I may be posting in the wrong forum, but maybe you guys know what I'm talking about.

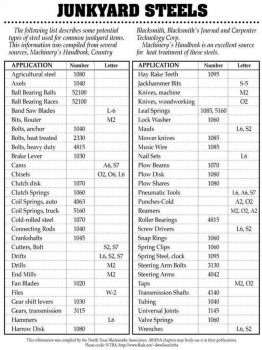

When I literally knew absolutely nothing about knife making (which I still have retained most of) I came across a picture chart of various hand tools and what kind of steel they were typically made from.

The problem is, I don't know if this chart was here, was on the bladeforum, or brittish blades, etc.

It had like a picture of a file, and said "O1 tool steel" (just an example, I'm not sure the makeup, and know that all new files are often case hardened mild steel) and showed punches and had it "L6 tool steel", a wrench, etc. Obviously I know this is not an absolute, but I thought it was a pretty cool reference.

I didn't think to save it, and for the life of me, I cannot find this picture ANYWHERE. I've tried and tried, and my googlefu is inadequate I guess.

The reason I ask this is because my wife is an ebay antiques dealer, and we are constantly getting old tools, etc. Whatever doesn't sell goes to the scrap yard at $0.08lb. Once I get my forge, to be able to utilize some of that would be fantastic.

Does anyone have this chart?

When I literally knew absolutely nothing about knife making (which I still have retained most of) I came across a picture chart of various hand tools and what kind of steel they were typically made from.

The problem is, I don't know if this chart was here, was on the bladeforum, or brittish blades, etc.

It had like a picture of a file, and said "O1 tool steel" (just an example, I'm not sure the makeup, and know that all new files are often case hardened mild steel) and showed punches and had it "L6 tool steel", a wrench, etc. Obviously I know this is not an absolute, but I thought it was a pretty cool reference.

I didn't think to save it, and for the life of me, I cannot find this picture ANYWHERE. I've tried and tried, and my googlefu is inadequate I guess.

The reason I ask this is because my wife is an ebay antiques dealer, and we are constantly getting old tools, etc. Whatever doesn't sell goes to the scrap yard at $0.08lb. Once I get my forge, to be able to utilize some of that would be fantastic.

Does anyone have this chart?