should lead to very strong welds when twisting is done, since twists are made at welding heat.

This is the packet for the 4-way mosaic. This is twisted, crushed w's, placed in the corners of a cross made of 15N20.

Tip

ridge

Whole thing: 21.5" long, 1.25" at shoulders, .27" thick at forte, tapering to .13" about 4 inches from tip, and remaining about that size. I heat treated this (tempered) to between an RC of 56 and 58, using harness testing chisels from Matt Parkinson to test every inch or so on each bevel.

Now, I have to do the wood work. The fittings are great. You will see...

thanks for looking.

kc