JPSWorks

Well-Known Member

Knife number six slip joint folder with AEB-L steel (Photo Over Load) With Video Now

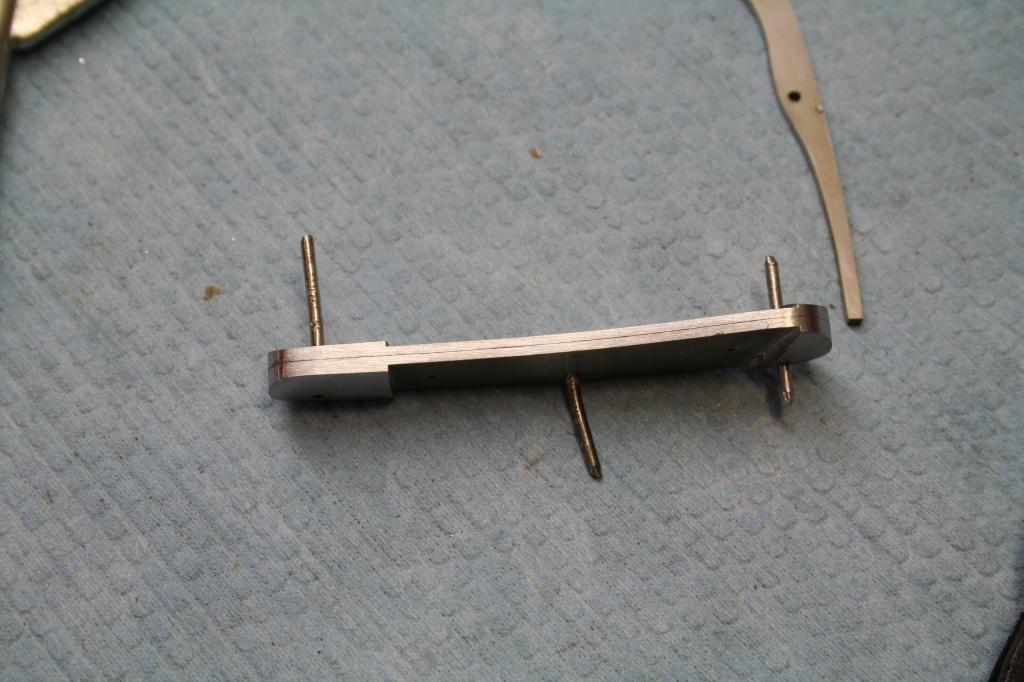

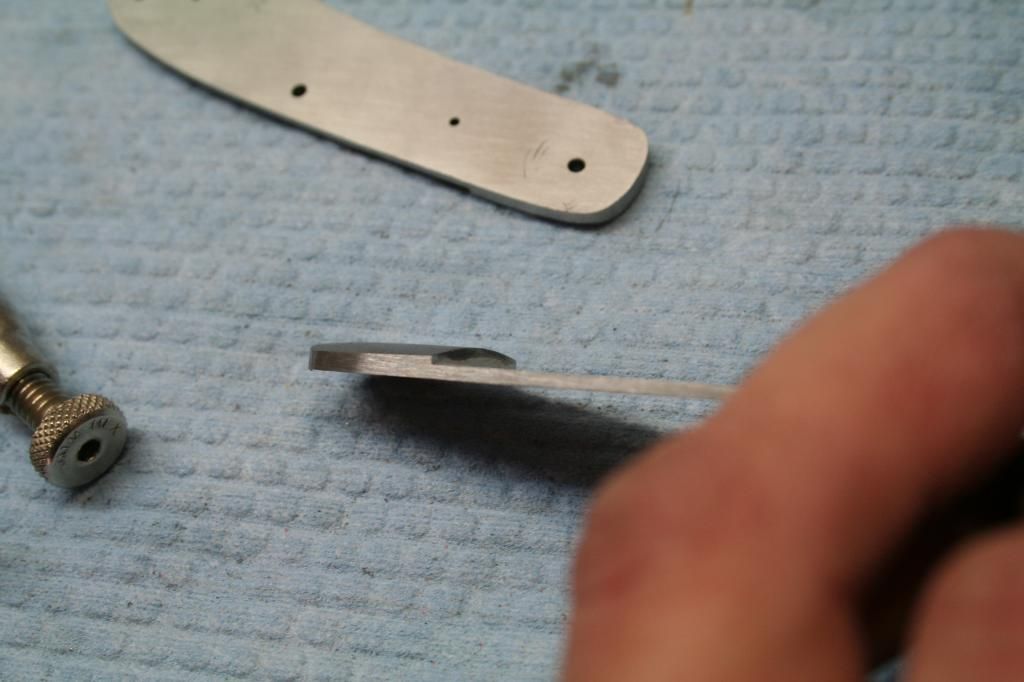

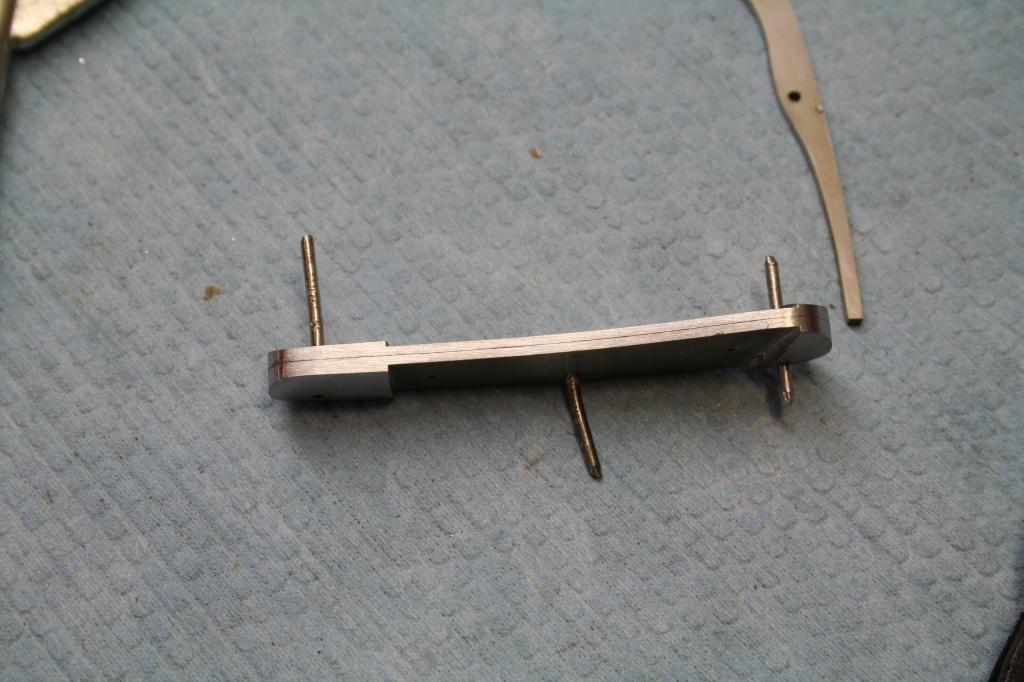

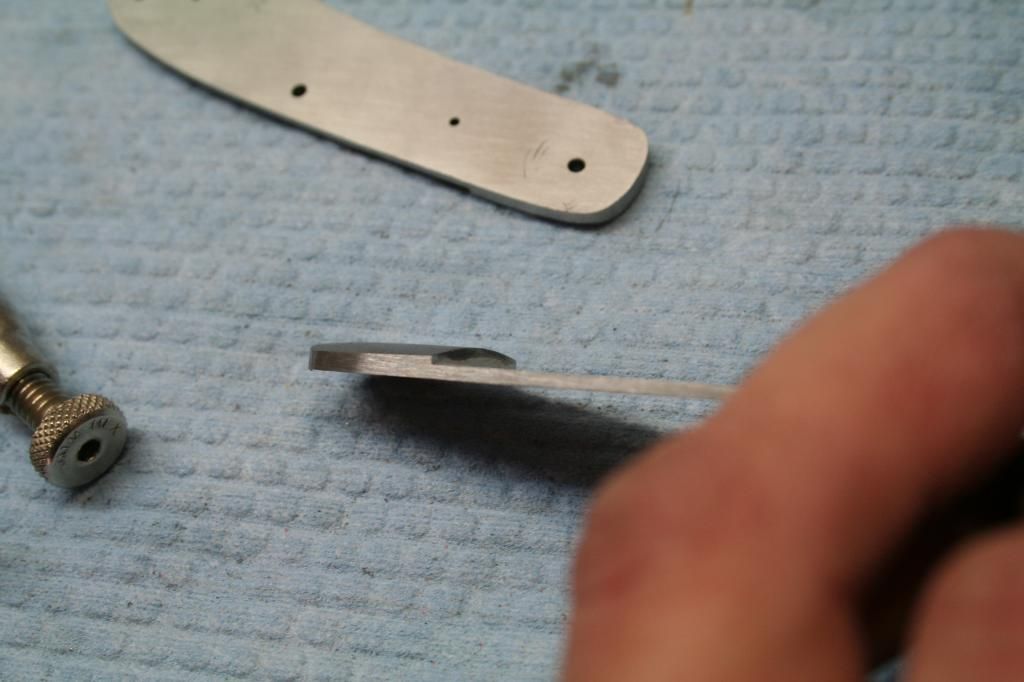

Hello fellow knife dogs. I just completed knife number six two nights ago and was able to take a bunch of pictures yesterday that I would like to post. I am very proud of this knife as I think it is by far the most quality knife I have made to date. I still have a lot to learn mostly trial by error. But I learned a lot on this one. Lesson here was finding the right spring temper temps for the AEB-l steel. 1000 deg for 2 hours is the golden number for me. The second one was using Staybrite flux and solder with stainless steel liners and bolsters. Thanks to everyone who assisted me with these things. I couldn't get pics with bright sunlight since it has been overcast for the last week, so the beautiful stabalized Hawaiian KOA I purches here on Burlsource doesn't show its normal 3 dimensional look in the photos. By the way, I took the pics before I put the edge on the blade as you can see in the pics.

Now don't get me wrong, there are still little issues here and there with scratches I didn't get removed, I need a better nail nick.(the one I did with the dremel in the drill press wasn't deep enough so most of it was ground when grinding the bevel. I also want to get a personalizer, and stencils to put my maker mark on the knives. I still need a lot more grinding time to get the lines even on each side on toward the top of the blade. The ricasso area is at least even since I used my new Bruce Bump file guide and ground free hand on the flat platten of my KMG. But my main goal is to just make each knive better than the last as most suggest on this board. Then one day I might sell one to someone. Currently however I just keep making the knives and keeping them for myself, because flaws and all, I made them and it gives me a great sense of satisfaction to carry or use them.

I also want to thank Gary Crowder for his time and knowledge. I was able to spend a day in his shop in Oklahoma having him teach me how he builds a slip joint folder. I learned a tremendous amount that day, as well as learning that he is a great and generous person who not only made me feel welcome, but he also game me the slipjoint knife that he built for me that day in the shop. He doesn't get on many forums any more and will probably never see this, but I want to give credit where credit is due. Now I just need to find a spot welder so I can start attaching the bolsters that way. Per his recommendation I am going to try to build at least 10 of this type of slip joint so that I can learn the process better before moving on to another design.

Ok on to the pics(photo overload). I can never just choose a couple so I will just post a lot of them here. Hope you don't mind.

PS. I am now working on knives 7 and 8 and 9, all slip joints. Man I love making these knives.

John

Hello fellow knife dogs. I just completed knife number six two nights ago and was able to take a bunch of pictures yesterday that I would like to post. I am very proud of this knife as I think it is by far the most quality knife I have made to date. I still have a lot to learn mostly trial by error. But I learned a lot on this one. Lesson here was finding the right spring temper temps for the AEB-l steel. 1000 deg for 2 hours is the golden number for me. The second one was using Staybrite flux and solder with stainless steel liners and bolsters. Thanks to everyone who assisted me with these things. I couldn't get pics with bright sunlight since it has been overcast for the last week, so the beautiful stabalized Hawaiian KOA I purches here on Burlsource doesn't show its normal 3 dimensional look in the photos. By the way, I took the pics before I put the edge on the blade as you can see in the pics.

