Heikki

KNIFE MAKER

I'm about to heat treat my first knives in Magnacut and have a question for those of you that have already done so.

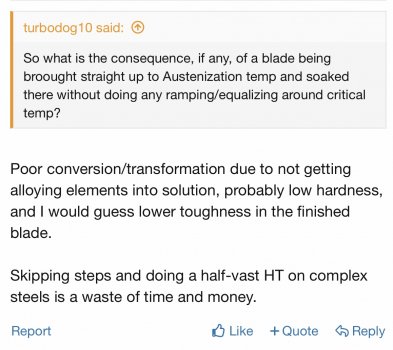

I've got the basic protocol for where I plan to start- 2050*F for 20 minutes, 350*F temper 2x2 hours. I'm trying to find out if you do an equalizing soak like you do for AEB-L, like 1550*-1600*F for 10 minutes before ramping up to aus temp. Does this steel require that or not? I'm not having any luck in my searching.

I've got the basic protocol for where I plan to start- 2050*F for 20 minutes, 350*F temper 2x2 hours. I'm trying to find out if you do an equalizing soak like you do for AEB-L, like 1550*-1600*F for 10 minutes before ramping up to aus temp. Does this steel require that or not? I'm not having any luck in my searching.