REK Knives

Well-Known Member

I have never wanted to vent air outside because my shop is heated and cooled... and in order to do that you have to have some way for fresh outside air to come in your shop, which wouldn't be heated or cooled without a heat exchanger (from what I've been told)

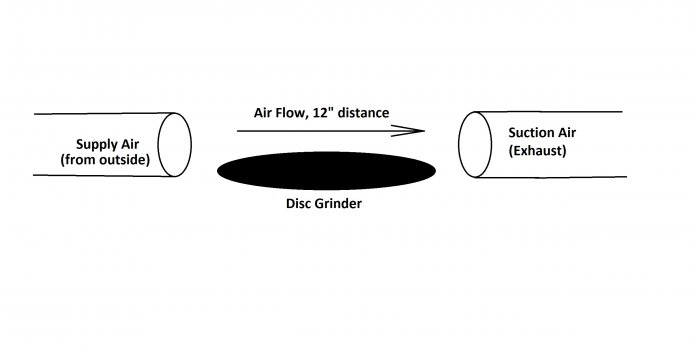

So I though I was reduced to getting a traditional filter set up. But I was talking with my FIL and he had a good point... what if you had a supply line (from outside, fresh air) and an exhaust line (the blower end, that would pump air out of your shop). You would then position 2 hoses at each station... a fresh air hose and an exhaust air hose. This way the air that is not climate controlled would only be traveling a short distance and not heating/cooling your entire shop.

This would eliminate the need for a large footprint for a traditional filter, and it would also lower costs significantly.

Has anyone actually done it in this way? Does this work? and if so, how well does it work? I know a lot of guys suck the air out of their shop but their shop isn't heated or cooled.

So I though I was reduced to getting a traditional filter set up. But I was talking with my FIL and he had a good point... what if you had a supply line (from outside, fresh air) and an exhaust line (the blower end, that would pump air out of your shop). You would then position 2 hoses at each station... a fresh air hose and an exhaust air hose. This way the air that is not climate controlled would only be traveling a short distance and not heating/cooling your entire shop.

This would eliminate the need for a large footprint for a traditional filter, and it would also lower costs significantly.

Has anyone actually done it in this way? Does this work? and if so, how well does it work? I know a lot of guys suck the air out of their shop but their shop isn't heated or cooled.