Josh Dabney

Moderator

Heya Dogs !

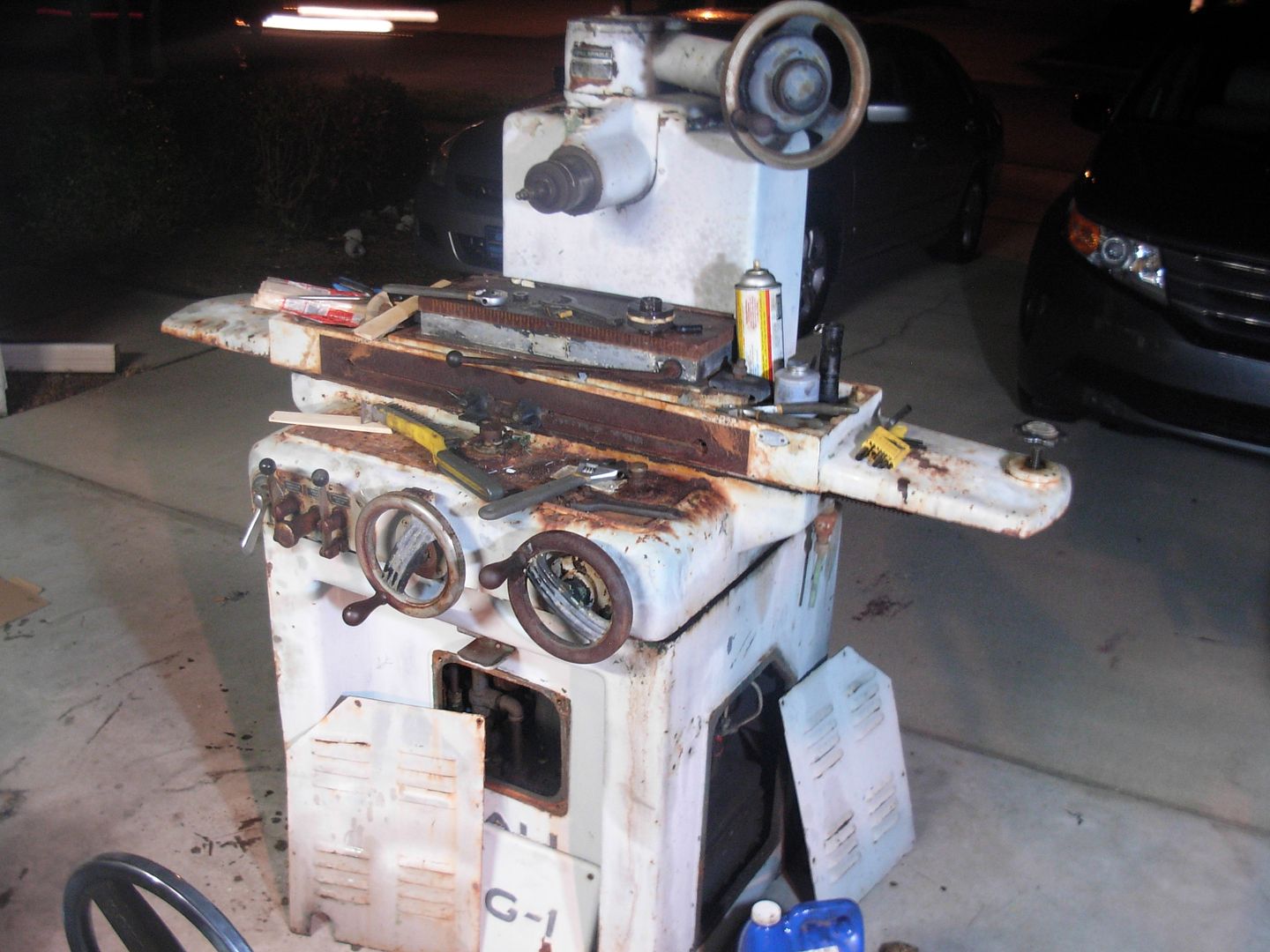

This has been in the works for a few weeks now but I've finally got the newest addition to the shop transported home so I thought I'd share.

She's an early DoAll G-1 6x18 with a fully automatic hydraulic table.

I've been FLAT broke do to the purchase but I got her for and song paid cash on the spot. A few cashless weeks is a small burden to bare for such a cool old machine. A friend of the seller even took care of the moving with a nice sized Bobcat with a boom attachment on it. We settled on a REDICULOUSLY low price of $200. The fella just wanted to see this old girl get a good home and not end up being sold for scrap so we made the deal.

The seller got this grinder in a package deal along with a beautiful Bridgeport mill but never even put the grinder under power. He had it stored outside for an unknown number of years so rust is significant but the table and column all move through their movement ranges. The On/Off switches and reset buttons are all rusted solid, the chuck is broken, and no test run at all but for the price I figured I'd get it even if it ends up needing a major overhaul to be functional.

