You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The start of something great! (WIP)

- Thread starter Daniel Macina

- Start date

Daniel Macina

Well-Known Member

Daniel Macina

Well-Known Member

Daniel Macina

Well-Known Member

Use more oil while drilling that 1018 than you think need. CR 1018 cuts beautifully but will gall if there is not enough lube.

Yessir! Learned that the hard way on a few projects! Lol

Daniel Macina

Well-Known Member

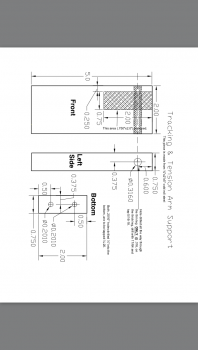

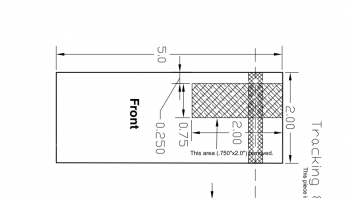

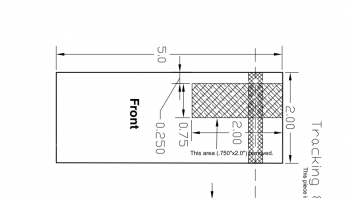

Quick question. This is the upright that holds the tracking arm. It looks to me like on the plans like there should be 3/4" of steel on the right side and 1/4" steel on the left and that the slot should be 3/4" across the only problem is if I remove the metal where it says it would be a 1" slot? What am I missing. Am I reading the blueprints wrong?

Kevin Zito

KNIFE MAKER

Shouldn’t there be a 1 inch piece of steel on the right side and not .75?

Daniel Macina

Well-Known Member

Shouldn’t there be a 1 inch piece of steel on the right side and not .75?

I'm sure you are correct I just wanted to make sure I wasn't missing something. Thank you sir!

Kevin Zito

KNIFE MAKER

Wait... don’t go by what I’m saying!!!! I have no idea what I’m talking about. I’d definitely wait to hear from some of the others lol.I'm sure you are correct I just wanted to make sure I wasn't missing something. Thank you sir!

Ty Adams

KNIFE MAKER

I would need to see the whole drawing, but it looks like the 3/4" might be referring to the space you need to remove. There should be a spot that shows hole size in the lower right hand corner of the drawing. Every engineer draws things differently. If I were you leave the .250 on both sides and cut it out later if need be.

Daniel Macina

Well-Known Member

C Craft

Well-Known Member

Daniel I had to go back and pull up my copy of the plans. That is correct the piece is 2" wide.

.025/ or 1/4" over from the left

then remove 0.75 or 3/4"

that leaves 1" on the right side

This is cut this way to align the tracking arm correctly with the tracking pivot and wheel

.025/ or 1/4" over from the left

then remove 0.75 or 3/4"

that leaves 1" on the right side

This is cut this way to align the tracking arm correctly with the tracking pivot and wheel

Daniel Macina

Well-Known Member

Daniel I had to go back and pull up my copy of the plans. That is correct the piece is 2" wide.

.025/ or 1/4" over from the left

then remove 0.75 or 3/4"

that leaves 1" on the right side

This is cut this way to align the tracking arm correctly with the tracking pivot and wheel

Ahha! Makes sense I was looking at it all wrong. Thanks. You guys are life savers!

Daniel Macina

Well-Known Member

I knew it had to be cut a certain way to line up with everything else. Glad I checked.

C Craft

Well-Known Member

Just out of curiosity, where did you get the plans from? They seem to be well drawn.

Here you go! http://www.knifehelp.net/media/docs/GrinderPlans.pdf

Daniel you can see on those plans, page 4 of 7 a shot of that piece! Having said all that, the 1/4" does not sound like much. So went out and measured mine a minute ago and I increased the thickness on the left side to 1/2" then I took out the 3/4" leaving 3/4" on the right side!!I knew it had to be cut a certain way to line up with everything else. Glad I checked.

Making the drive pulley, the tracking pulley and your (working wheel, or platen or small wheel) the line up of all three is accomplished by coming square off of the base and then each pulley is set to whatever specific measurement off of that square line you decide to set them at.

You will have a little to play with working off of your working wheel and the tracking pulley, the drive pulley, so don't sweat if you want to go to 1/2", it just means those other two pulleys will have to bumped out another 1/4" to accommodate for the added thickness!!

Biggest think about building a grinder that works is all about square and true!! Use sharp bits so your holes don't begin to wander and make sure when you set a piece it is square to the base!! Oh and be prepared because you are going to break some taps. Unless you have better luck than I do. By the end of the build I got real good at getting a broken tap out of the hole!!!

On that yoke I drilled and went to a bolt and a locking nut, before I cut out the 3/4" in the center. To me it was just easier to keep it all true by doing that way! Plus it saved me having to tap it!! You can use your discretion to vary slightly from the plans, you just have to understand where you can and can't do that!

Daniel Macina

Well-Known Member

All right time to start on the idler arm support. You can faintly see where I scribed the lines and where the metal needs to be removed. I drilled a hole roughly in the middle of this To where I can saw a little behind the lines and be able to rotate the saw blade in the hole. Once I get the majority of the metal out I will switch to Files to clean it up completely. I was going to file the whole thing but the thought of filing 3/4" thick steel 2" deep didn't really appeal to me.