CDHumiston

KNIFE MAKER

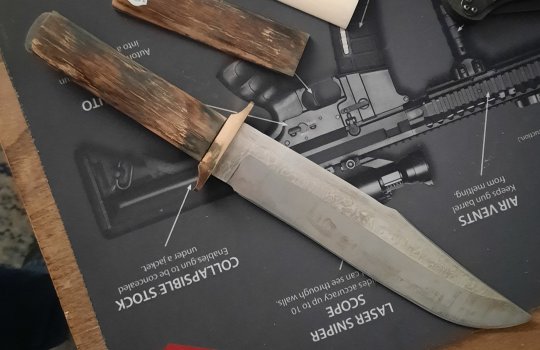

I'm at the point I need to decide what scales to put on my full tang Damascus Bowie knife.

I have a decent set of bone scales and a very nice set of Mammoth Ivory.

As you can see in the photos I'm going to lose 1/4" of handle if I go with the Mammoth...

The Mammoth Ivory is going to drive the price up considerably because they were $200.

What says the crowd?

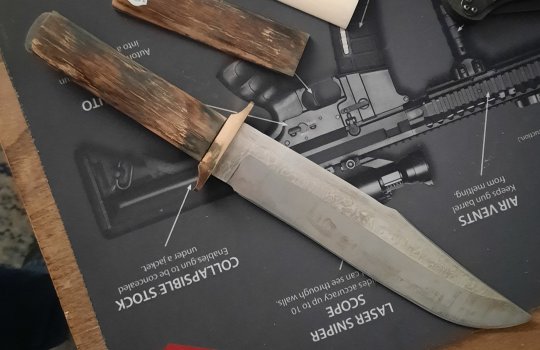

I have a decent set of bone scales and a very nice set of Mammoth Ivory.

As you can see in the photos I'm going to lose 1/4" of handle if I go with the Mammoth...

The Mammoth Ivory is going to drive the price up considerably because they were $200.

What says the crowd?