Here She is in the shop :happy:

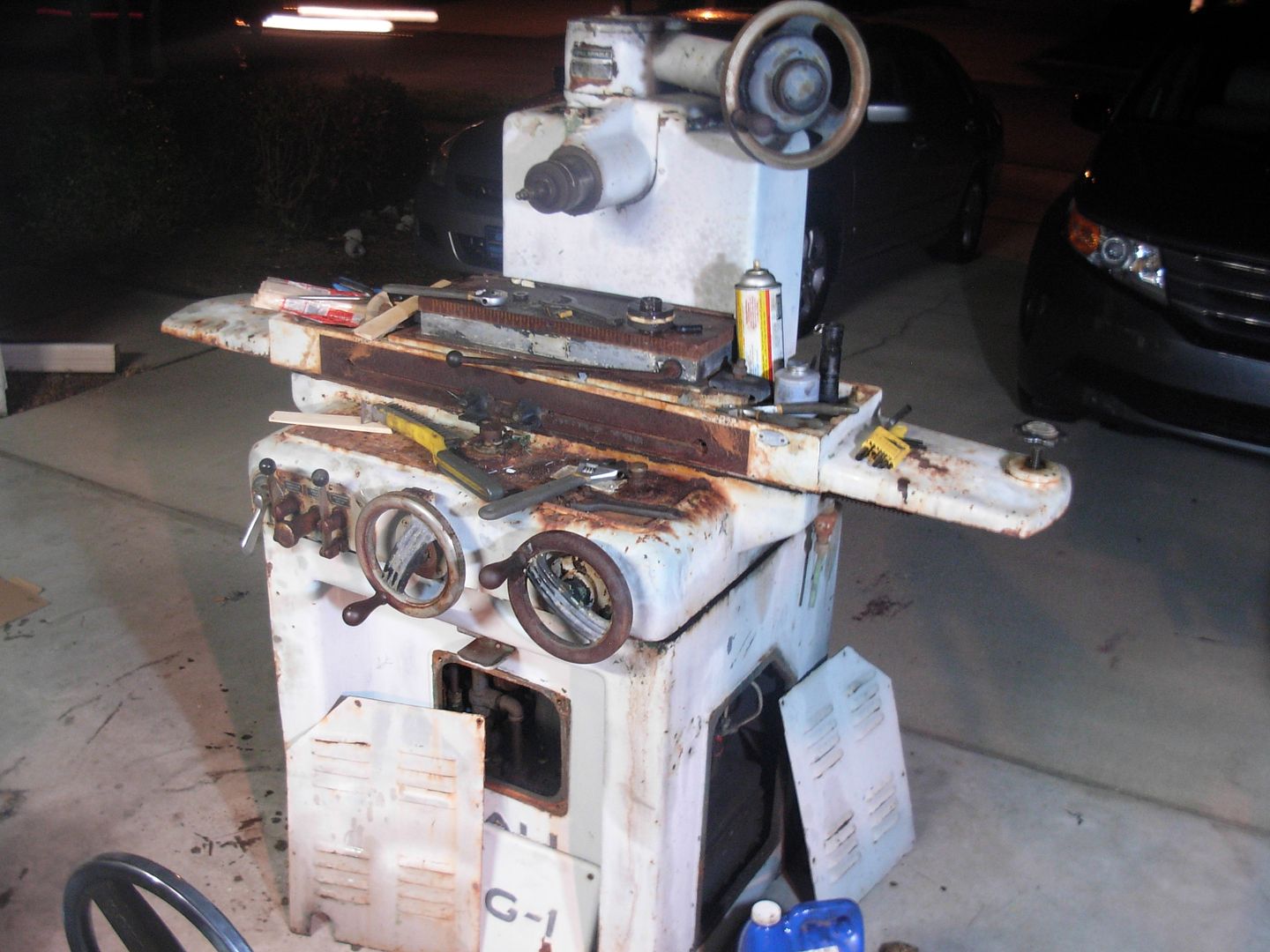

I spent a couple hours tinkering with it last night. I have spent the last couple weeks mentally preparing for the worst imagining every screw and bolt rusted tight with nightmarish work to free them all.

Rusted and painted over for sure but I managed to break them all free without even stripping a head.

Got the stone guard removed without any real grief and I managed to remove the stone adapter from the spindle taper with a bit of effort. The spindle turns smoothly with ZERO noticible play in any direction so I've got my fingers crossed that the spindle bearings are in good shape. Angular contact bearing are very exspensive so I'd rather not have to open up the spindle unless it's absolutely necessary. Replacement bearing are still available though so a spindle rebuild could be done if mandatory.

The spindle adapter is rusted solid so I may have to give an attempt at electrolosis rust removal on that and some other smaller rusted parts like the switch covers. Spindle adapters are availible of needed so it's a matter of attempting to fix what I've got or aquiring a new adapter.

The machine has an automatic oiler built in to lubricate the table ways but it is powered by the hydraulic unit so I manually lubricated the ways with way oil so she won't be sliding on dry ways until I get her powered up.

Having all the access panels on the cabinet removed I don't see anything thats raising any alarm flags inside the cabinet. The pump & motor shaft spin freely and all the hydraulic lines are piped in iron pipe. The oiler lines are copper with no kinks or dents that I could see. The electrical all seems pretty straight forward and all wire is run inside flexible conduit. It's a little oily inside the cabinet but there's no puddles or indication of leaks anywhere. Also no evidence of bugs, rats, snakes, or any other critters taking up residence inside or evidence of shoddy repair work so in a nutshell things are looking quite good :1971_dancing_dog:

I was anticipating that all the seals in the hydraulic cylinders would be dry rotted but the system appears to be air tight still. When you manually move the table and the cylinder compresses you can hear air bubbles being blown back into the hydraulic tank. Won't know anything for sure until she's pressurized and running under her own power but I'm thinking the air being forced into the tank is a good sign.

Planning to do a mild resto on her so here's my rough plan

-finish going over her

-wire up a plug and then mechanical test

-Fix anything broken and confirm the auto oiler is functioning properly

-Strip off the rust and paint and re-paint Not sure what to paint her with. Was thinking about Epoxy Garage floor paint for it's toughness but now thinking rattle can for easy of application and touch-up. Suggestions would be appreciated

-Build a belt conversion unit. Plan to go all out for precise tracking in a three wheel set-up using Beaumont wheels.

-Not sure about the Chuck yet. It's broken but it is a Suburban fine pole chuck so I'll check into sending it out for repair vs buying a new chuck. If it seems worth it to go new price wise I'll probably tear into this chuck and attempt to fix it myself first.

It'll probably take me awhile to get this girl ready for some grinding action but she'll be a dandy when I'm done with her.

Take care Dogs !

-Josh

This has been in the works for a few weeks now but I've finally got the newest addition to the shop transported home so I thought I'd share.

She's an early DoAll G-1 6x18 with a fully automatic hydraulic table.

I've been FLAT broke do to the purchase but I got her for and song paid cash on the spot. A few cashless weeks is a small burden to bare for such a cool old machine. A friend of the seller even took care of the moving with a nice sized Bobcat with a boom attachment on it. We settled on a REDICULOUSLY low price of $200. The fella just wanted to see this old girl get a good home and not end up being sold for scrap so we made the deal.

The seller got this grinder in a package deal along with a beautiful Bridgeport mill but never even put the grinder under power. He had it stored outside for an unknown number of years so rust is significant but the table and column all move through their movement ranges. The On/Off switches and reset buttons are all rusted solid, the chuck is broken, and no test run at all but for the price I figured I'd get it even if it ends up needing a major overhaul to be functional.

Here She is in the shop :happy:

I spent a couple hours tinkering with it last night. I have spent the last couple weeks mentally preparing for the worst imagining every screw and bolt rusted tight with nightmarish work to free them all.

Rusted and painted over for sure but I managed to break them all free without even stripping a head.

Got the stone guard removed without any real grief and I managed to remove the stone adapter from the spindle taper with a bit of effort. The spindle turns smoothly with ZERO noticible play in any direction so I've got my fingers crossed that the spindle bearings are in good shape. Angular contact bearing are very exspensive so I'd rather not have to open up the spindle unless it's absolutely necessary. Replacement bearing are still available though so a spindle rebuild could be done if mandatory.

The spindle adapter is rusted solid so I may have to give an attempt at electrolosis rust removal on that and some other smaller rusted parts like the switch covers. Spindle adapters are availible of needed so it's a matter of attempting to fix what I've got or aquiring a new adapter.

The machine has an automatic oiler built in to lubricate the table ways but it is powered by the hydraulic unit so I manually lubricated the ways with way oil so she won't be sliding on dry ways until I get her powered up.

Having all the access panels on the cabinet removed I don't see anything thats raising any alarm flags inside the cabinet. The pump & motor shaft spin freely and all the hydraulic lines are piped in iron pipe. The oiler lines are copper with no kinks or dents that I could see. The electrical all seems pretty straight forward and all wire is run inside flexible conduit. It's a little oily inside the cabinet but there's no puddles or indication of leaks anywhere. Also no evidence of bugs, rats, snakes, or any other critters taking up residence inside or evidence of shoddy repair work so in a nutshell things are looking quite good :1971_dancing_dog:

I was anticipating that all the seals in the hydraulic cylinders would be dry rotted but the system appears to be air tight still. When you manually move the table and the cylinder compresses you can hear air bubbles being blown back into the hydraulic tank. Won't know anything for sure until she's pressurized and running under her own power but I'm thinking the air being forced into the tank is a good sign.

Planning to do a mild resto on her so here's my rough plan

-finish going over her

-wire up a plug and then mechanical test

-Fix anything broken and confirm the auto oiler is functioning properly

-Strip off the rust and paint and re-paint Not sure what to paint her with. Was thinking about Epoxy Garage floor paint for it's toughness but now thinking rattle can for easy of application and touch-up. Suggestions would be appreciated

-Build a belt conversion unit. Plan to go all out for precise tracking in a three wheel set-up using Beaumont wheels.

-Not sure about the Chuck yet. It's broken but it is a Suburban fine pole chuck so I'll check into sending it out for repair vs buying a new chuck. If it seems worth it to go new price wise I'll probably tear into this chuck and attempt to fix it myself first.

It'll probably take me awhile to get this girl ready for some grinding action but she'll be a dandy when I'm done with her.

Take care Dogs !

-Josh