Chris Railey

Well-Known Member

How many here are doing simple HT in a forge (with or without a pyrometer) or with a torch?

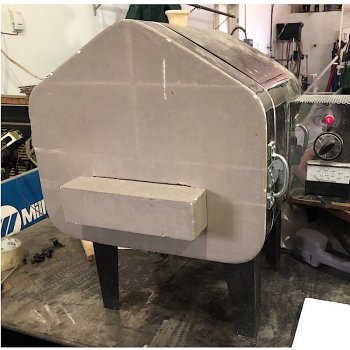

Exactly why I intend to add a pyrometer to my forge very soon. Because I do a lot of blacksmith stuff too its hard for me to drop $1500 to $2500 for a tool with mainly one purpose like a HT oven.I have my forge heat treating well in hand with pyrometer for judging heat control

With good pyrometer and judicious use of gas and air you can hold a good steady heat with +/- a few degrees

Lol I'm gonna wait for the short period of my life whenever Im working a real job but not married that's when I will get my HT oven

This https://www.artisansupplies.com.au/product/digital-thermometers/?c=dab83b10fbbeWhat are you using for meter and thermo-couple?