Lore

Member

I just unboxed my new Variable Speed KMG-10 and I'm having a little trouble figuring out the electrical wiring.

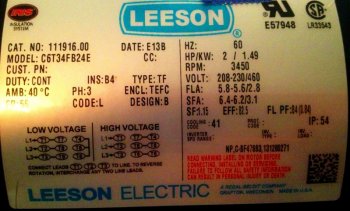

I have the 2 hp motor but I will be running it on standard 110 until my shop is wired for 220.

The site says the motor will run at a max of 1.5 hp when connected to standard 110.

I've followed the diagrams and made most of the connections but there is 1 thing I'm unsure about and I'm afraid to just take a wild guess and risk burning something out.

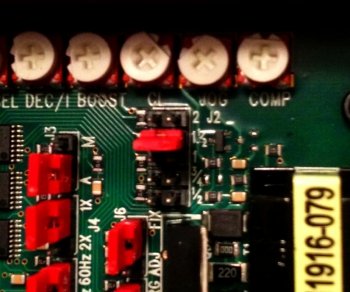

The KMG site says to "Set the motor Horse Power jumper for the appropriate motor size."

My motor size is 2 hp but since I'm running it on standard 110 the motor will only produce a max of 1.5 hp.

So, do I set the jumper at 1.5 or 2?

The photo below shows that the little red plastic cap is in the "1.5" jumper. Do I leave it there or do I move the red plastic cap to the jumper marked "2"?

I tried to call Beaumont Metalworks but I guess they're closed for Labor Day Weekend. I really don't want to stare at this grinder for the next 2 days until I can get them on the phone. I want to start grinding some metal! Help!

I have the 2 hp motor but I will be running it on standard 110 until my shop is wired for 220.

The site says the motor will run at a max of 1.5 hp when connected to standard 110.

I've followed the diagrams and made most of the connections but there is 1 thing I'm unsure about and I'm afraid to just take a wild guess and risk burning something out.

The KMG site says to "Set the motor Horse Power jumper for the appropriate motor size."

My motor size is 2 hp but since I'm running it on standard 110 the motor will only produce a max of 1.5 hp.

So, do I set the jumper at 1.5 or 2?

The photo below shows that the little red plastic cap is in the "1.5" jumper. Do I leave it there or do I move the red plastic cap to the jumper marked "2"?

I tried to call Beaumont Metalworks but I guess they're closed for Labor Day Weekend. I really don't want to stare at this grinder for the next 2 days until I can get them on the phone. I want to start grinding some metal! Help!