Diamond G Knives

Well-Known Member

Let me say up front that this is NOT an attempt to start an argument or pick a fight, but to ask an honest questions.

I have recently been doing some stock removal blades due to the fact that I do not have my forge and hot shop set up while rebuilding my shop.

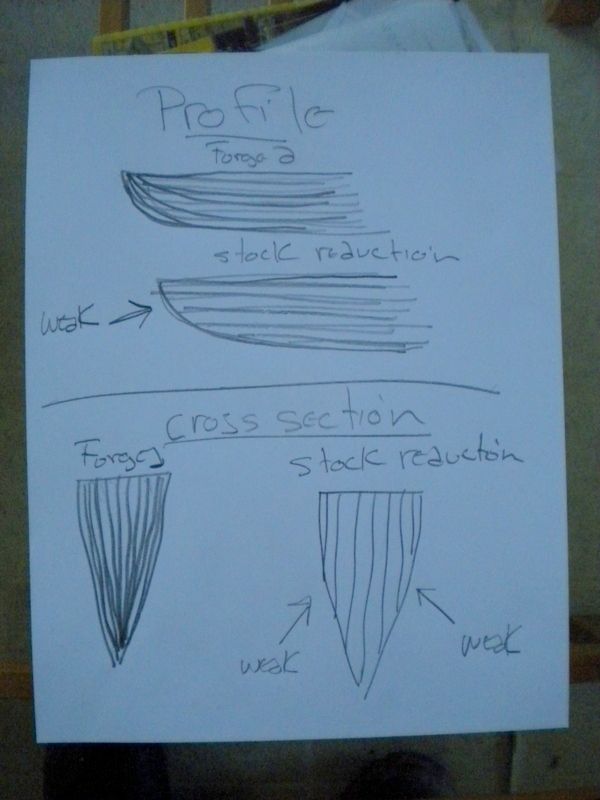

My question is this. With all things being equal, what does a knife blade benifit the most from? Are there certin things done while forging a blade that cannot be replicated with a stock removal blade during the heat treatment? I am a fan of the forged blade, and will get back to it as soon as I can, but other than being able to shape a piece of steel either from larger stock, or from odd shapes, what does forging give to the blade?

Again folks, Im trying to ask an honest question, not start a tussel! Would love to hear your opinions!

God Bless

Mike

I have recently been doing some stock removal blades due to the fact that I do not have my forge and hot shop set up while rebuilding my shop.

My question is this. With all things being equal, what does a knife blade benifit the most from? Are there certin things done while forging a blade that cannot be replicated with a stock removal blade during the heat treatment? I am a fan of the forged blade, and will get back to it as soon as I can, but other than being able to shape a piece of steel either from larger stock, or from odd shapes, what does forging give to the blade?

Again folks, Im trying to ask an honest question, not start a tussel! Would love to hear your opinions!

God Bless

Mike