C Craft

Well-Known Member

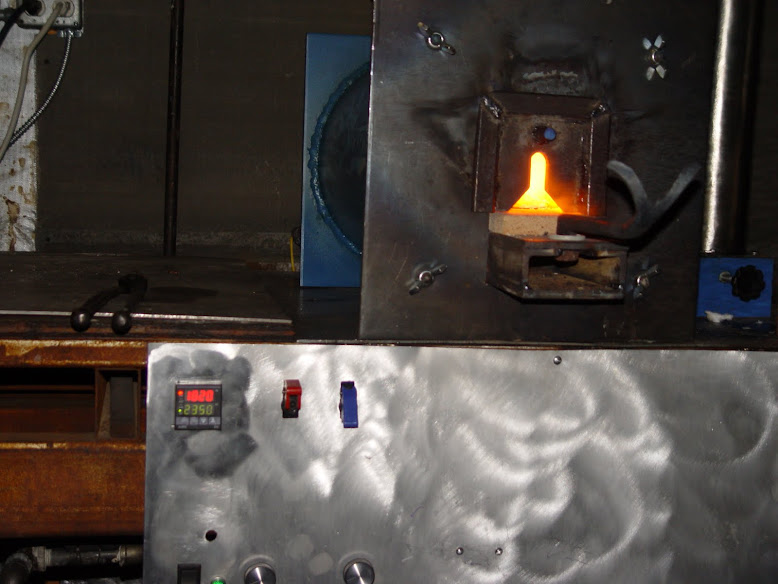

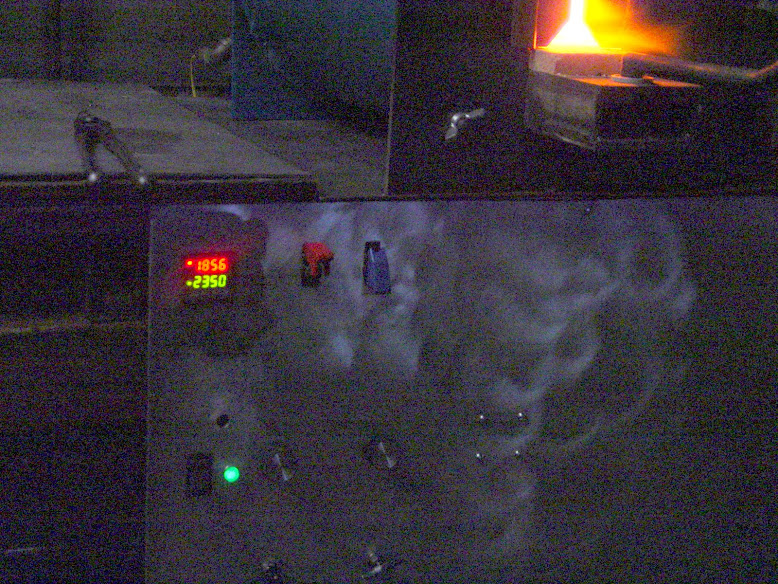

The forge is getting re-worked again, I am actually going to fire this thing soon.:55: Or at least that is what I keep telling myself, it has been a long time coming!:34:

This forge started life like this. Since I have a bad back everything in my shop is on wheels. This was my grinder/forge cart. It has kept evolving.

It has been transformed into this, and I re-named it the War Wagon, from the John Wayne, movie by that name! :biggrin: What, I am a die hard shoot em up, my hero, John Wayne fan. Those were movies worth seeing, those Hollywood guns can shoot for a week before you have to reload. .

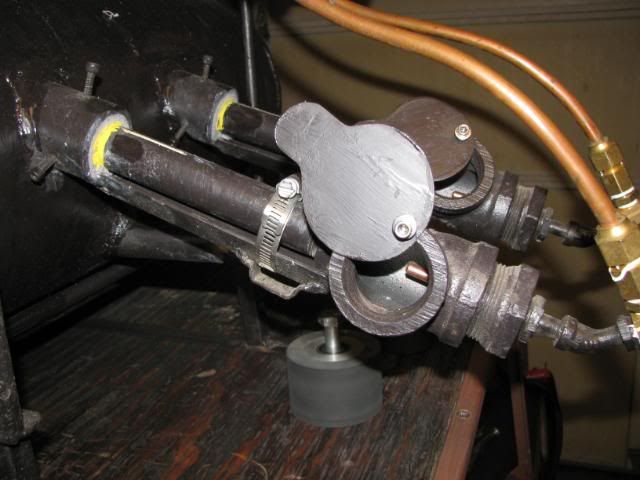

So here are the air chamber W/choke plate I originally designed for these burners.

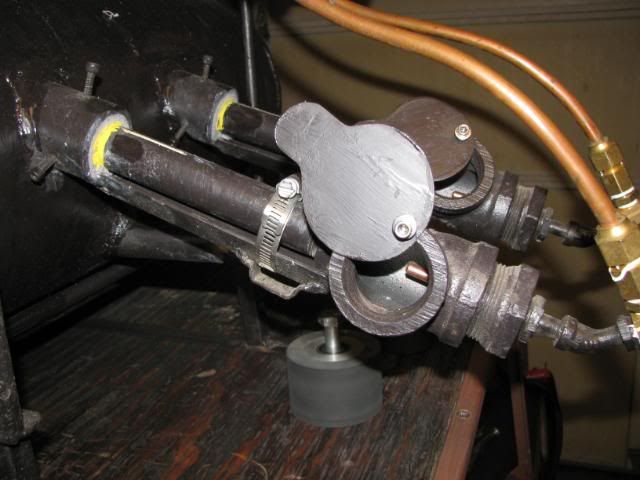

So when I decided to go with a blower on this forge I had to rotate the bell reducer and here are the pieces I just finished fabricating to bring the air supplies to the burners.

Just ignore the junk scattered under the forge as the top has been become a catch-all while I am working on it. Also the pipe wrench will come out of there as well. Needed it in there while I rotated the bell reducers to the other direction. :what!: :biggrin:

I am going to hang a blower on this bad boy, before the day I christen it! So as stated I have been busy fabricating the pick-up pipes for the air supply, and that brings every thing up to date.

Now this is where the the question/s come into play. If you notice on the blue tape on the pieces I have fabricated is.

I am thinking of drilling and installing a couple of those igniter's for a grill at this point. I remember someone saying that they had one set up on their forge. I can't remember for sure but it may have been Bruce Bump! Anyways, I know from experience on my gas grill they don't last long! Also if I do what I am presently thinking about the actual igniter would have to screw in the pipe and so far I haven't been able to find one that is set up to screw in, most are like this one.

Not set up to thread in!!!!

Not set up to thread in!!!!

I am wondering if that is because the grill is outside and exposed to the weather or are they just not worth anything????????

Does anyone use an igniter like this to light their grill????

If so how does it work???

Since I now can't get to the choke plate of the burner to light the burners I have to come up with another train of a thought! I have heard horror stories of someone reaching inside the chamber to light a burner. IE, burned arm hair, singed eyebrows and one case where the guy said it sent him across the room and when his ears quit ringing he realized he no longer had eyebrow or mustache! :what!::cursing: So that kind of makes me leary of that way of lighting the burners!

So how do you light your forge and do you have any suggestions on this one???

This forge started life like this. Since I have a bad back everything in my shop is on wheels. This was my grinder/forge cart. It has kept evolving.

It has been transformed into this, and I re-named it the War Wagon, from the John Wayne, movie by that name! :biggrin: What, I am a die hard shoot em up, my hero, John Wayne fan. Those were movies worth seeing, those Hollywood guns can shoot for a week before you have to reload. .

So here are the air chamber W/choke plate I originally designed for these burners.

So when I decided to go with a blower on this forge I had to rotate the bell reducer and here are the pieces I just finished fabricating to bring the air supplies to the burners.

Just ignore the junk scattered under the forge as the top has been become a catch-all while I am working on it. Also the pipe wrench will come out of there as well. Needed it in there while I rotated the bell reducers to the other direction. :what!: :biggrin:

I am going to hang a blower on this bad boy, before the day I christen it! So as stated I have been busy fabricating the pick-up pipes for the air supply, and that brings every thing up to date.

Now this is where the the question/s come into play. If you notice on the blue tape on the pieces I have fabricated is.

I am thinking of drilling and installing a couple of those igniter's for a grill at this point. I remember someone saying that they had one set up on their forge. I can't remember for sure but it may have been Bruce Bump! Anyways, I know from experience on my gas grill they don't last long! Also if I do what I am presently thinking about the actual igniter would have to screw in the pipe and so far I haven't been able to find one that is set up to screw in, most are like this one.

I am wondering if that is because the grill is outside and exposed to the weather or are they just not worth anything????????

Does anyone use an igniter like this to light their grill????

If so how does it work???

Since I now can't get to the choke plate of the burner to light the burners I have to come up with another train of a thought! I have heard horror stories of someone reaching inside the chamber to light a burner. IE, burned arm hair, singed eyebrows and one case where the guy said it sent him across the room and when his ears quit ringing he realized he no longer had eyebrow or mustache! :what!::cursing: So that kind of makes me leary of that way of lighting the burners!

So how do you light your forge and do you have any suggestions on this one???

Last edited: