wmhammond

Well-Known Member

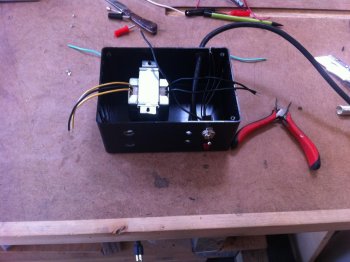

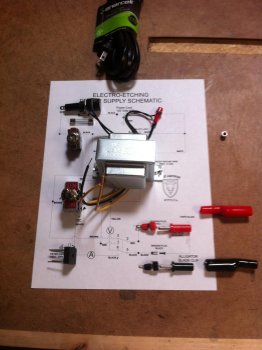

I just got back from visiting 4 different Radio Shack stores. I live in Las Cruces, NM and we have 4 Radio Shack stores here. Why? Well I'm going to try and build Ernie Grospitch"s Etching Power Supply. I have absolutely no experience building electrical gizmos and I can't read Ernie's wiring diagram but I can solder. So, why did I go to 4 Radio Shacks? Took all 4 to complete the parts list. I printed Ernie's parts list and took off. First store had about half of what I needed. Got the fuse, Fuse Holder, Transformer, Rectifier, Banana Plugs, Banana Jacks and the Neon Lamp. First store didn't have either of the switches because they have been discontinued but the guy told me that most of the stores still have some so I went to the next one - no luck, went to the next one - no luck (may have to go to El Paso).

Should stop here and explain why I wanted to have these exact switches. I'm sure a lot of you guys are laughing at me because I could have substituted any switch for these. My common sense tells me that that is logical and correct, however, like I said above, I know absolutely nothing about electrical stuff and when I start something like this, that I know nothing about, I follow the instructions to the letter because I know it won't work the first time and I won't know it those substituted switches are the problem or not. This way, I know it ain't the components, it's the maker. Anyway, went to the last Radio Shack in town and BINGO, they had both switches. In addition I purchased the Alligator Clips, a power cord and a Project Box to put it all in. I now have the exact parts that Ernie listed, Total money spent: $58.79, Total time spent: 2 hours 15 minutes. Here is all the stuff:..............

Oh, and by the way, that little chrome thing in the upper right of the third picture is a little part that fell out of one (I don't know which one) of the packages when I opened them. With that little hic-up this project is starting exactly like all my others. More later........

Should stop here and explain why I wanted to have these exact switches. I'm sure a lot of you guys are laughing at me because I could have substituted any switch for these. My common sense tells me that that is logical and correct, however, like I said above, I know absolutely nothing about electrical stuff and when I start something like this, that I know nothing about, I follow the instructions to the letter because I know it won't work the first time and I won't know it those substituted switches are the problem or not. This way, I know it ain't the components, it's the maker. Anyway, went to the last Radio Shack in town and BINGO, they had both switches. In addition I purchased the Alligator Clips, a power cord and a Project Box to put it all in. I now have the exact parts that Ernie listed, Total money spent: $58.79, Total time spent: 2 hours 15 minutes. Here is all the stuff:..............

Oh, and by the way, that little chrome thing in the upper right of the third picture is a little part that fell out of one (I don't know which one) of the packages when I opened them. With that little hic-up this project is starting exactly like all my others. More later........