Mark Barone

Well-Known Member

Typically I think see swedges swooping up in a Bowie. Mine is swooping down. Is that unacceptable?

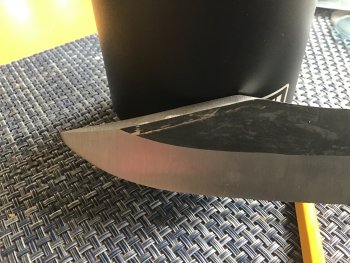

Typically I think see swedges swooping up in a Bowie. Mine is swooping down. Is that unacceptable? TCan I correct it? Can somebody draw a line on how it should be or should I go with this. The scratch on the black is just that a little scratch, not where I intended the swedge to go.[/ATTACH] This is still pre heat treat. Also knife OA is 12 inches. Does the handle look a little too big/long. I opted to do a full tang knife with a small integrated guard. I’m not ready for hidden yet.

Last edited: