antigoth24

Well-Known Member

I'm sure there are several fans of the show Vikings on here (myself included) which was where I drew some inspiration for this seax. I still have to complete the sheath and will post final photos at that point, but I liked it so much I couldn't resist sharing it on here. After doing a ton a production work last month I figured it was time for a skill building project, and decided on attempting a wolf's tooth pattern seax. I then decided to make it more complicated by doing a seven bar composite seax (again for those that don't know I don't have a press or power hammer and this is all done with my 3 1/2 lb forging hammer).

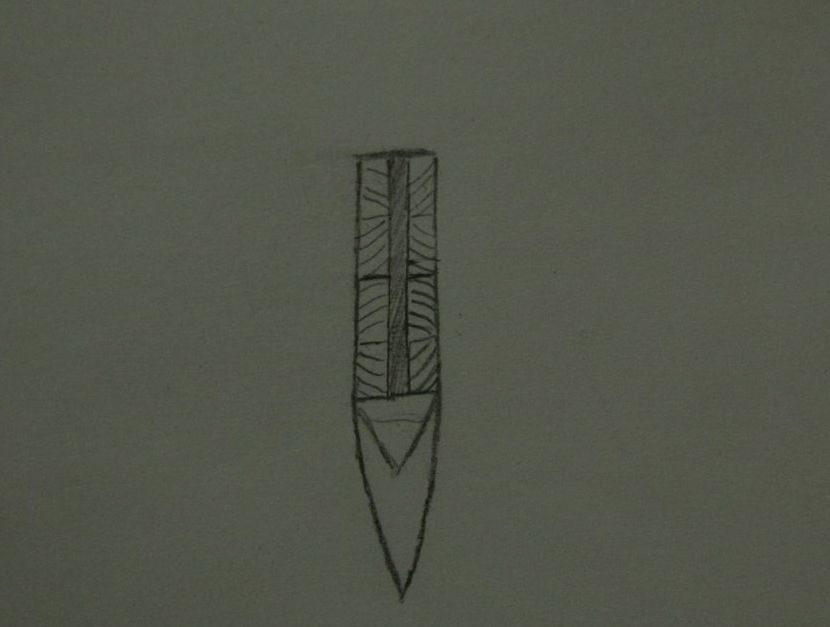

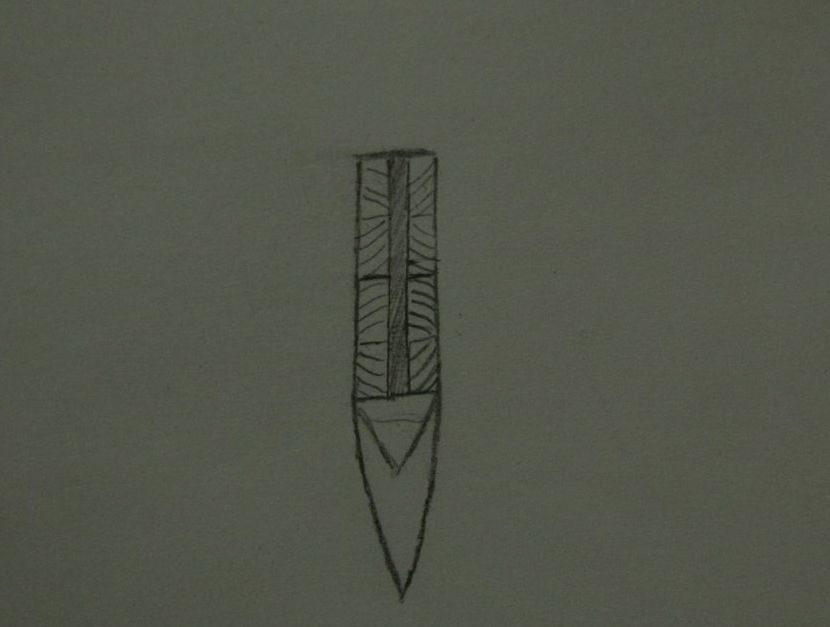

So just because it is a weird construction method here is a picture of what I mean by seven bar composite. The edge geometry on this drawing isn't to scale just a rough guideline for following while forging.

The vertical bar is the central core of wrought iron, while each of the four bars (two per side of the wrought iron) are 10 layers of 15n20 and 1080. These four bars and the wrought iron core are welded into a billet which is then welded to the edge billet which is made of two billets. The teeth are 1095 and the back bar is L6, 1080, and wrought iron.

The teeth and back bar contain about 20 or so layers all together and forged together well, although I ended up not having enough tooth material and lost a couple of teeth in the end knife towards the back edge which was a real bummer, but lesson learned and the edge hardened just fine so no problems there.

Because I do my pattern welding by hand I often get creative about how I assemble billets to make things easier on myself. In this case making 1/2 wide x 3/4 inch thick, x 13 inch long billets. This next photo shows what will become the spine (five bar composite) and the edge billet.

Then this was where is got tricky and why I lost a couple teeth, welding on edge at 1/4 inch thickness for a 3 inch wide billet can be tricky and it did fight me for a bit.

All told it took me about eight hours of forge work from start to finish to forge this blade. But eventually it all came together and after ruining a beautiful piece of 6,000 year old bog oak and then spending another $60 on some top shelf black ash burl I ended up with a size-able seax. I haven't taken the final measurements yet but it is sitting right around 15/16 inches overall length and the edge is about 1 3/4 wide at the widest with a 1/4 inch spine at the ferrule. The ferrule is carved bronze (a first for me and extremely basic) and then this beautiful piece of black ash burl. Over all I am very pleased with it and it was a great learning experience, with the sheath still to go.

I'll post pictures with the sheath when it is completed but thanks for looking and all comments are welcome.

Robert

So just because it is a weird construction method here is a picture of what I mean by seven bar composite. The edge geometry on this drawing isn't to scale just a rough guideline for following while forging.

The vertical bar is the central core of wrought iron, while each of the four bars (two per side of the wrought iron) are 10 layers of 15n20 and 1080. These four bars and the wrought iron core are welded into a billet which is then welded to the edge billet which is made of two billets. The teeth are 1095 and the back bar is L6, 1080, and wrought iron.

The teeth and back bar contain about 20 or so layers all together and forged together well, although I ended up not having enough tooth material and lost a couple of teeth in the end knife towards the back edge which was a real bummer, but lesson learned and the edge hardened just fine so no problems there.

Because I do my pattern welding by hand I often get creative about how I assemble billets to make things easier on myself. In this case making 1/2 wide x 3/4 inch thick, x 13 inch long billets. This next photo shows what will become the spine (five bar composite) and the edge billet.

Then this was where is got tricky and why I lost a couple teeth, welding on edge at 1/4 inch thickness for a 3 inch wide billet can be tricky and it did fight me for a bit.

All told it took me about eight hours of forge work from start to finish to forge this blade. But eventually it all came together and after ruining a beautiful piece of 6,000 year old bog oak and then spending another $60 on some top shelf black ash burl I ended up with a size-able seax. I haven't taken the final measurements yet but it is sitting right around 15/16 inches overall length and the edge is about 1 3/4 wide at the widest with a 1/4 inch spine at the ferrule. The ferrule is carved bronze (a first for me and extremely basic) and then this beautiful piece of black ash burl. Over all I am very pleased with it and it was a great learning experience, with the sheath still to go.

I'll post pictures with the sheath when it is completed but thanks for looking and all comments are welcome.

Robert