You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kirinite Pepper Jade bowie WIP

- Thread starter Mark Behnke

- Start date

Josh Dabney

Moderator

Loving the WIP Mark !

-Josh

-Josh

Mark Behnke

Well-Known Member

Brad, Josh

Thanks for looking in and following along, I'm getting excited as it's coming together, here's a little preview

Thanks for looking in and following along, I'm getting excited as it's coming together, here's a little preview

Mark Behnke

Well-Known Member

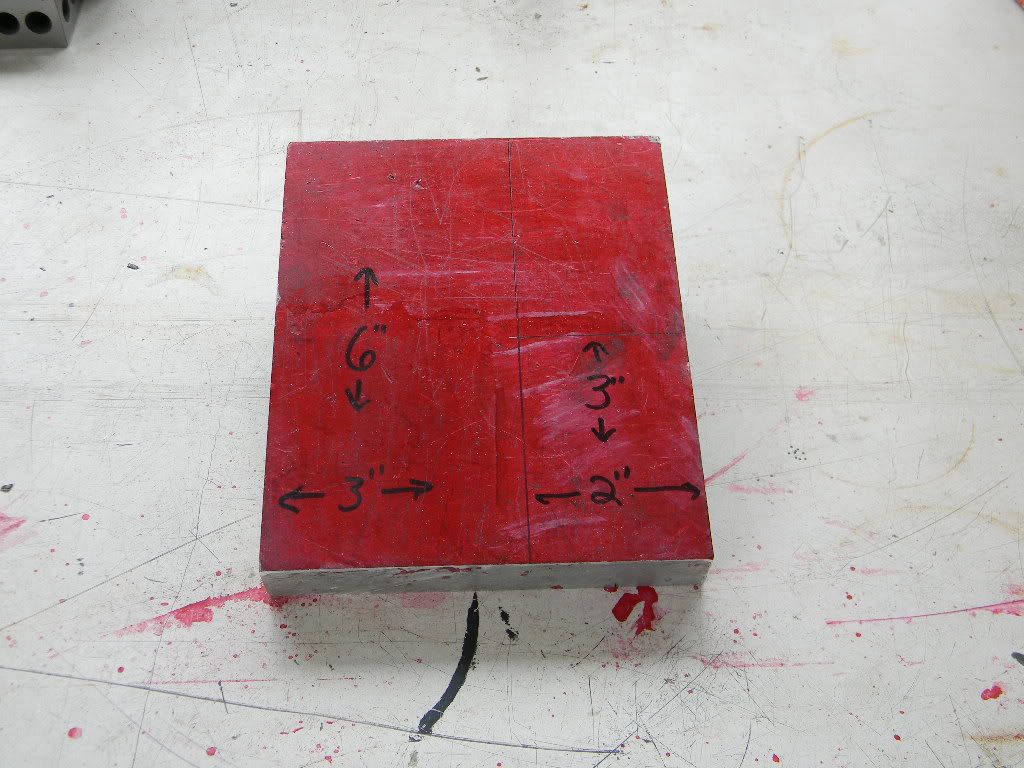

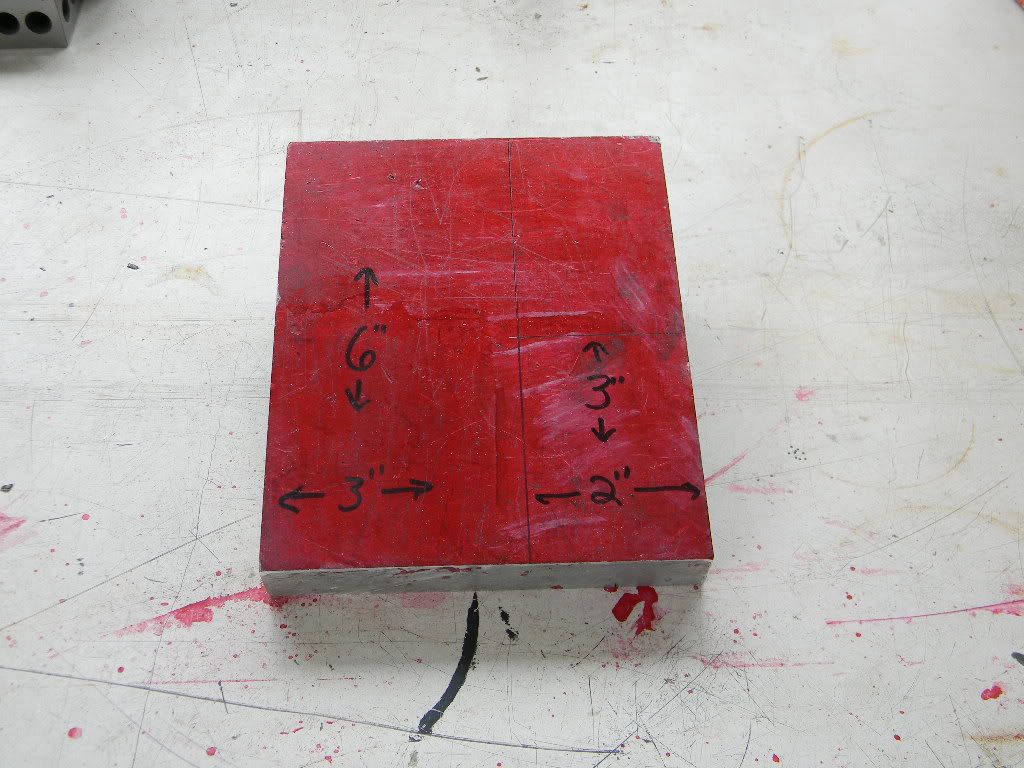

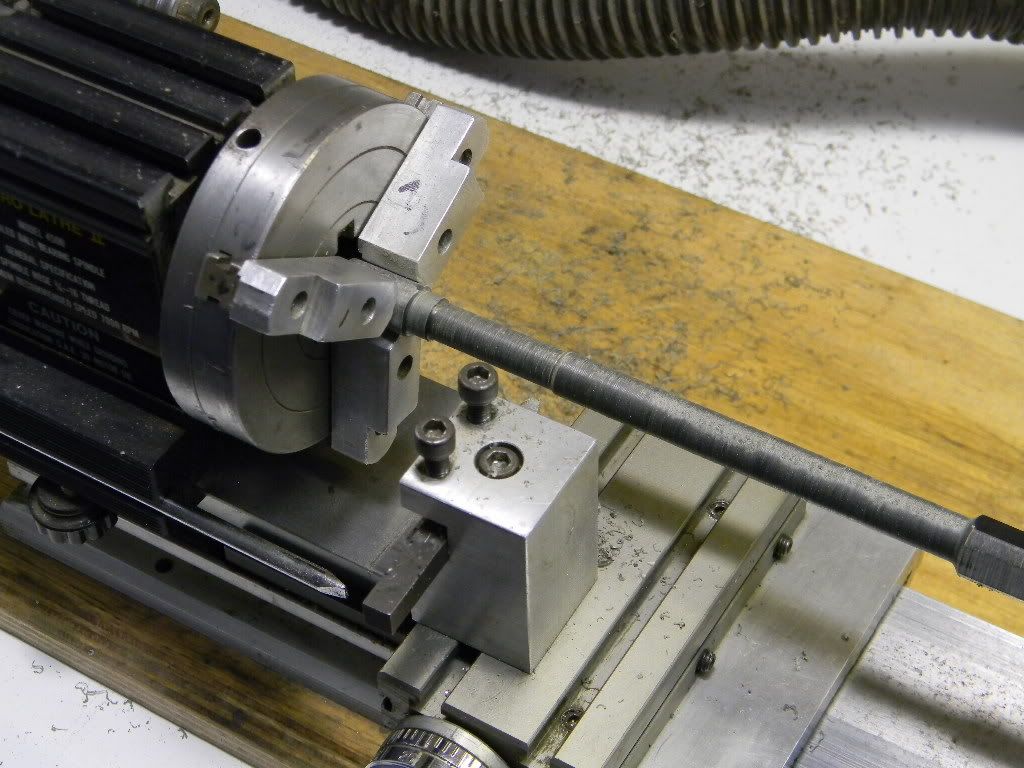

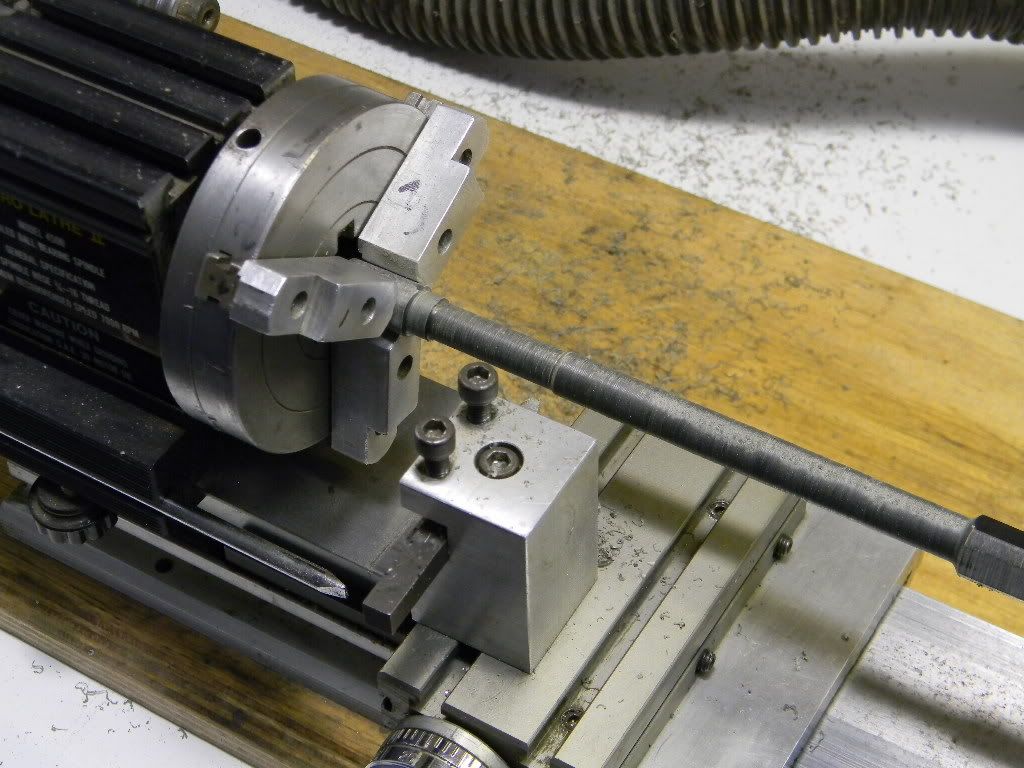

Tapered tang holding jig for handle holes.

That's what I need, simple to make, OK? I drilled the wrong size hole right off the bat, too large of course, then tried to tap with a tapmatic and stripped it.

The vertical piece will get a cap that clamps the recasso with the handle facing away. Then a little adjustable support stand to hold up the end of the handle.

The bottom plate will be held in the mill vise.

This is a design by Nick Wheeler .

That's what I need, simple to make, OK? I drilled the wrong size hole right off the bat, too large of course, then tried to tap with a tapmatic and stripped it.

The vertical piece will get a cap that clamps the recasso with the handle facing away. Then a little adjustable support stand to hold up the end of the handle.

The bottom plate will be held in the mill vise.

This is a design by Nick Wheeler .

Mark Behnke

Well-Known Member

J. Rosa, Thanks, Look what I did today http://knifedogs.com/showthread.php?26923-Tapered-Tang-Handle-Drilling-Jig

Liam, I'm peddling as fast as I can.

franklin, Thanks for the tip, I'm getting anxious too, lots of things to do still.

Liam, I'm peddling as fast as I can.

franklin, Thanks for the tip, I'm getting anxious too, lots of things to do still.

Mark Behnke

Well-Known Member

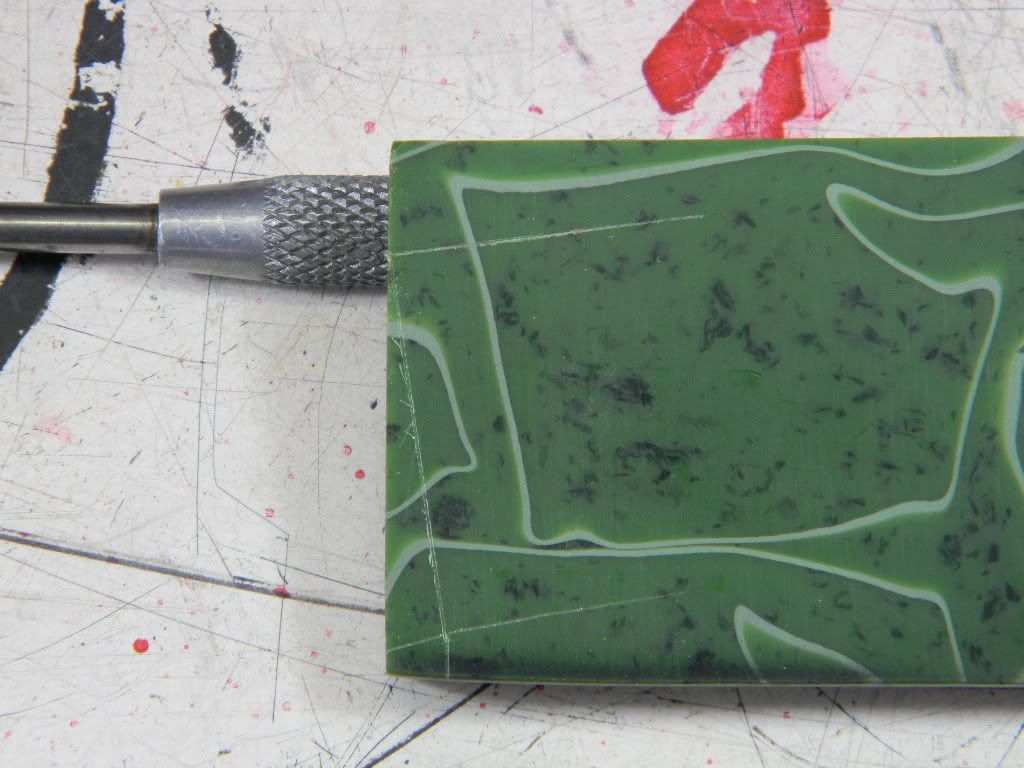

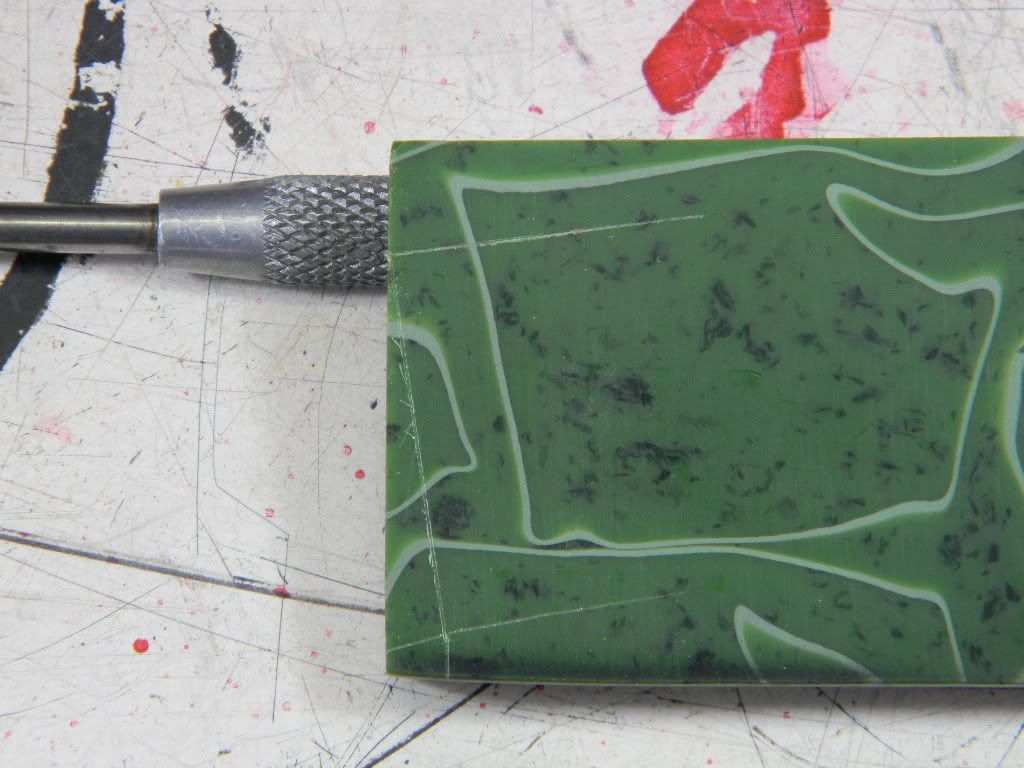

Worked on the blade, trying to get to 400g before heat treat. Drilled for guard pin and did a little profiling, rough cut the Kirinite.

The nib on the spine wasn't well thought out so slow going on the shaping, same with the guard.

Things go much faster when I have a definite plan and sketch, design as you go is slow, but sometimes I just can't visualize what I want.

I find a fine SS brush works very much better than a file card, also use it to clean my belts and discs.

The nib on the spine wasn't well thought out so slow going on the shaping, same with the guard.

Things go much faster when I have a definite plan and sketch, design as you go is slow, but sometimes I just can't visualize what I want.

I find a fine SS brush works very much better than a file card, also use it to clean my belts and discs.

Mark Behnke

Well-Known Member

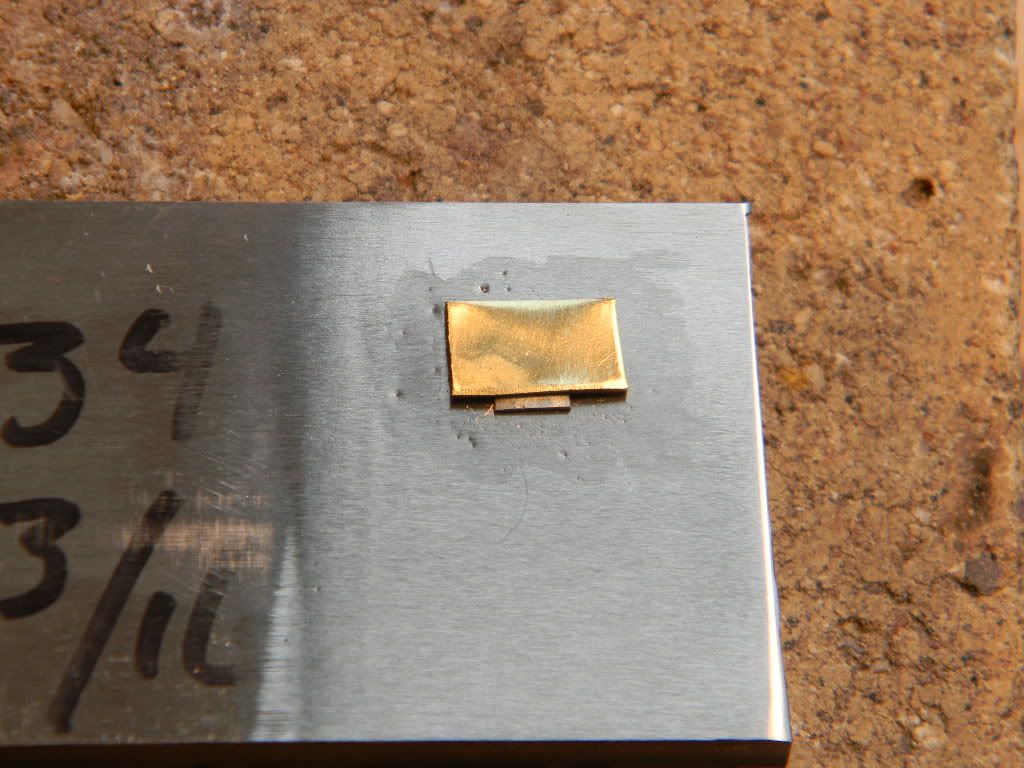

Worked on the guard today, lots of file work, but the brass is very soft and easy. This will be soldered , my first try at it. Not looking forward to the clean up.

I've soldered plumbing pipe, and hard silver, but never tried a guard.

I've soldered plumbing pipe, and hard silver, but never tried a guard.

Mark Behnke

Well-Known Member

Haven't been able to get in the shop as much as I'd like the last couple of days. Scratch chasing mostly and refining lines. These curves are killing me but I'm learning a lot. I tried checkering the spine with a 30 line per inch file, this is my second attempt, hopefully I can clean this up a bit.

Mark Behnke

Well-Known Member

I keep getting called away, but managed a couple hours. Cleaned up the checkering and hit it with some fine paper before the pic and a scratch I had worked hard on reappeared.

Scary, but it is Halloween.

Scary, but it is Halloween.

Mark Behnke

Well-Known Member

Thanks Boss

I've always wanted to engrave but this is probably as close as it's gonna get.

Heat treat day, 1900F 1/2 hr., plate quench, temper 450F 2 hrs.

The ovens are wax burn out kilns for lost wax casting The bigger one was $25.00 at a garage sale and the smaller one I just got in a lost wax casting package again from a garage sale. Need to get some bronze casting grain to try some guards.

Speaking of garage sales (we go every week end) found some file handles.

Waiting for the oven to reach temp. will post latter today.

The analog gauge will be replaced w/ digital

I've always wanted to engrave but this is probably as close as it's gonna get.

Heat treat day, 1900F 1/2 hr., plate quench, temper 450F 2 hrs.

The ovens are wax burn out kilns for lost wax casting The bigger one was $25.00 at a garage sale and the smaller one I just got in a lost wax casting package again from a garage sale. Need to get some bronze casting grain to try some guards.

Speaking of garage sales (we go every week end) found some file handles.

Waiting for the oven to reach temp. will post latter today.

The analog gauge will be replaced w/ digital

Mark Behnke

Well-Known Member

Completed the heat treat and while it was in the oven took the head off of the lathe and checked what I could, found out the jaws had to be reversed, not sure why one side is true and the other isn't.

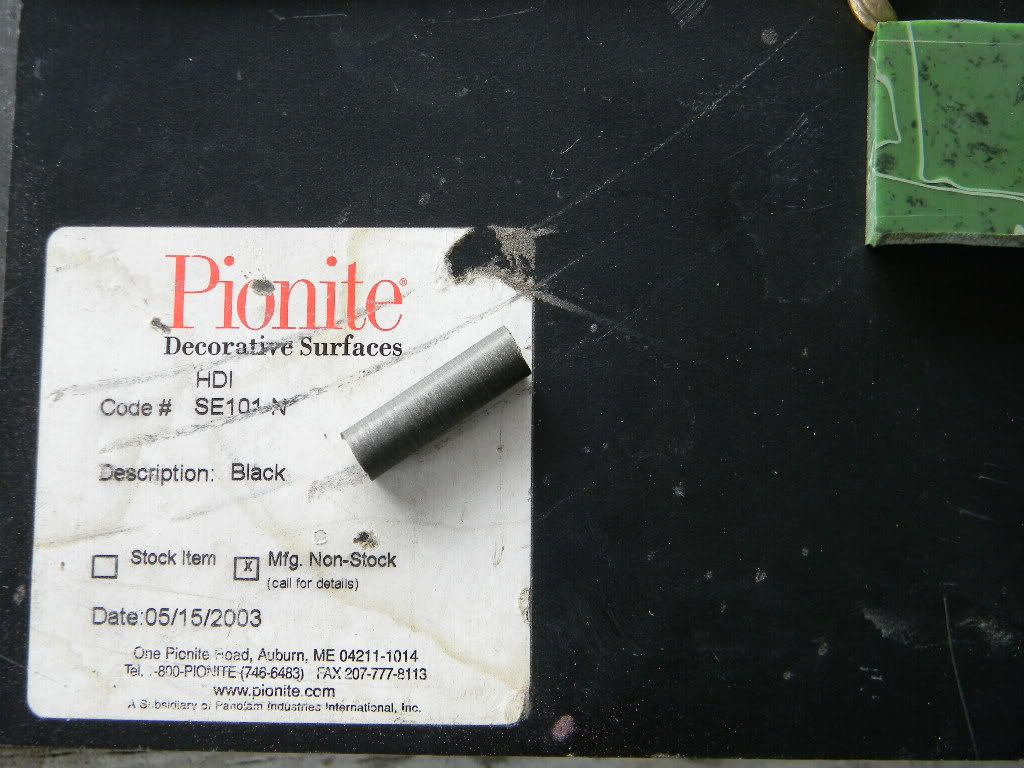

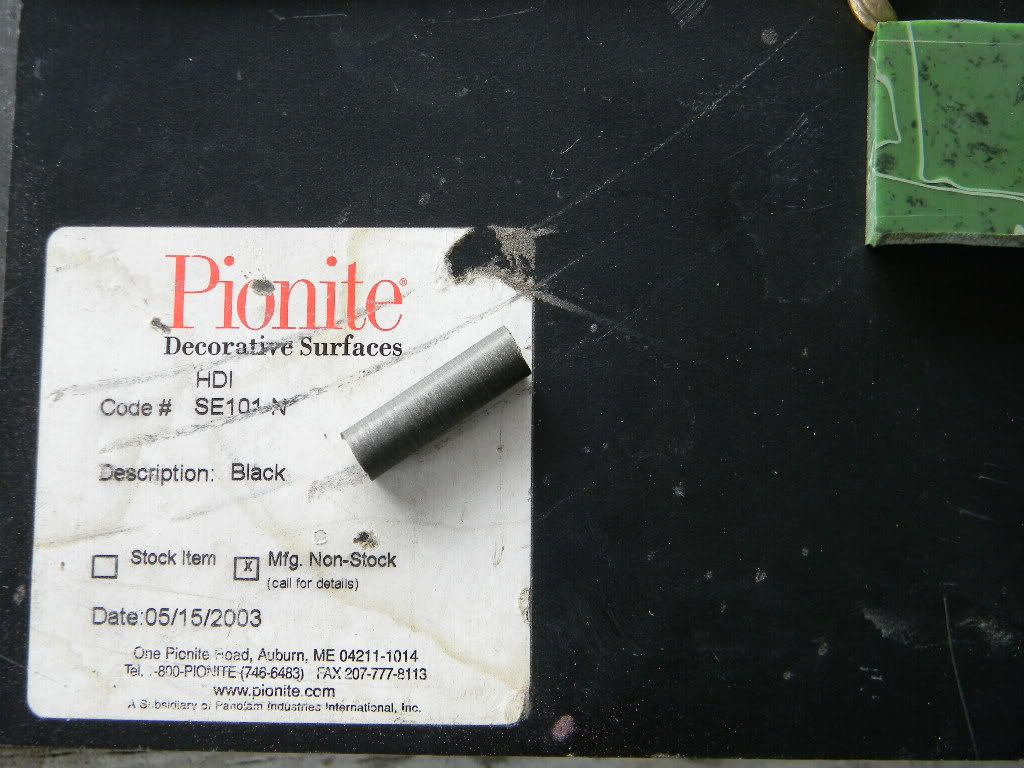

Got a 1' square sample of a counter top material good for chem. labs, very similar to paper micata, decided to use it. Turned the big pin and set up for the next one.

Need to clean up the blade then solder the guard, then the fun part, the handle. You really start to see what it's going to look like when the handle shaping starts.

Got a 1' square sample of a counter top material good for chem. labs, very similar to paper micata, decided to use it. Turned the big pin and set up for the next one.

Need to clean up the blade then solder the guard, then the fun part, the handle. You really start to see what it's going to look like when the handle shaping starts.

Mark Behnke

Well-Known Member

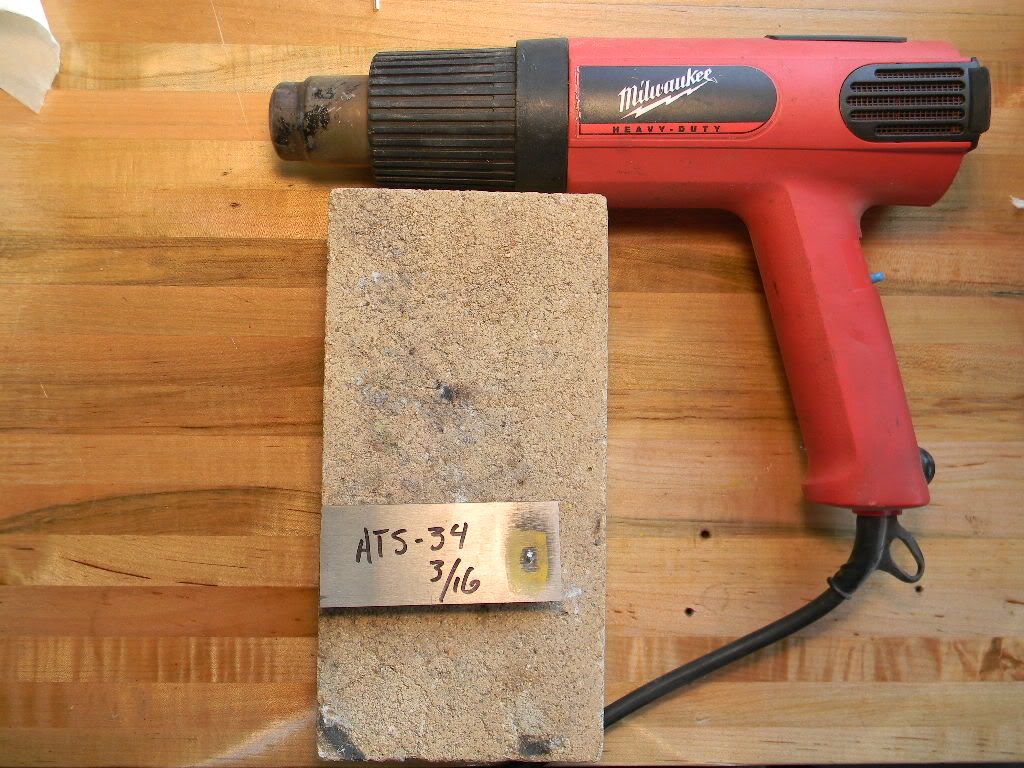

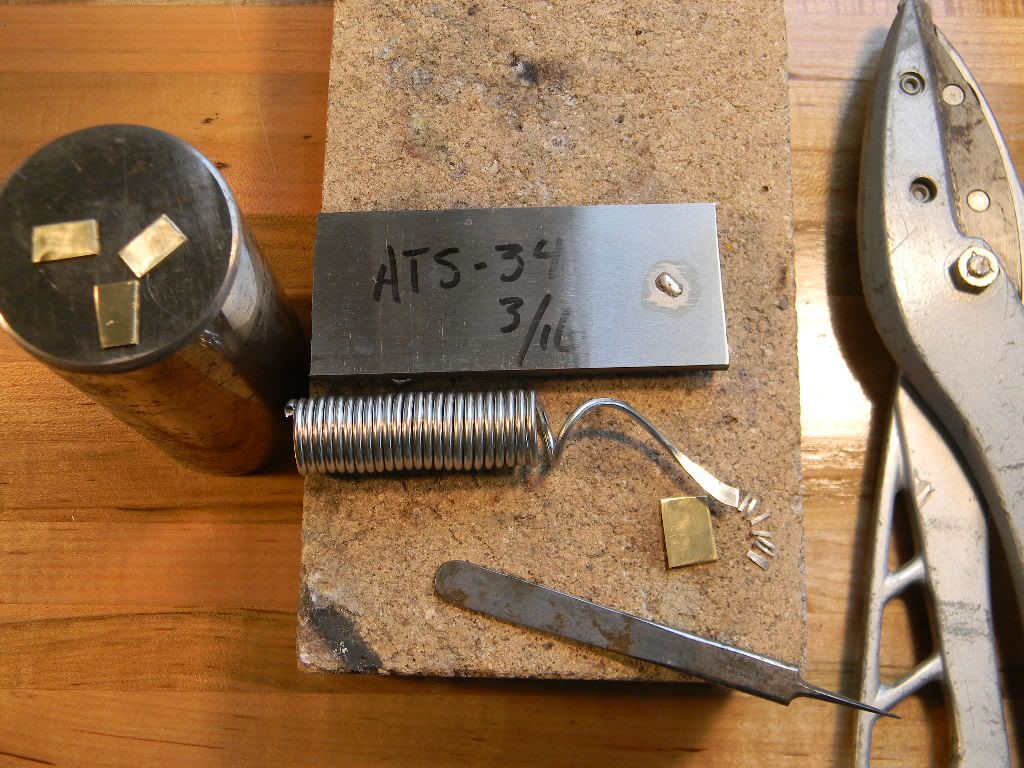

Solder time, oh boy.The Stay clean- Stay Bright solder and flux can't be found locally so I tried substitutes.

Sanded w/600g, alcohol wiped fluxed and painted a perimeter with yellow ochra to keep it in check. No flow using a heat gun. Tried the paste flux also to the left.

I pushed the solder around with a little titanium probe and noticed it did flow right under the bead of flux.

Tomorrow's another day, hopefully with more success, maybe a torch in the works and some Stay bright on order.

Sanded w/600g, alcohol wiped fluxed and painted a perimeter with yellow ochra to keep it in check. No flow using a heat gun. Tried the paste flux also to the left.

I pushed the solder around with a little titanium probe and noticed it did flow right under the bead of flux.

Tomorrow's another day, hopefully with more success, maybe a torch in the works and some Stay bright on order.

Brad Lilly

Moderator and Awards Boss

Looking good Mark.

Mark Behnke

Well-Known Member

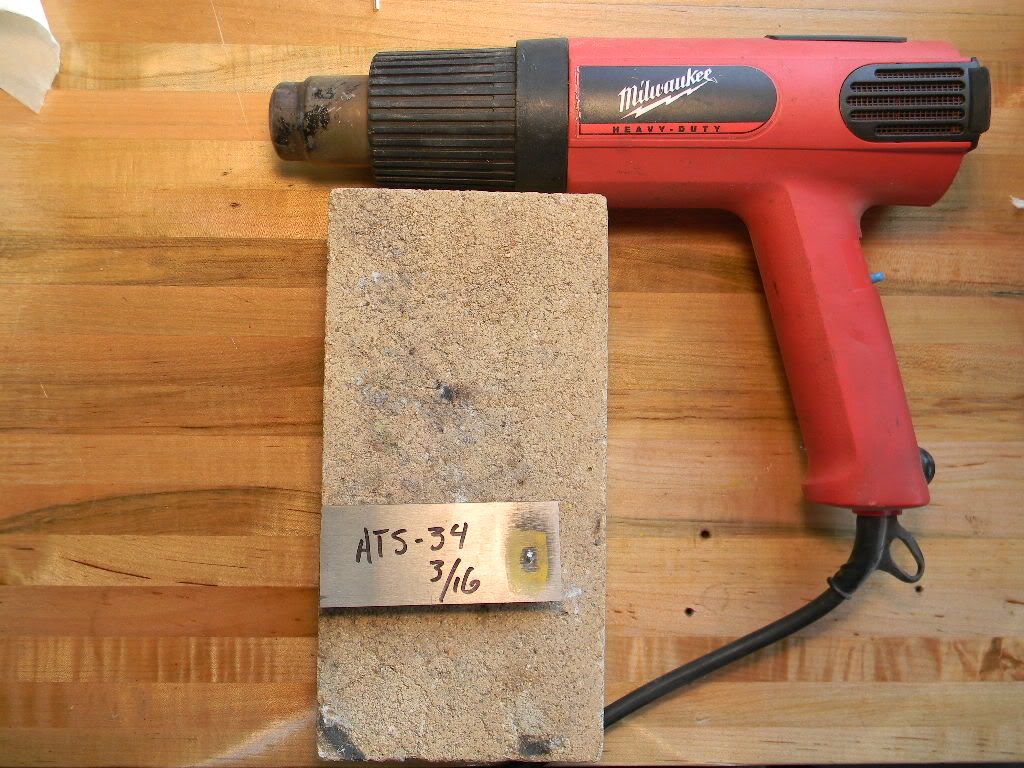

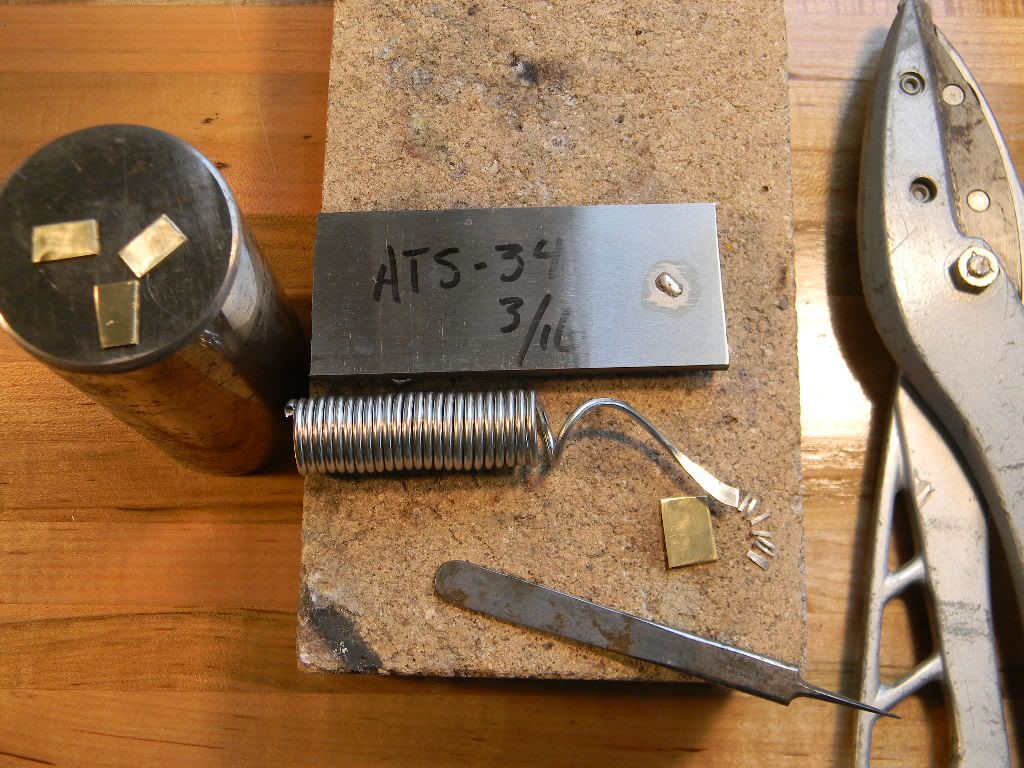

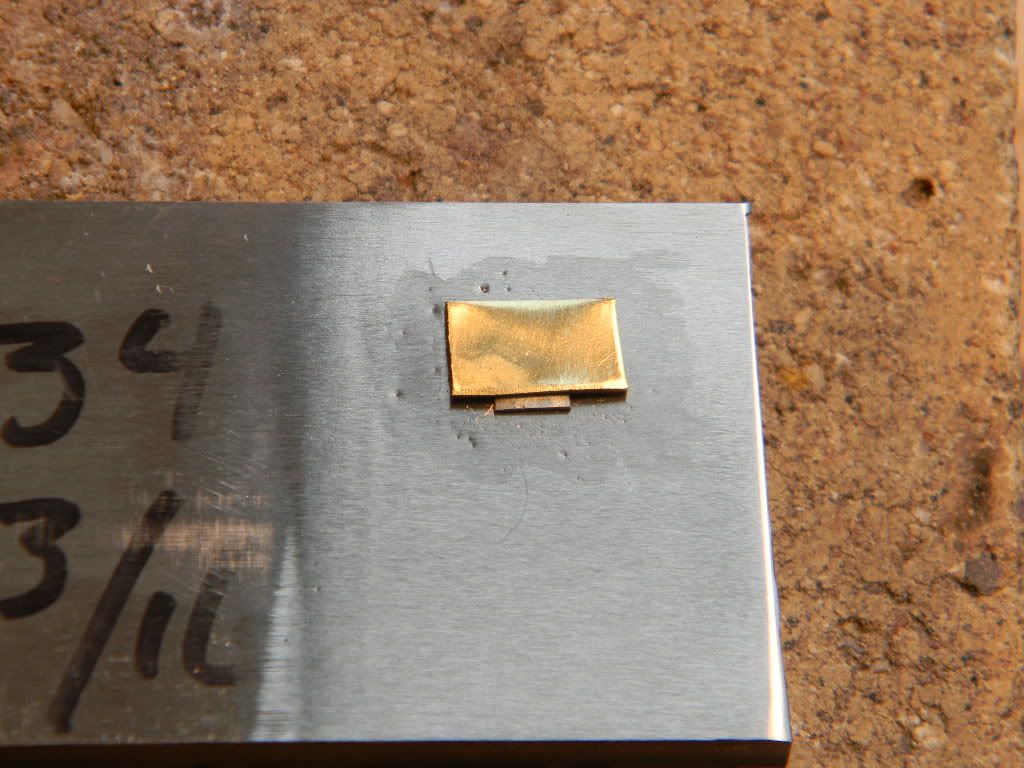

Thanks Brad, Tried again today, Sanded to 600g, washed with dish soap, fluxed and hammered the solder flat and cut into strips.

Cut some brass squares fluxed and set solder strip on the edge.

Used heat gun at 950 F*

No luck

Tried brass sandwich, no luck. I 'll try to get some stay clean but I'm going to forget the solder for this knife.

I'm anxious to move on to the handle.

Solder flowed better here. I used a flattened strip of solder.

The solder would melt but no flow.

After the first strip melted I added more strips in hopes they would go.

I tried a brass sandwich

Cut some brass squares fluxed and set solder strip on the edge.

Used heat gun at 950 F*

No luck

Tried brass sandwich, no luck. I 'll try to get some stay clean but I'm going to forget the solder for this knife.

I'm anxious to move on to the handle.

Solder flowed better here. I used a flattened strip of solder.

The solder would melt but no flow.

After the first strip melted I added more strips in hopes they would go.

I tried a brass sandwich

Last edited:

rhinoknives

Well-Known Member

Your shop is far to clean & organized!:biggrin:

Very Cool set up and machinery!

Laurence

www.rhinoknives.com

Very Cool set up and machinery!

Laurence

www.rhinoknives.com