Bill Hubbell

KNIFE MAKER

I am one thankful man! My brother called the other day and said his boss had a heat treat oven that they were getting rid of (as in mine for the taking!). He works at a tool & die/machine shop. His boss had bought it used, but never hooked it up. He ended up buying a new oven instead, and didn't want to fool around trying to sell this one. I didn't waste any time getting there, and I now have it sitting on my truck. It's much larger than I expected. The pictures I included here are from one listed on ebay. The one I have is a little larger but otherwise looks similar (same brand).

It came with a bunch of graphite boxes for atmospheric control. Don't let my use of the big words fool you- I had never even heard of those before, but have just been researching the company's website. That looked interesting- like a good way to avoid de-carb.

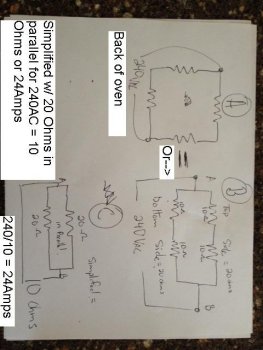

This oven is larger than I need- physically. Has a larger footprint than I wished for. But it looks like 'industrial strength'. One problem is: it's 3-phase, which I don't have, and know little about. There's a separate metal box/cabinet with it that I was hoping would be a phase splitter, but I'm suspecting that it might be a contactor?

Here's some specs:

Sentry Electric Furnace

Size 5

Model AY

33 KW

220 V

87 amps

3-phase

I think the oven measured about 9" Wide, 7" High, and 20 inches deep.

The dial goes to 3,00 degrees, but someone put a label-maker label on that says "Max Temp 2500 degrees"

I've been getting by so far with a home-built gas forge, but have been dreaming of building an oven.

I would value you guys' thoughts on this one:

Should I try to modify it to run on single phase?

Should I strip it out and install new elements and a controller to run on 1 phase,220?

Should I sell it or barter to try to work myself into a newer smaller oven?

Would the mass of the firebrick be a detriment- as in take forever to heat up if I switched out to a lesser heating element, etc?

Are the graphite boxes a good way to go for knives?

I've worked with steel most of my life, as in fabrication, etc. but have never used a heat treat oven, and I've only made a half dozen knives, so-

I would REALLY appreciate any input on this!

Thanks,

Bill

It came with a bunch of graphite boxes for atmospheric control. Don't let my use of the big words fool you- I had never even heard of those before, but have just been researching the company's website. That looked interesting- like a good way to avoid de-carb.

This oven is larger than I need- physically. Has a larger footprint than I wished for. But it looks like 'industrial strength'. One problem is: it's 3-phase, which I don't have, and know little about. There's a separate metal box/cabinet with it that I was hoping would be a phase splitter, but I'm suspecting that it might be a contactor?

Here's some specs:

Sentry Electric Furnace

Size 5

Model AY

33 KW

220 V

87 amps

3-phase

I think the oven measured about 9" Wide, 7" High, and 20 inches deep.

The dial goes to 3,00 degrees, but someone put a label-maker label on that says "Max Temp 2500 degrees"

I've been getting by so far with a home-built gas forge, but have been dreaming of building an oven.

I would value you guys' thoughts on this one:

Should I try to modify it to run on single phase?

Should I strip it out and install new elements and a controller to run on 1 phase,220?

Should I sell it or barter to try to work myself into a newer smaller oven?

Would the mass of the firebrick be a detriment- as in take forever to heat up if I switched out to a lesser heating element, etc?

Are the graphite boxes a good way to go for knives?

I've worked with steel most of my life, as in fabrication, etc. but have never used a heat treat oven, and I've only made a half dozen knives, so-

I would REALLY appreciate any input on this!

Thanks,

Bill