Now don't get me wrong, there are still little issues here and there with scratches I didn't get removed, I need a better nail nick.(the one I did with the dremel in the drill press wasn't deep enough so most of it was ground when grinding the bevel. I also want to get a personalizer, and stencils to put my maker mark on the knives. I still need a lot more grinding time to get the lines even on each side on toward the top of the blade. The ricasso area is at least even since I used my new Bruce Bump file guide and ground free hand on the flat platten of my KMG. But my main goal is to just make each knive better than the last as most suggest on this board. Then one day I might sell one to someone. Currently however I just keep making the knives and keeping them for myself, because flaws and all, I made them and it gives me a great sense of satisfaction to carry or use them.

I also want to thank Gary Crowder for his time and knowledge. I was able to spend a day in his shop in Oklahoma having him teach me how he builds a slip joint folder. I learned a tremendous amount that day, as well as learning that he is a great and generous person who not only made me feel welcome, but he also game me the slipjoint knife that he built for me that day in the shop. He doesn't get on many forums any more and will probably never see this, but I want to give credit where credit is due. Now I just need to find a spot welder so I can start attaching the bolsters that way. Per his recommendation I am going to try to build at least 10 of this type of slip joint so that I can learn the process better before moving on to another design.

Ok on to the pics(photo overload). I can never just choose a couple so I will just post a lot of them here. Hope you don't mind.

PS. I am now working on knives 7 and 8 and 9, all slip joints. Man I love making these knives.

John

Last edited: